Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018 437

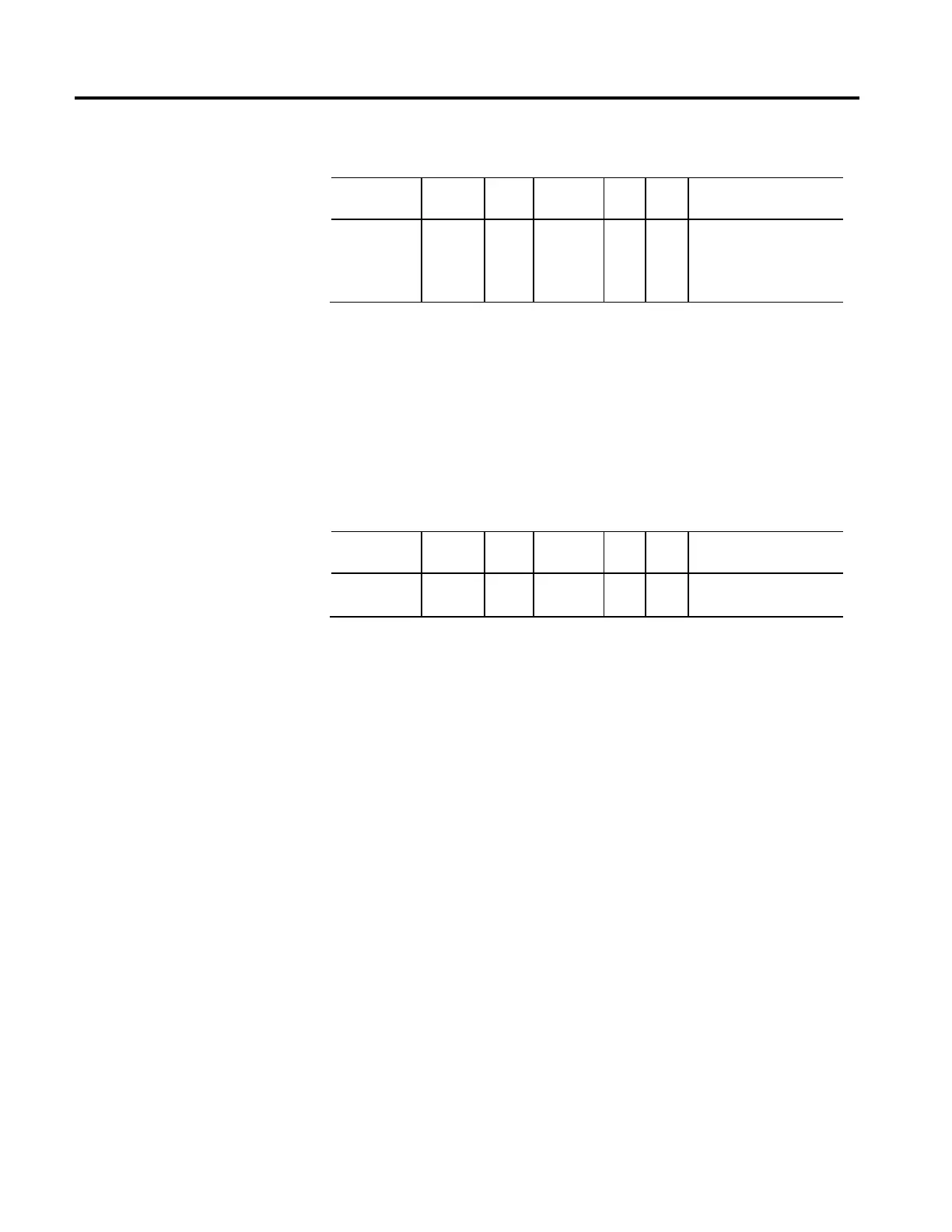

Mechanical Brake Control

Usage Access Data

Type

Default Min Max Semantics of Values

Optional - D Set/SSV USINT 0 - - Enumeration

0 = Automatic

1 = Brake Release

2...225 = Reserved

The Mechanical Brake Control attribute governs the operation of the drive's

Mechanical Brake Output that controls the mechanical brake mechanism. When

set to Automatic, the Mechanical Brake is under the control of the axis state

machine. The sequencing for the brake is described in detail by the Mechanical

Brake Engage Delay and Mechanical Brake Release Delay attributes. When set to

Brake Release, the brake is unconditionally released, and no longer under the

control of the axis state machine.

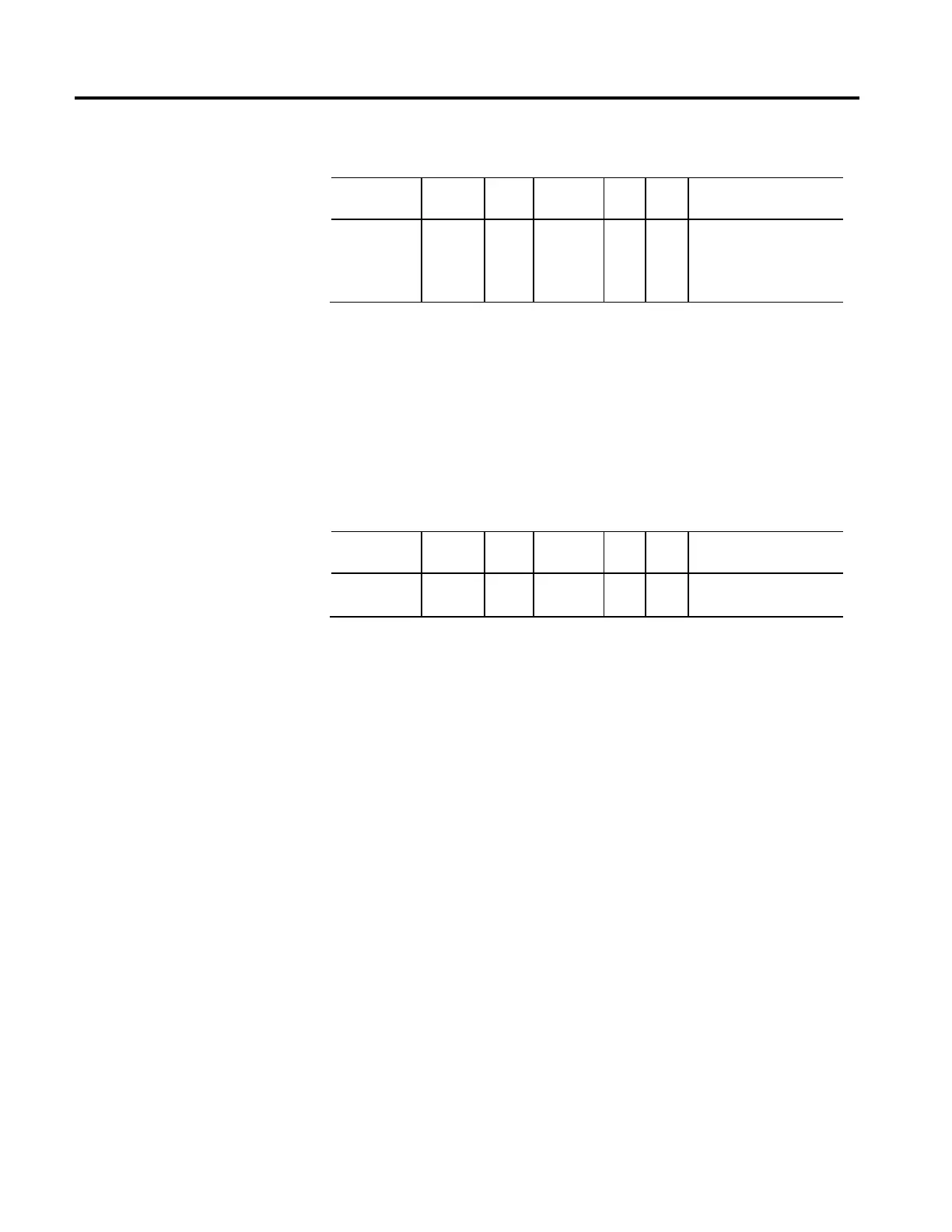

Mechanical Brake Release Delay

Usage Access Data

Type

Default Min Max Semantics of Values

Optional - D Set/SSV REAL 0

FD

0 10

3

Seconds

When enabling the axis, the Mechanical Brake Release Delay value determines the

amount of time the device will delay transition from the Starting state to the

Running or Testing states. This delay prevents any commanded motion of the

motion axis until the external mechanical brake has had enough time to disengage.

If supported, a Torque Proving operation is included in this sequence prior to

releasing the brake.

Enable Sequence:

1. Switch to Starting state.

2. Activate Resistive Brake contactor to connect motor to inverter power

structure.

3. Wait for "Resistive Brake Contact Delay" while Resistive Brake contacts

close.

4. Enable inverter power structure.

5. Perform (optional) Torque Proving operation to verify motor control of

load.

6. Activate Mechanical Brake output to release brake.

Loading...

Loading...