IS-200A

12. Troubleshooting

12-1

12. Troubleshooting

(1) Fault Code List

In the event of a problem with the Power Supply, the MA-627A displays the fault

code and message.

In such cases, read this section carefully, then inspect the equipment and take the

necessary countermeasures. If you have any questions, consult us or your

distributor.

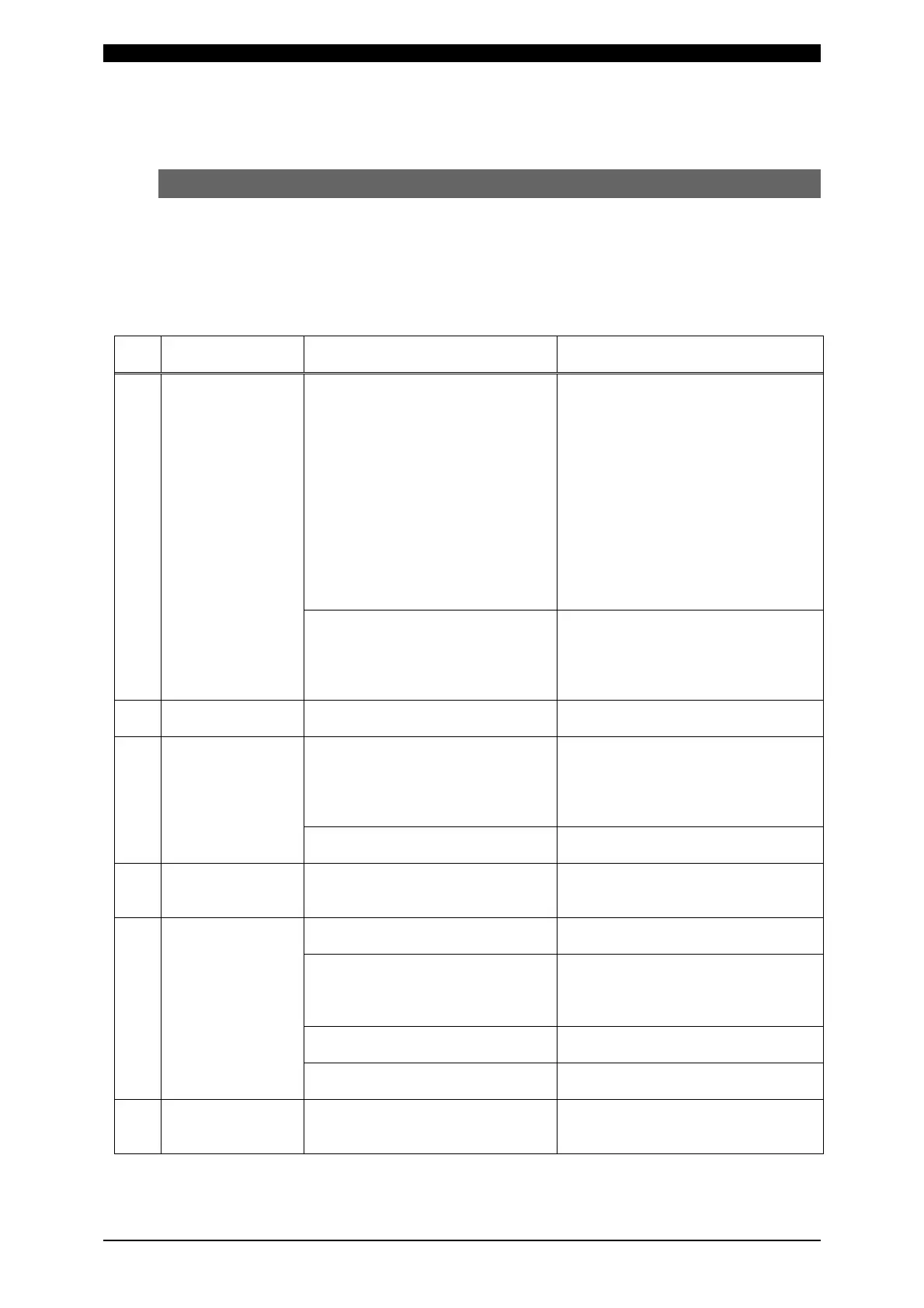

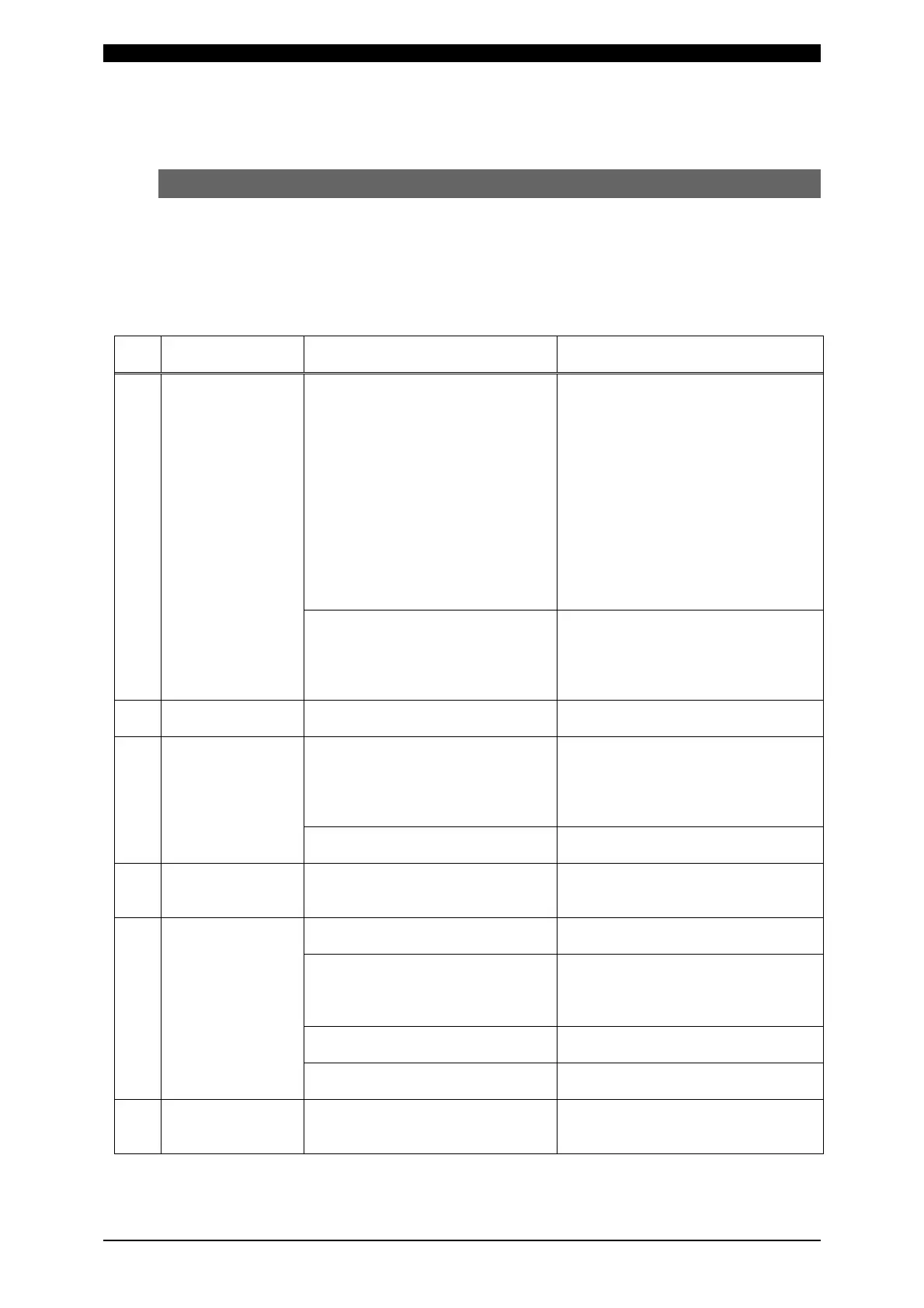

Fault

code

Contents Cause Measures

E-01 Setting data error

The welding schedule data is

different from the programmed one.

Check all the settings. If the data in

memory is damaged, the following

are possible causes:

Generation of powerful power

supply or electrostatic noise

Abnormal supply voltage

resulting, for example, from

lightening or induced lightening

Flash memory’s rewrite limit

exceeded

If the error occurs again after

initialization, the Power Supply needs

repair. Contact us.

When writing data in bi-directional

communication mode at external

communication, data which is out of

the range is written or data format is

wrong.

Check the write data.

E-02 Start input error

Cable to input start signal is broken,

and a parity check error is detected.

Check start signal input cable.

E-03

External

transformer

thermostat error

Temperature of welding

transformer rises and external

thermostat input circuit opens.

Lower temperature of transformer.

When using water-cooled

transformer, properly adjust

temperature and flow rate of cooling

water.

External signal input power is not

connected.

Check external input signal for proper

connection.

E-04

IGBT thermostat

error

Internal temperature of equipment

rises and thermostat for power

transistor in power unit is open.

Ensure that the duty cycle does not

exceed the specified value. (See 9.

(3).)

E-05

No-current error

(Secondary or

primary current is

not detected)

Squeeze of welding electrode is not

sufficient.

Adjust squeeze of welding electrode

adequately.

SQD or SQZ time is too short.

Check setting of SQD or SQZ time to

determine whether it is too short. (Set

SQD or SQZ time to a period longer

than the stroke time of the electrode.)

NO CURRENT LEVEL is high.

Set a lower NO CURRENT LEVEL.

(See 4. (8)(c).)

Fuse inside the equipment is blown.

The fuse needs replacement. Contact

us.

E-06 Current error

Welding current is out of

CURRENT setting range on

MONITOR SET screen.

Check for stained welding electrode

or loose cable connection.

Loading...

Loading...