M19-2101 REVISION 2.0 DVNEXT RHEOMETER - OPERATIONAL MANUAL

A.4 Verifying calibration

• Determine the appropriate sample volume. Refer to Table A-1 to determine the correct sample volume

required for the spindle to be utilized.

• Select a AMETEK Brookfield Viscosity Standard fluid that will give viscosity readings between 10% and

100% of full-scale range. Refer to Appendix B for viscosity ranges of cone spindles. AMETEK Brookfield

uses mineral oil viscosity standard fluids to calibrate Wells Brookfield Cone/Plate Rheometers at the

factory. AMETEK Brookfield recommends that customers use mineral oil viscosity standard fluids when

you perform a calibration check.

• If you decide to use a silicone viscosity standard fluid, do not use a fluid with a viscosity value greater

than 5000 cP with a Cone/Plate. AMETEK Brookfield oers a complete range of mineral oil viscosity

standards suitable for use with Cone/Plates for viscosities above 5,000 cP or shear rates above 500

sec-1; see Table E-2 in Appendix F for a list of available fluids.

• It is best to use a viscosity standard fluid that will be close to the maximum viscosity for a given cone

spindle/speed combination.

• Example: DVNext LV Rheometer, Cone Spindle CPA-42Z, AMETEK Brookfield Viscosity Standard

having a viscosity of 9.7 cP at 25°C.

• At 60 RPM, the full-scale viscosity range is 10.0 cP. Thus, the Rheometer reading should be 97%

torque and 9.7 cP viscosity ± 0.197 cP. The allowable error (±0.197 cP) is a combination of Rheometer

accuracy and fluid tolerance (refer to Interpretation of Calibration Test Results in Appendix F).

• With the motor o, remove the sample cup and place the viscosity standard fluid into the cup.

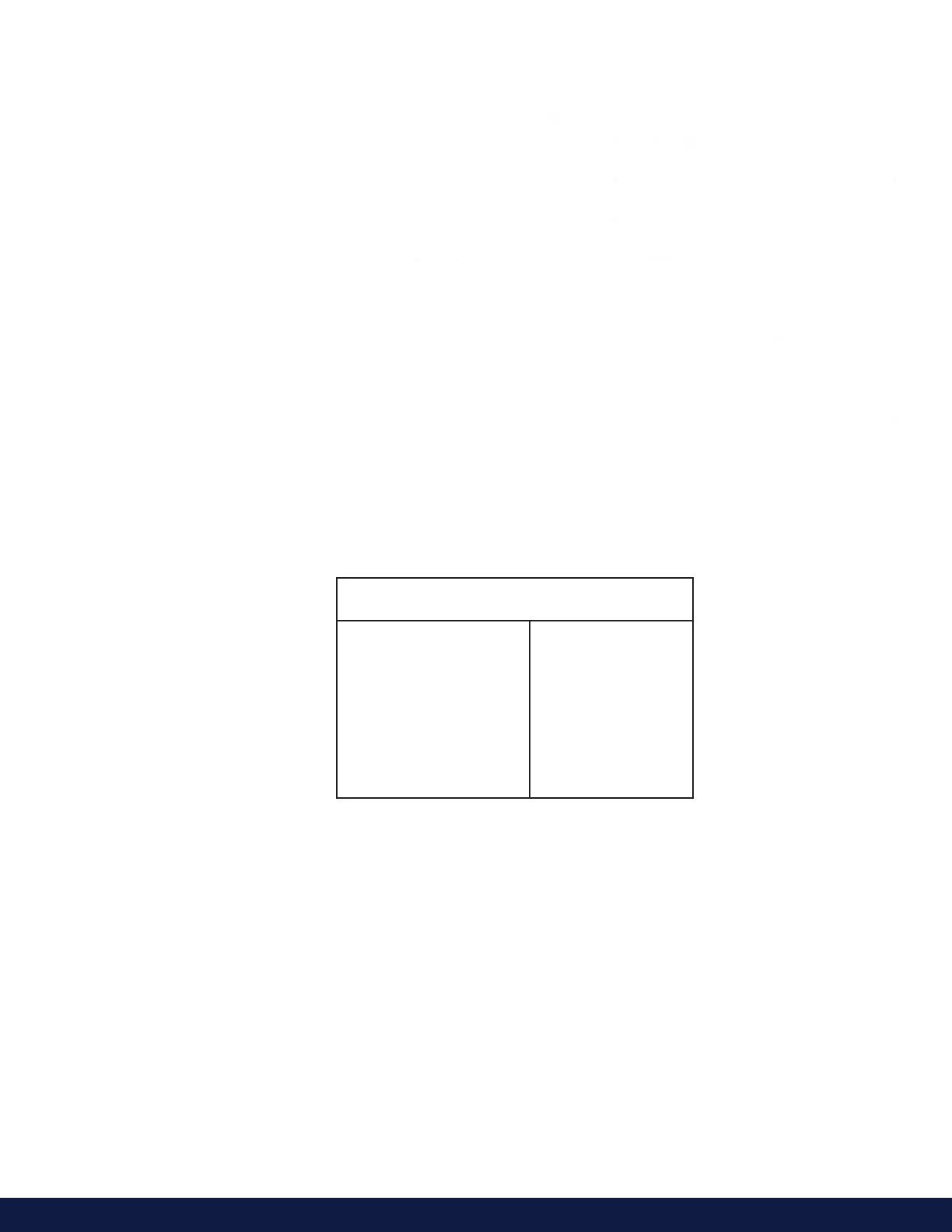

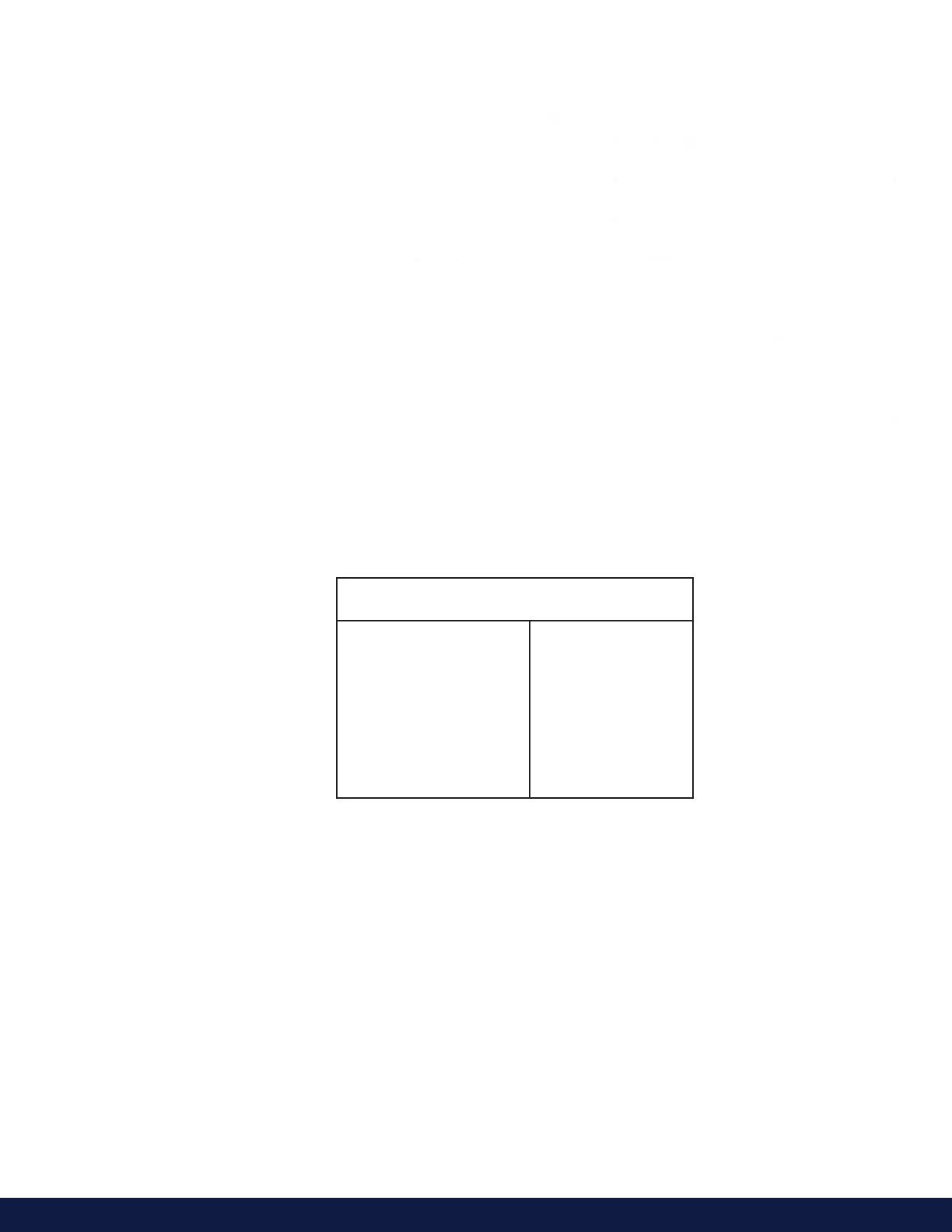

Table

A-1

CONE PART NO. SAMPLE VOLUME

CPA-40Z or CPM-40Z 0.5 mL

CPA-41Z or CPM-41Z 2.0 mL

CPA-42Z or CPM-42Z 1.0 mL

CPA-51Z or CPM-51Z 0.5 mL

CPA-52Z or CPM-52Z 0.5 mL

• Attach the sample cup to the Rheometer and allow enough time for the sample, cup and cone to reach

temperature equilibrium (25°C ±0.1°C).

• Go to Configure Viscosity. Set the desired parameter, e.g. Speed, Spindle, Sample ID, etc. Set the End

Condition for Time 00:00:00. Press Run.

• Measure the viscosity and record the readings in both % torque and centipoise (cP).

• Verify that the viscosity reading is within the allowable 1% deviation, as explained earlier, for the specific

viscosity standard fluid(s) that you are using.

• The CPE, CPM, or CPA designation on the cone spindle indicates use with Electronic Gap Setting Cone/

Plate Rheometers/Rheometers only.

Loading...

Loading...