IS-200A

12. Troubleshooting

12-4

(2) When a Welding Does not Start Even if the Start

Signal is Input

When a welding does not start even if the start signal (2ND STAGE signal) is

input, the following causes can be thought.

READY does not light up.

Start signal is shorter than DELAY START SET time setting.

Start signal is input while the END signal is output.

Start signal is input during communicating with the MA-627A.

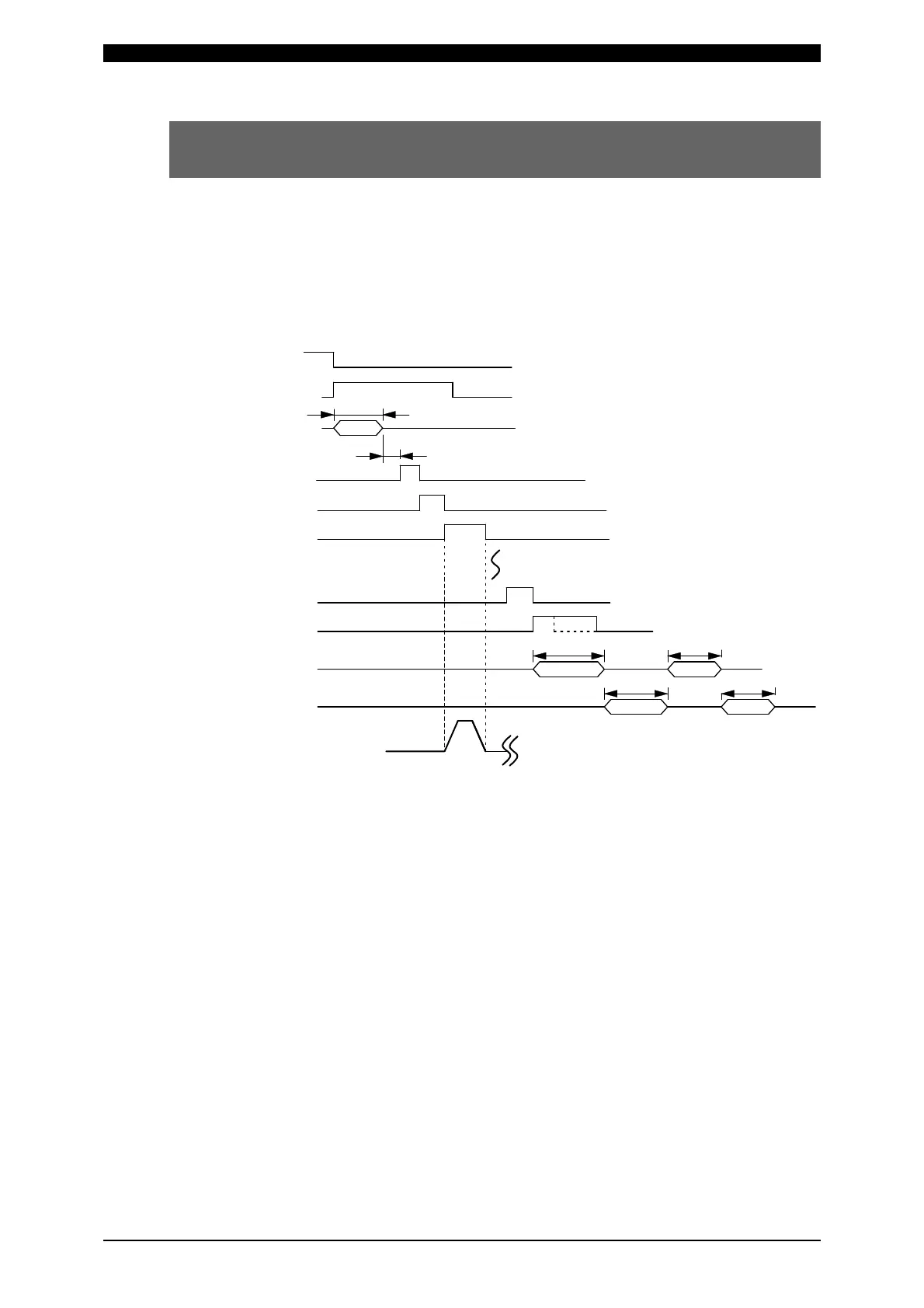

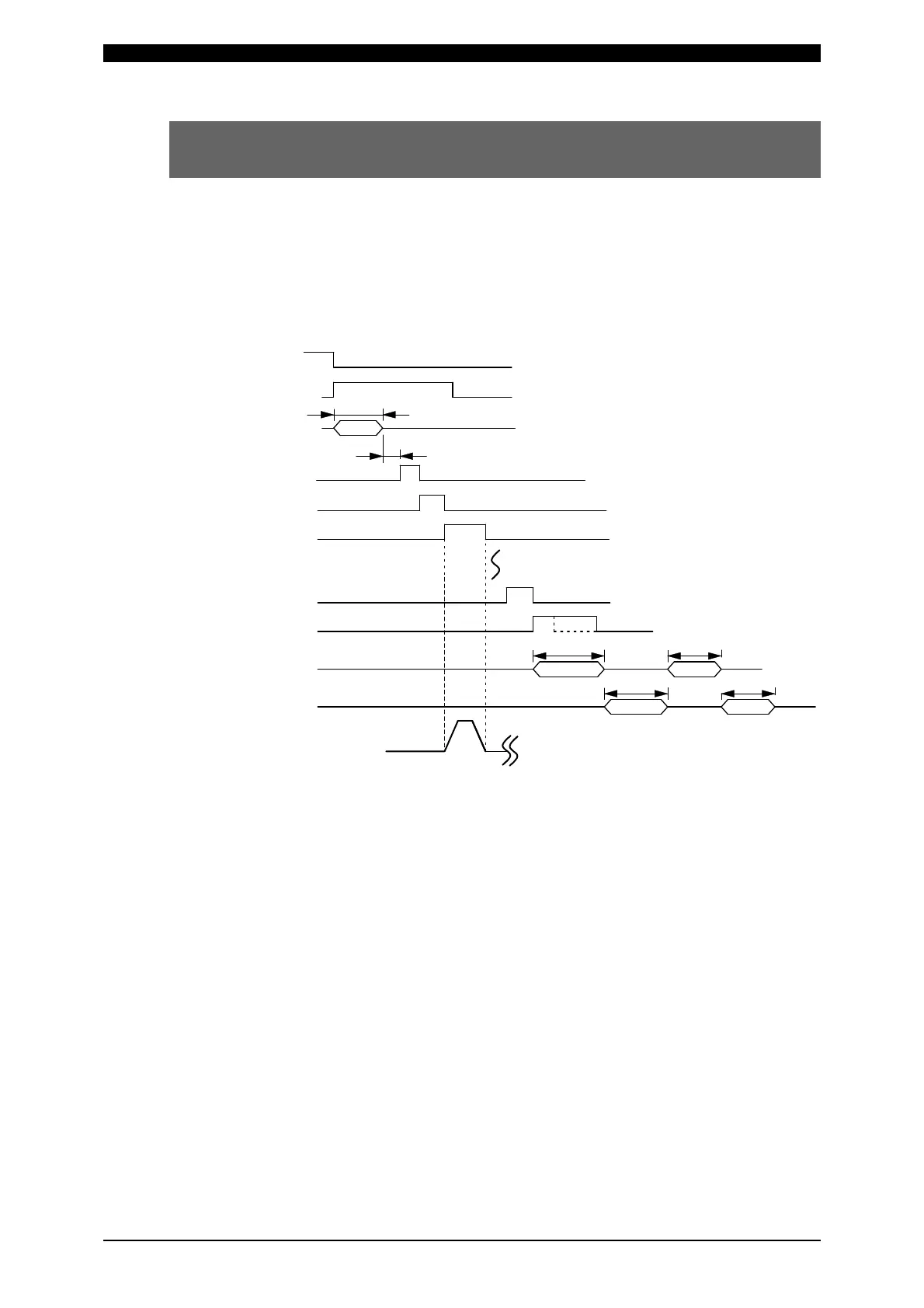

Ta

T

Tb1 Tb2

Tc1 Tc2

SQD

SQZ

WE1

HOLD

END

T : DELAY START SET

2ND STAGE

Ta : Data communication

time at start

(Note 1)

(Note 2)

(Note 3)

(Note 4)

CAUTION

HEAT Ⅰ

Tb : MA-627A Data

transmission time at end

transmission time at end

Tc : External comm. Data

(Note 1) When the next start signal is received while the monitor error is

displayed on the MA-627A, the caution signal is turned OFF and the

previous screen is displayed.

At this time, the data is transferred to the MA-627A from the Power

Supply. The start signal is not received while the data is transferred.

(Ta: 31

ms max. in the figure above.)

When the monitor error is displayed, input the start signal more than

(Ta + T) time.

(Note 2) When the sequence ends, the END signal is output after HOLD. The

start signal is not received while the END signal is output.

To make start takt faster, lower the output time of END signal. (Can

be set in 10-ms increment. The minimum value is 10

ms.)

Loading...

Loading...