Rockwell Automation Publication 7000-UM202D-EN-P - May 2018 211

Encoder Use and Torque Capabilities Appendix H

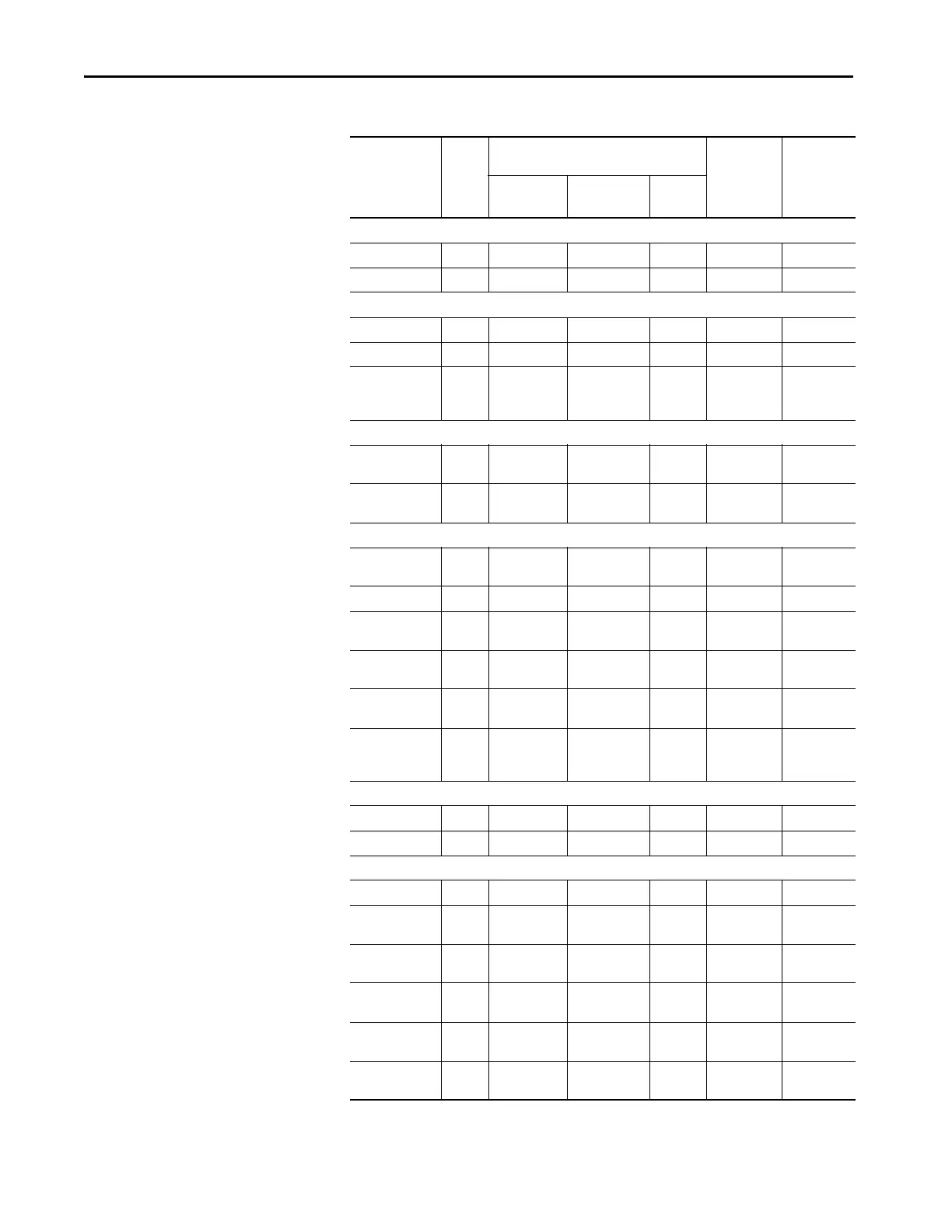

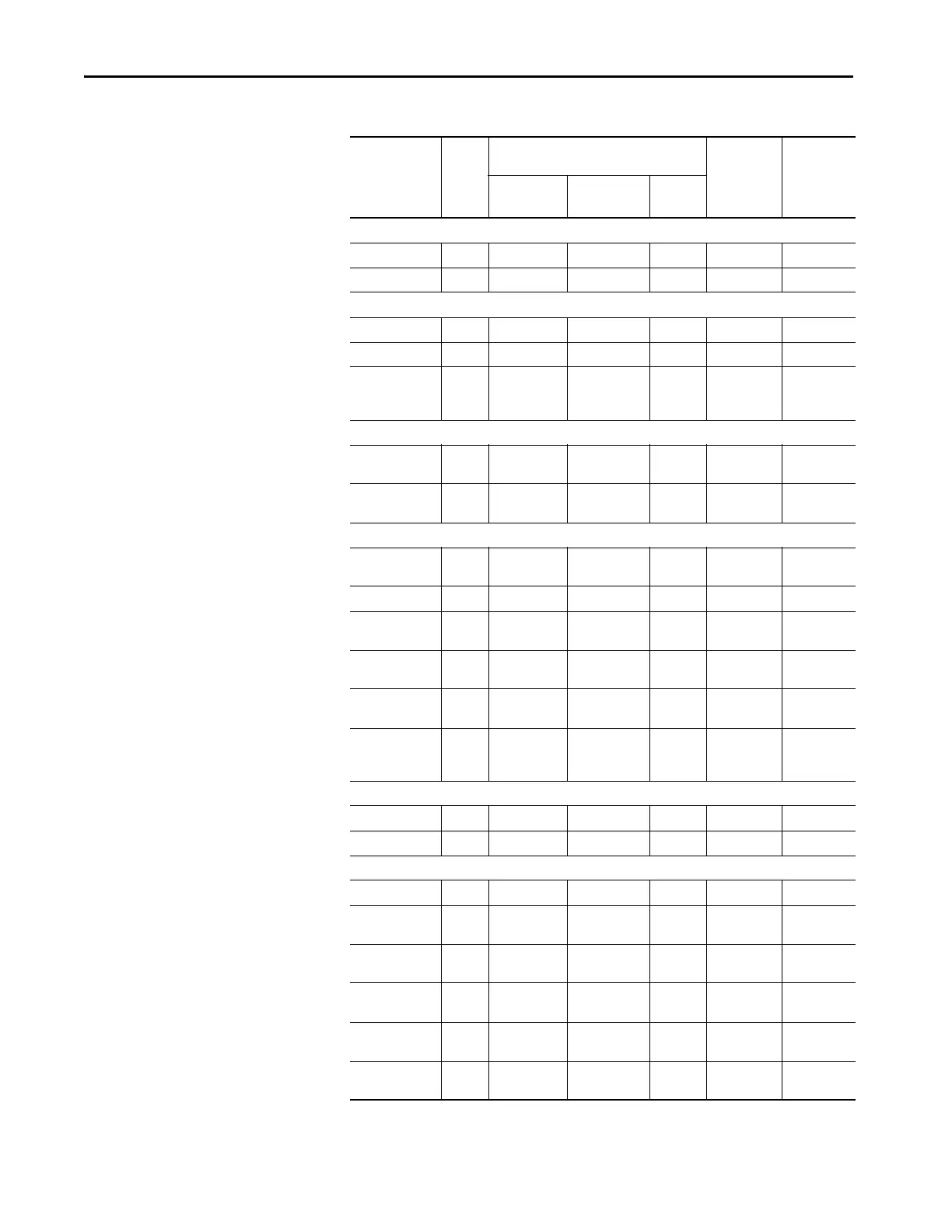

Table 23 - Typical Application Load Torque Profiles

Application Load

Torque

Profile

Load Torque as Percent of Full-Load Drive

Torque

Required

Drive Service

Duty Rating

Encoder

Required for

Extra

Starting

Torque?

Break-

away

(1)

Accelerating

(2)

Peak

Running

AGITATORS

Liquid CT 100 100 100 Heavy Yes

Slurry CT 150 100 100 Heavy Yes

BLOWERS (centrifugal)

Damper closed VT 30 50 40 Normal No

Damper opened VT 40 110 100 Normal No

CHIPPER

(WOOD)—

starting empty

CT 50 40 200 Contact

factory

No

COMPRESSORS

Axial-vane,

loaded

VT 40 100 100 Normal No

Reciprocating,

starting unloaded

CT 100 100 100 Contact

factory

Yes

CONVEYORS

Armored Face CT 175 150 200 Contact

factory

Yes

Belt type, loaded CT 150 130 100 Heavy Yes

Drag type CT 175 150 100 Contact

factory

Yes

Screw type,

loaded

CT 200 100 100 Contact

factory

Yes

DRAG LINE CT 100 200 200 Contact

factory

Yes

EXTRUDERS

(rubber or

plastic)

CT 150 150 100 Contact

factory

Yes

FANS (centrifugal, ambient)

Damper closed VT 25 60 50 Normal No

Damper open VT 25 110 100 Normal No

FANS (centrifugal, hot gases)

Damper closed VT 25 60 100 Normal No

Damper open VT 25 200 175 Contact

factory

No

FANS (propeller,

axial flow)

VT 40 110 100 Normal No

GRINDING MILL

(Ball/Sag Mill)

CT 175 180 100 Contact

factory

Yes

HOISTS CT 100 200 200 Contact

factory

Yes

KILNS (rotary,

loaded)

CT 250 125 125 Contact

factory

Yes

Loading...

Loading...