IS-200A

12. Troubleshooting

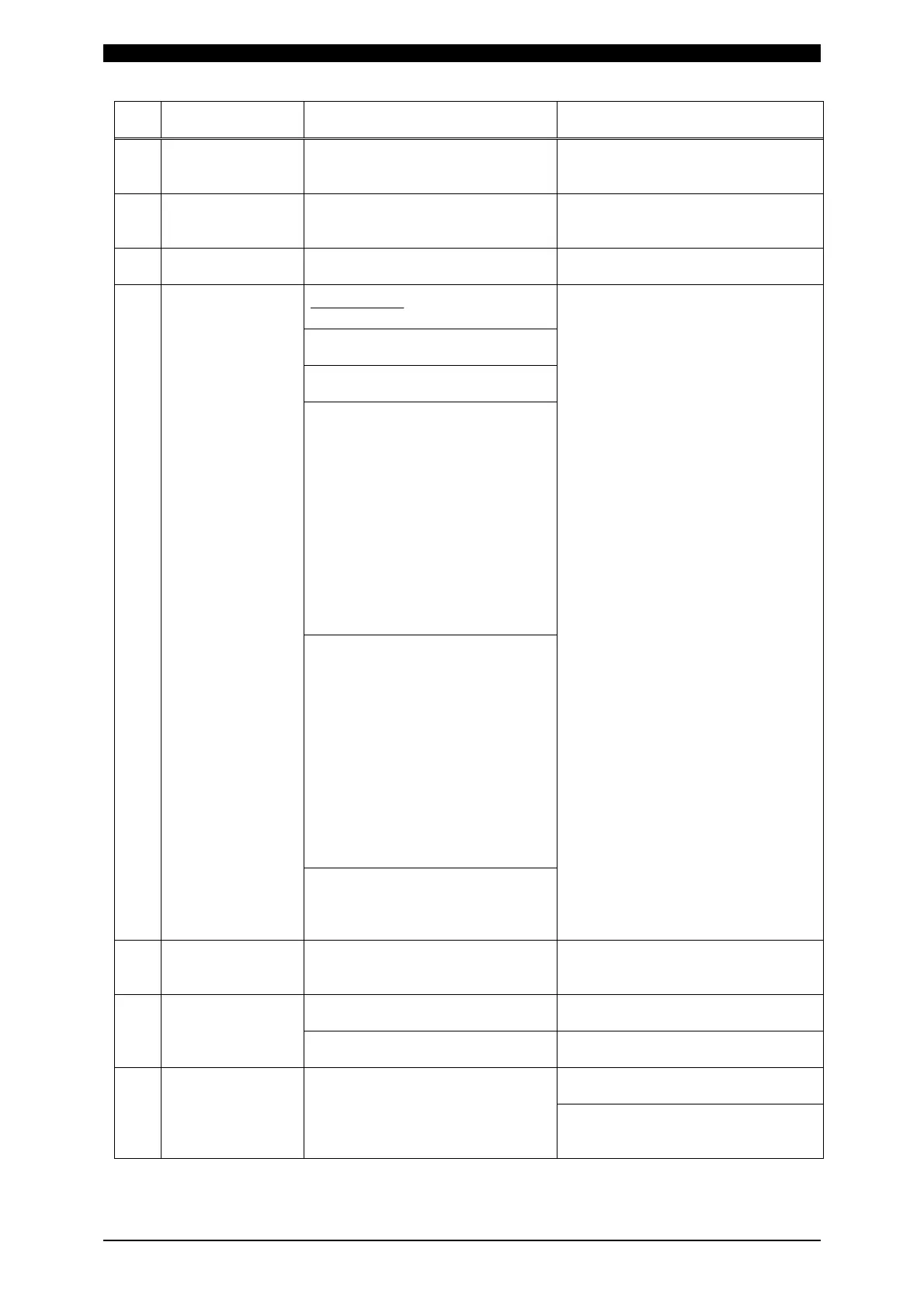

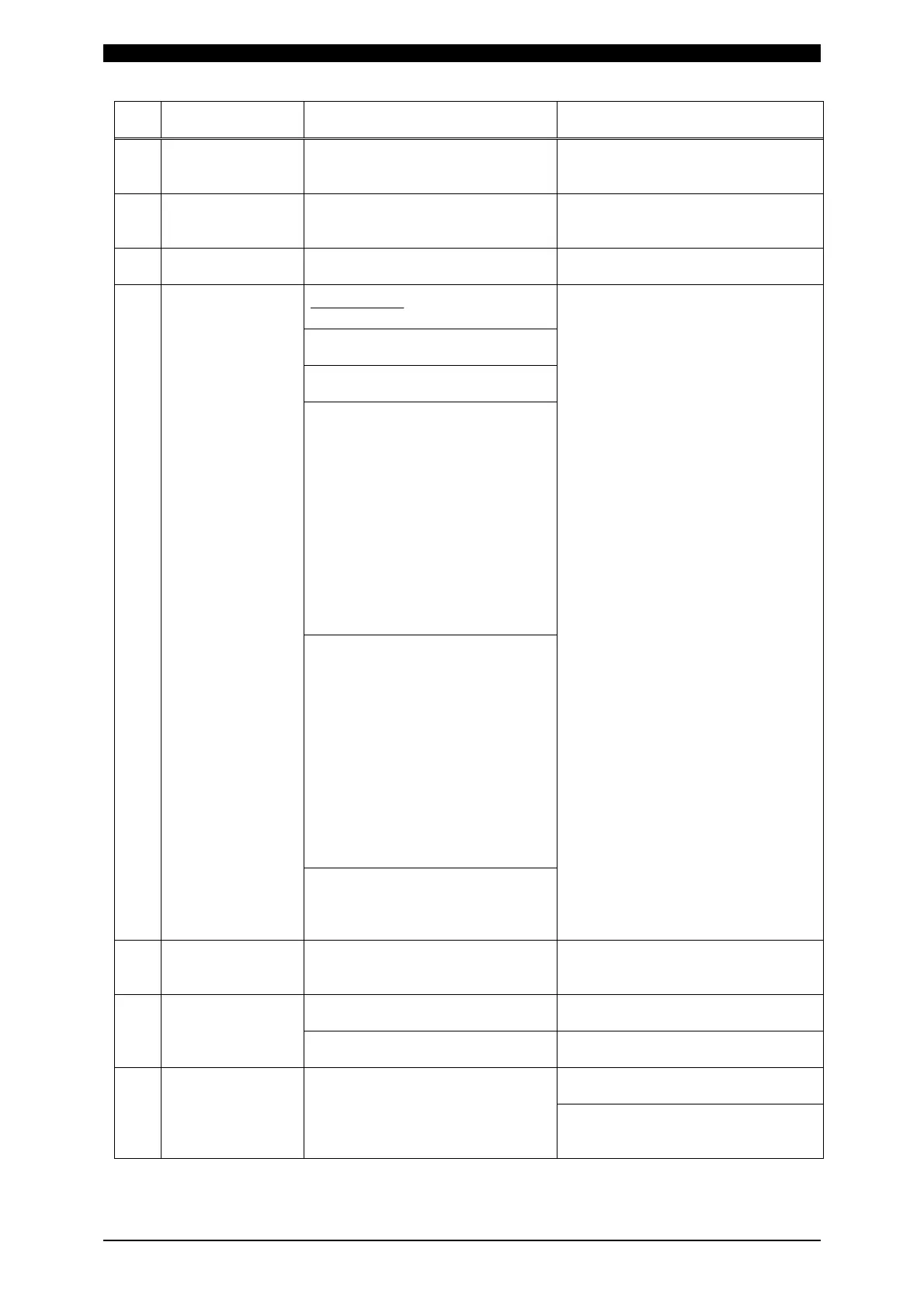

12-2

Fault

code

Contents Cause Measures

E-07 Pulse width error

Pulse width of welding current is

out of PULSE HIGH setting range

on MONITOR SET screen.

Check workpiece and welding

electrode.

E-08

Insufficient number

of weld counts

Counted number of welds is less

than WELD COUNT setting.

Add required number of welds to

make up for insufficiency. (See 4.

(8)(a).)

E-09 Step end

STEPPER COUNT has completed

final step.

Dress or replace tip, then reset step.

(See 6. (1)(2).)

E-10

Schedule setting

error

RATIO P/S

HEAT setting

> 200

Correct each setting.

UP SLOPE or DOWN SLOPE is

longer than WELD.

The WELD1, WELD2, and WELD3

values are all “0.”

Although the current in the

subsequent stage is lower than that

in the previous stage or the

currents are equal, Upslope time is

set in the subsequent stage and

COOL is not set between the

previous stage and the subsequent

stage.

Example)

WELD1 = 20 ms 3.0 kA

WELD2 = 40 ms 2.0 kA

COOL1 = 0 ms

UP2 = 10 ms

Although the current in the

subsequent stage is higher than

that in the previous stage or the

currents are equal, Downslope time

is set in the previous stage and

COOL is not set between the

previous stage and the subsequent

stage.

Example)

WELD2 = 50 ms 3.0 kA

WELD3 = 70 ms 4.0 kA

COOL2 = 0 ms

DOWN2 = 20 ms

lthough STEPPER MODE is set to

ON, STEPPER COUNT of STEP

number set for START ON STEP#

are all “0.”

E-11 Increase ratio error

HEAT setting, including RATIO

setting is larger than max. value of

current, voltage, or power setting.

Correct each setting. (See 4. (9).)

E-12 Emergency stop

External emergency stop input

circuit is open.

Rectify cause of emergency stop, and

then close stop circuit.

Power supply for external input is

not connected.

Check external input signal for proper

connection.

E-13 Overcurrent

Primary current above the limit is

detected.

Check for welding transformer and

welding electrode problems.

Check that the toroidal coil or the

voltage detecting cable is connected

in the secondary control.

Loading...

Loading...