438 Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018

7. Wait for "Mechanical Brake Release Delay" while brake releases.

8. Transition to Running (or Testing) state.

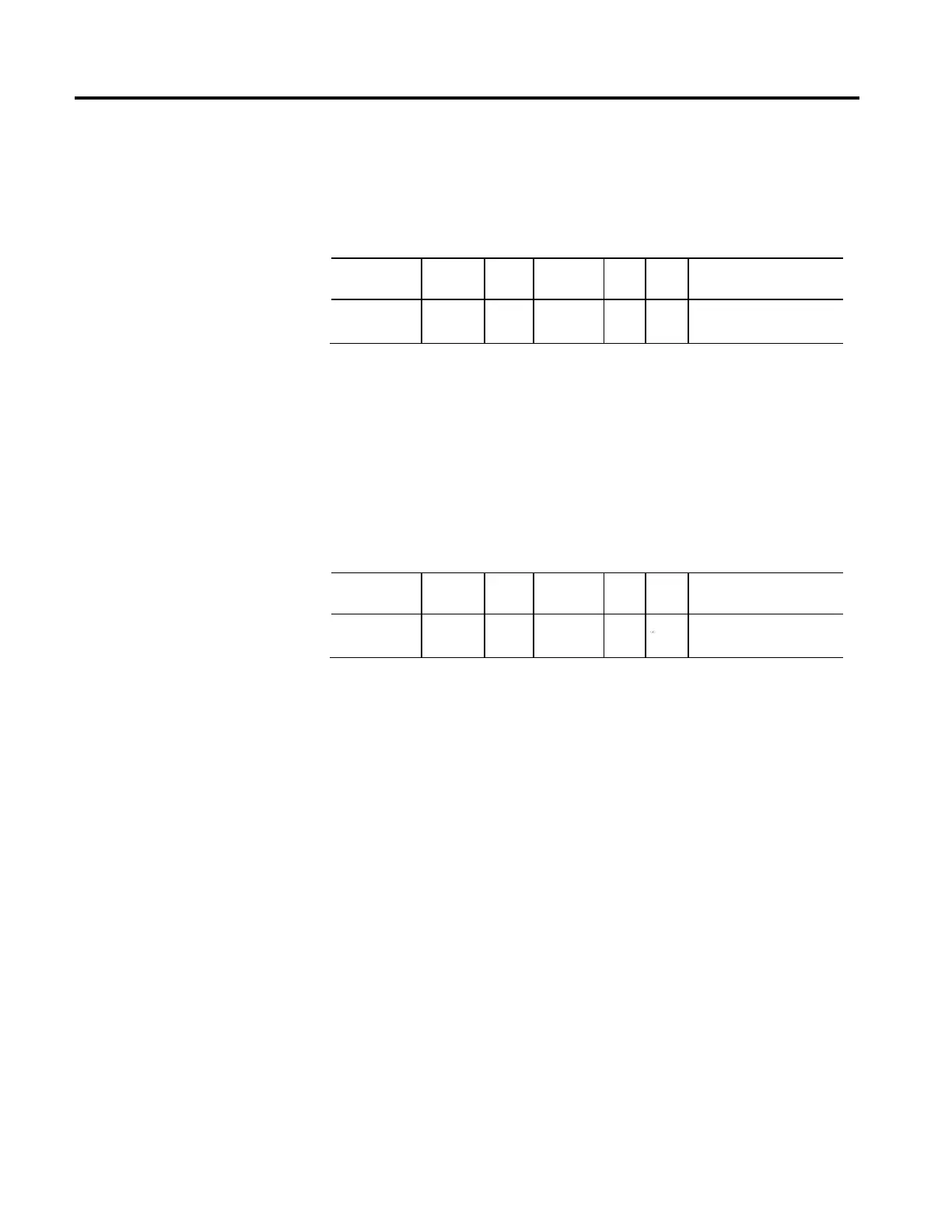

Mechanical Brake Engage Delay

Usage Access Data

Type

Default Min Max Semantics of Values

Optional - D Set/SSV REAL 0

FD

0 10

3

Seconds

When disabling the motion axis using a Category 1 Stopping Action, the

Mechanical Brake Engage Delay value determines the amount of time the device

power structure will remain enabled after the axis has decelerated to standstill.

This attribute allows time for an external mechanical brake to engage. The

configured Stopping Action determines the type of stopping sequence applied. If

supported, a Brake Proving operation is included in the Category 1 stopping

sequence prior to disabling the power structure.

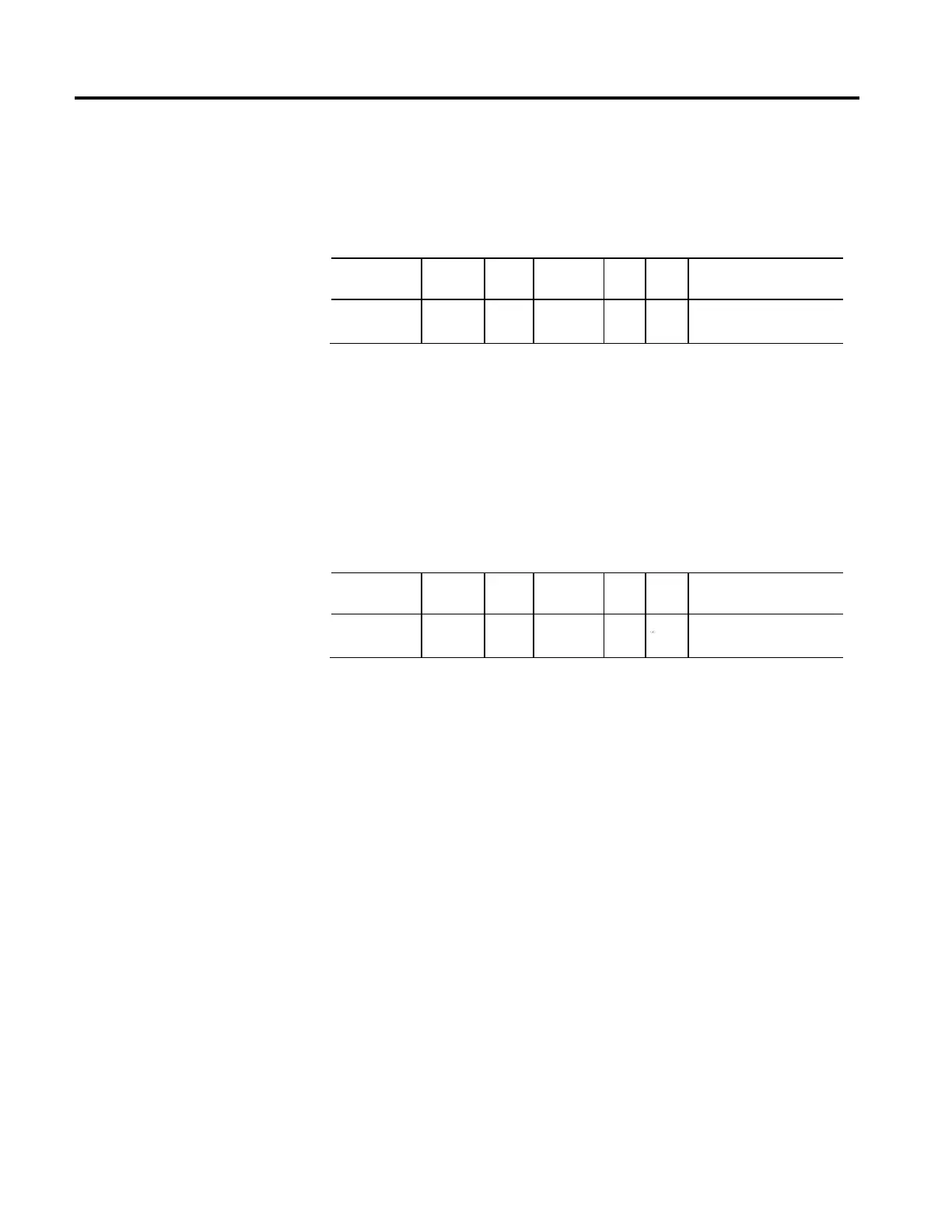

Zero Speed

Usage Access Data

Type

Default Min Max Semantics of Values

Optional - D Set/SSV REAL 1

FD

0

% Motor Rated

This attribute sets the speed threshold associated with the zero speed criteria of

the stop sequence. Zero Speed is specified as a percent of motor rated speed. When

Zero Speed Time attribute is supported, this attribute sets the speed threshold

where the zero speed timer starts. When the axis speed has been below the Zero

Speed threshold for Zero Speed Time the axis has satisfied the zero speed criteria.

In all but Category 2 stops, this results in action to engage the mechanical brake. If

this attribute is not supported, the zero speed threshold is left to the vendor’s

discretion and typically set to 1% of motor rated speed. Axis speed in the above

description is based on the Velocity Feedback signal, or in the case of a Frequency

Control drive, axis speed is based on Velocity Reference signal.

When supporting a Load Observer, the zero speed criteria is not based on the

Velocity Estimate since that signal can differ considerably from the actual speed of

the motor. When the Load Observer is configured to apply the Velocity Estimate

to the velocity loop summing junction as Velocity Feedback, the zero speed criteria

must be based on the velocity feedback signal input to the Load Observer.

Loading...

Loading...