Dansensor® LeakPointer 3/3

+

EN User Guide 13

P/N 380064-F

06/2021

Measuring principle

The actual leak testing takes place inside the vacuum chamber. The procedure is as follows:

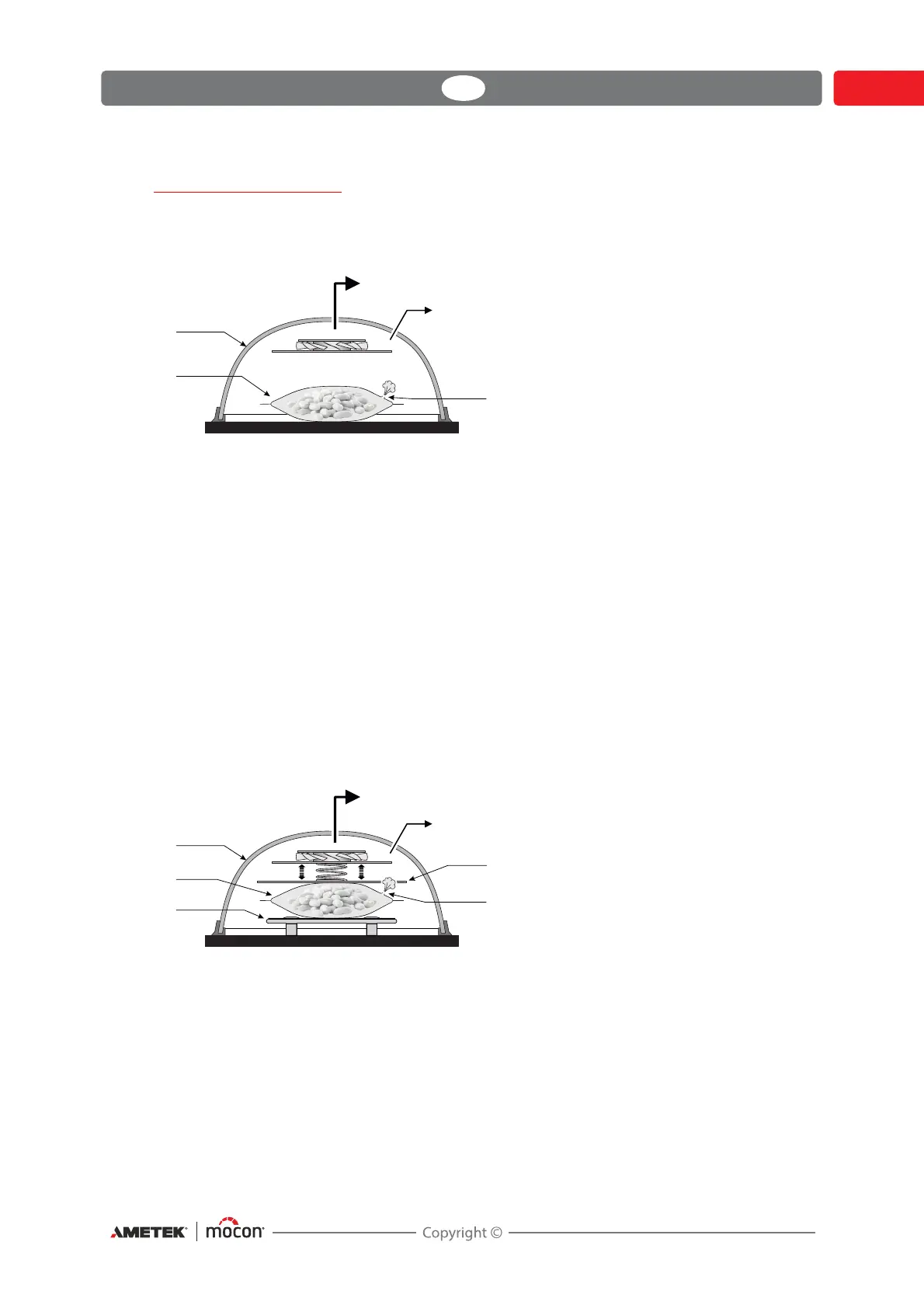

Without PackFix (Single Package or Multi Package)

1. The package is placed in the chamber and the measurement sequence starts when

the chamber is closed.

2. When vacuum builds up inside the chamber, the package will expand, thus creating a

positive pressure (Delta P) inside it and if there is a hole

in the package, CO

2

will leak

from inside the package and out into the chamber.

A sample pump sucks gas from the chamber through a sensor that detects the increased

CO

2

level and reports it as a leak.

3. Since this type of measurement is not made on the basis of a predetermined Delta P value,

the measurement result will be stated as the increase in the CO

2

level measured in the

chamber (in ppm/s).

4. When the measurement is complete, the vacuum is released from within the chamber and

the chamber

opens.

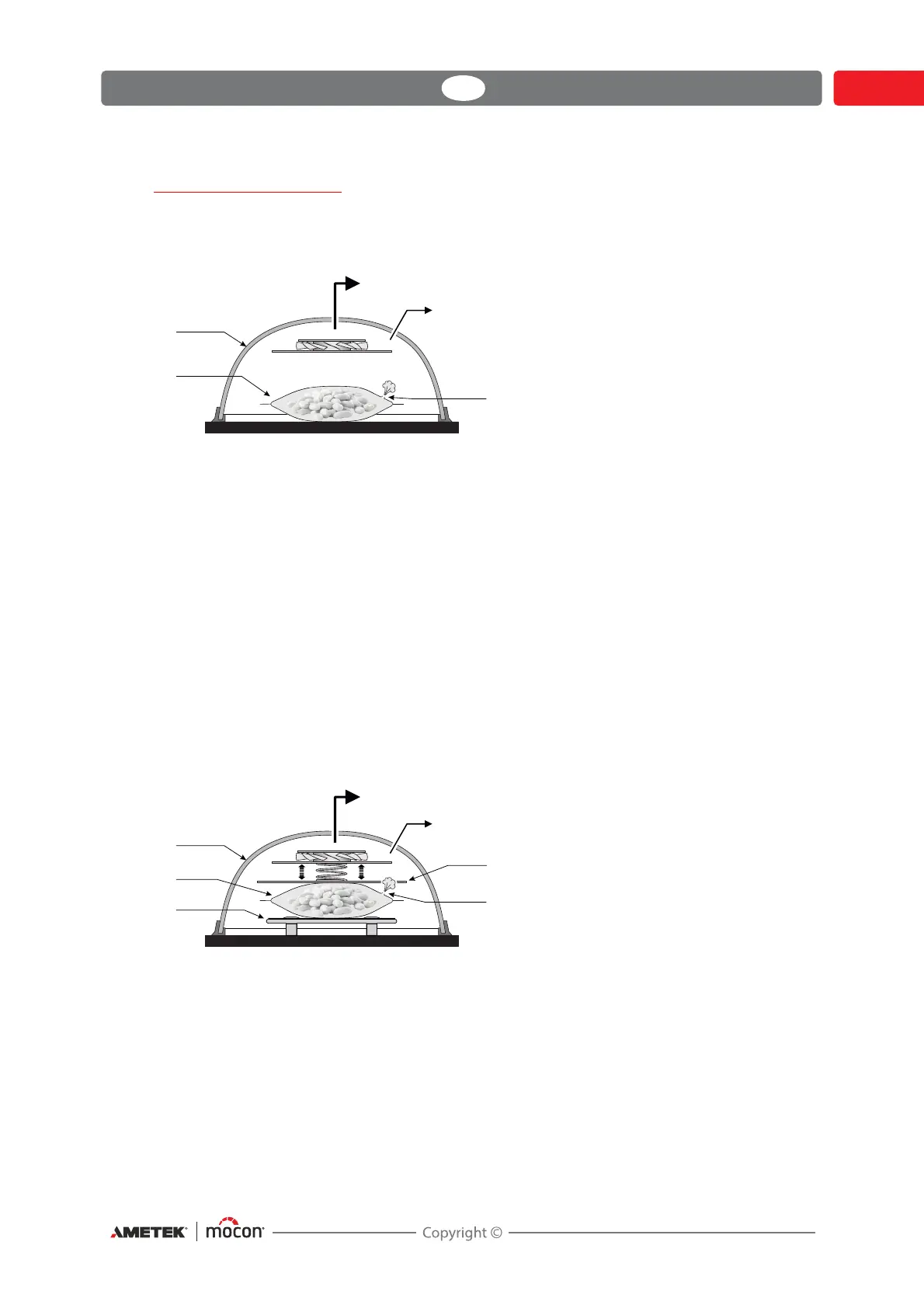

With PackFix (Single Package only)

1. The package is placed in the chamber and the measurement sequence starts when

the chamber is closed.

2. When vacuum builds up inside the chamber, the package expands and pushes against the

PackFix mechanism

. This creates a consistent positive pressure (Delta P) inside the

package and if there is a hole

in the package, CO

2

will leak from inside the package and

out into the measuring chamber.

A sample pump sucks gas from the chamber through a sensor that detects the increased

CO

2

level and reports it as a leak.

Loading...

Loading...