Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018 391

• Motor NV implies that the motor attributes are derived from non-volatile

memory of a motor-mounted smart feedback device equipped with a serial

interface. Again, in this mode, only a minimal set of motor and motor

feedback (Feedback 1) are required to configure the drive.

In both Drive NV and Motor NV cases, the specific motor and motor feedback

attributes that are sent or not sent to the drive during configuration are identified

in the CIP Drive Set Attr Update Bits attribute table.

Motor and motor feedback attributes sent to the drive device in Drive NV or

Motor NV are merely to confirm that the controller and the drive have the

agreement on the values of attributes critical to scaling operation. If the NV

attribute values in the drive differ from the values set by the controller, the drive

will reject the values with General Status indicating an Invalid Attribute Value.

The current list of motor and motor feedback attributes sent to the drive in the

NV modes are as follows:

1. Motor Unit

2. Feedback 1 Unit

3. Feedback 1 Type

4. Feedback 1 Startup Method

5. Feedback 1 Cycle Resolution

6. Feedback 1 Cycle Interpolation

7. Feedback 1 Turns

8. Feedback 1 Length

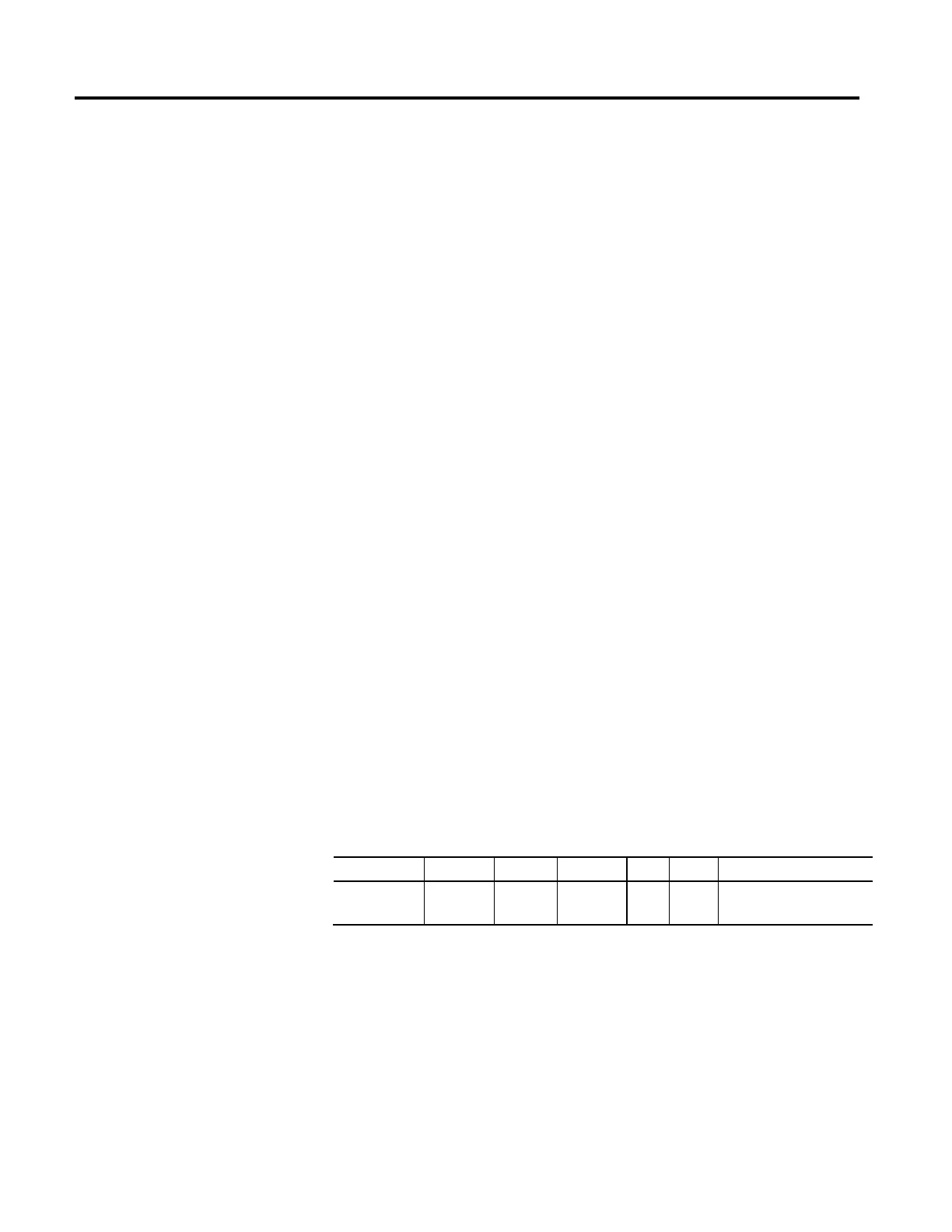

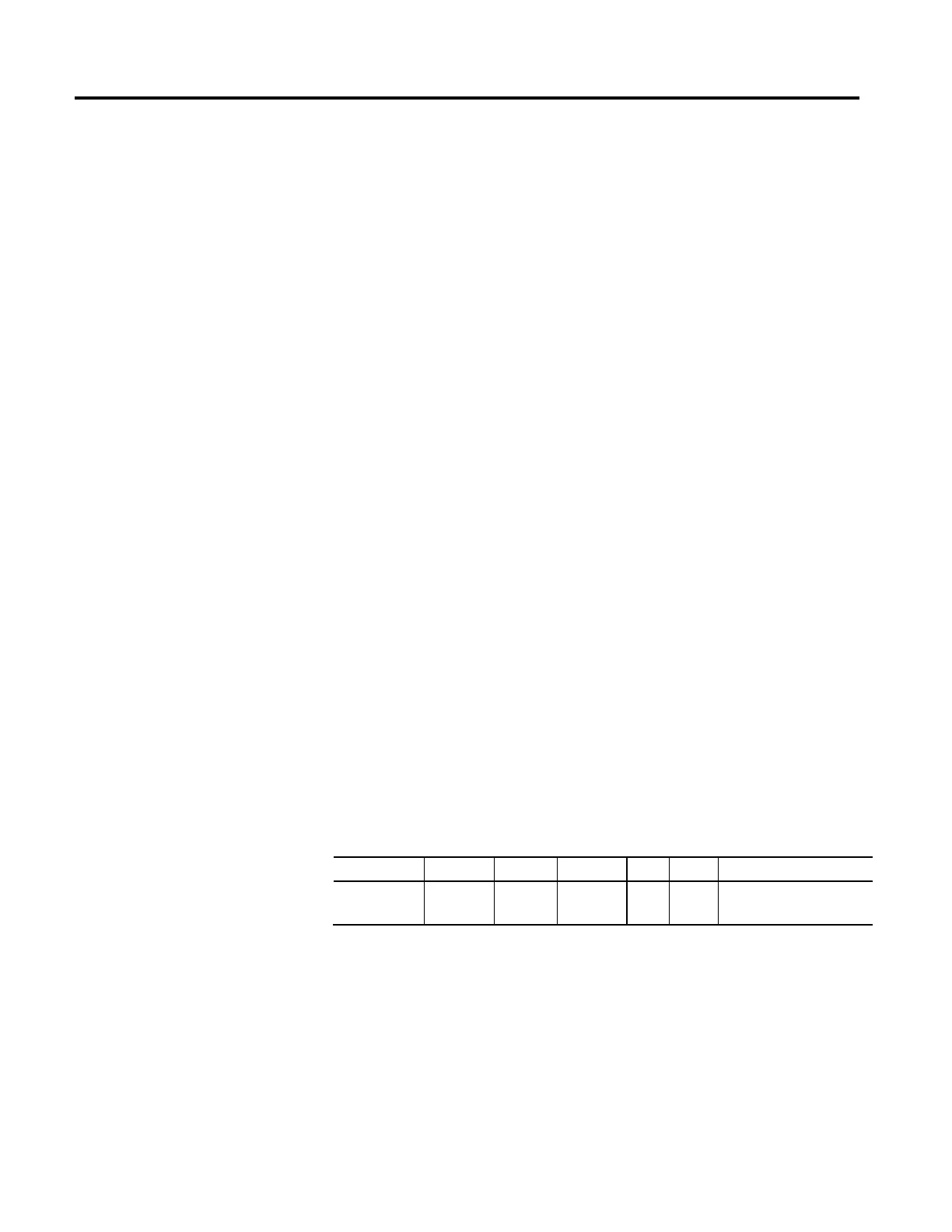

Motor Device Code

Usage Access Data Type Default Min Max Semantics of Values

Required Set/GSV UDINT 0

DB

0 2

32

-1 -

The Motor Device Code attribute is a unique number assigned to a motor catalog

number. This value is used to insure that the motor and integral motor mounted

feedback device configuration data delivered from the controller matches the

actual motor and feedback data connected to the drive.

This comparison is only valid in the case where the Motor Data Source is

Datasheet or Database driven and the motor is equipped with a smart feedback

device. If the codes do not match, a negative acknowledge is given by the drive.

Loading...

Loading...