IS-200A

4. How to Operate Screens

4-26

(9) STEPPER COUNT Screen

The Power Supply can change the level of the welding current depending on the

welding conditions. The function to increase the welding current is called the “step-up”

function, and that to decrease the welding current is called the “step-down” function.

Set the step-up or step-down timing based on the number of welds.

(c)

-STEPPER COUNT VALVE # 1

START ON STEP # 3

RATIO COUNT RATIO COUNT

STEP1 100% 0000 STEP6 100% 0000

STEP2 100% 0000 STEP7 100% 0000

STEP3 100% 0000 STEP8 100% 0000

STEP4 100% 0000 STEP9 100% 0000

STEP5 100% 0000

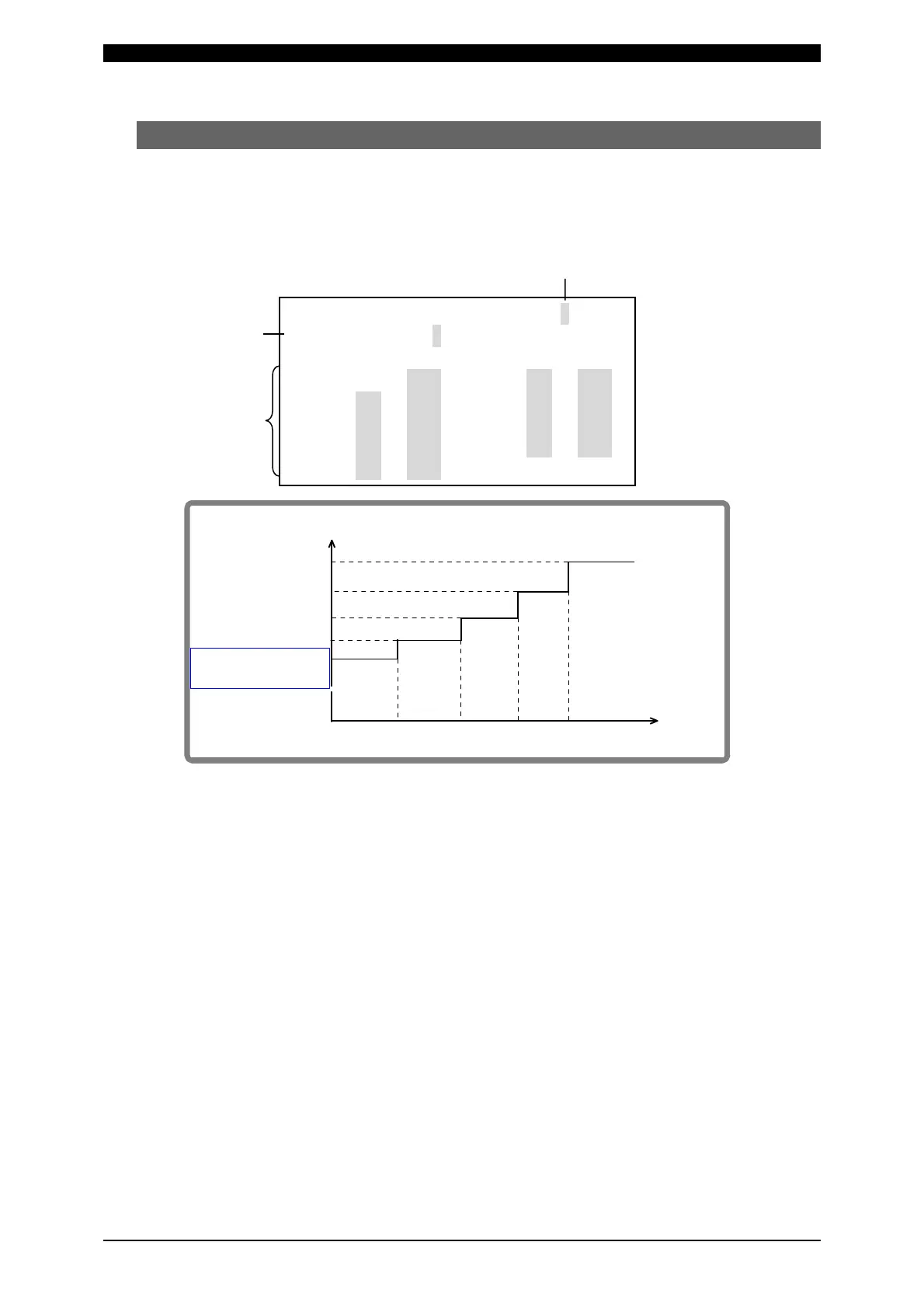

As shown in the above figure, the current is stepped up or down to the value for

STEP2 following completion of the specified number of welds for STEP1.

Similarly, the current is stepped up or down to the value for STEP3 following

completion of the specified number of welds for STEP2.

(a) START ON STEP #

The counting of welds starts from the STEP set here.

If, for example, you select START ON STEP #3 as shown above, welds will be

counted from the first weld in STEP3, even if welding for the first time. Further,

the welding current will be increased (or reduced) by the extent you have set this

value for STEP3.

Set the desired STEP No. 1–9 for VALVE1 and VALVE2 respectively.

(b) STEP 1–9

Set the welding current step-up ratio (RATIO) and the number of welds (COUNT)

for each STEP. The sequence will proceed to the next STEP when the set

number of welds is reached.

(c) VALVE #

Make settings for (a) and (b) above for each valve number. Change the number

to set the schedule for each valve.

(b)

(a)

~

~

Set value of STEP 1

Set value of STEP 2

Set value of STEP 3

Set value of STEP 4

Set value of STEP 5

Current

(Fixed to 100%)

STEP1 STEP2 STEP3 STEP4 STEP5

Number of

welds

Loading...

Loading...