100 Rockwell Automation Publication 7000-UM202D-EN-P - May 2018

Chapter 2 Power Component Definition and Maintenance

b. Tighten the clamp to the proper force until you can turn the

indicating washers by the fingers with some resistance.

17. Once clamp force has been re-applied, tighten heatpipe locking nuts on

top of horizontal fin support (center nut at each sink) to 8 N•m

(6 lb•ft).

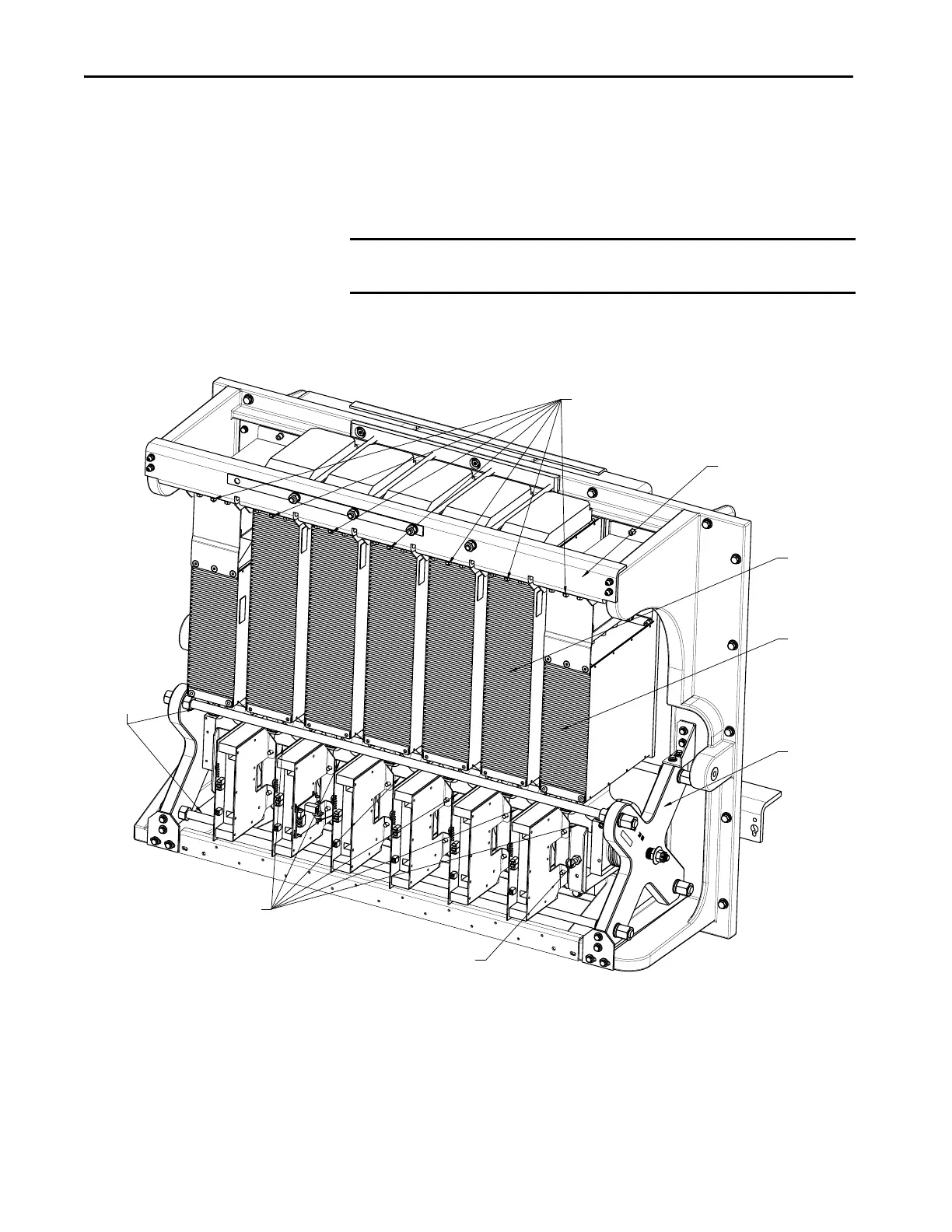

Figure 87 - Heatpipe PowerCage Module

PowerCage Gasket

To ensure all air movement is through the slots of the heatsinks, all possible air

leaks are sealed with a rubber gasket between the surface of the PowerCage and

heatsink module. The gasket maintains proper cooling of the SGCTs or SCRs.

IMPORTANT Do not re-tighten nylon shipping bolts on 6600V drives. They are for shipping

purposes only.

Heatpipe locking nuts

Horizontal Fin Support

Clamp Head

Glass Rods

Clamp

Head

White Heatpipe

Retaining Bracket

Nylon Shipping Bolt

Heatpipe

End Position

Heatpipe

Loading...

Loading...