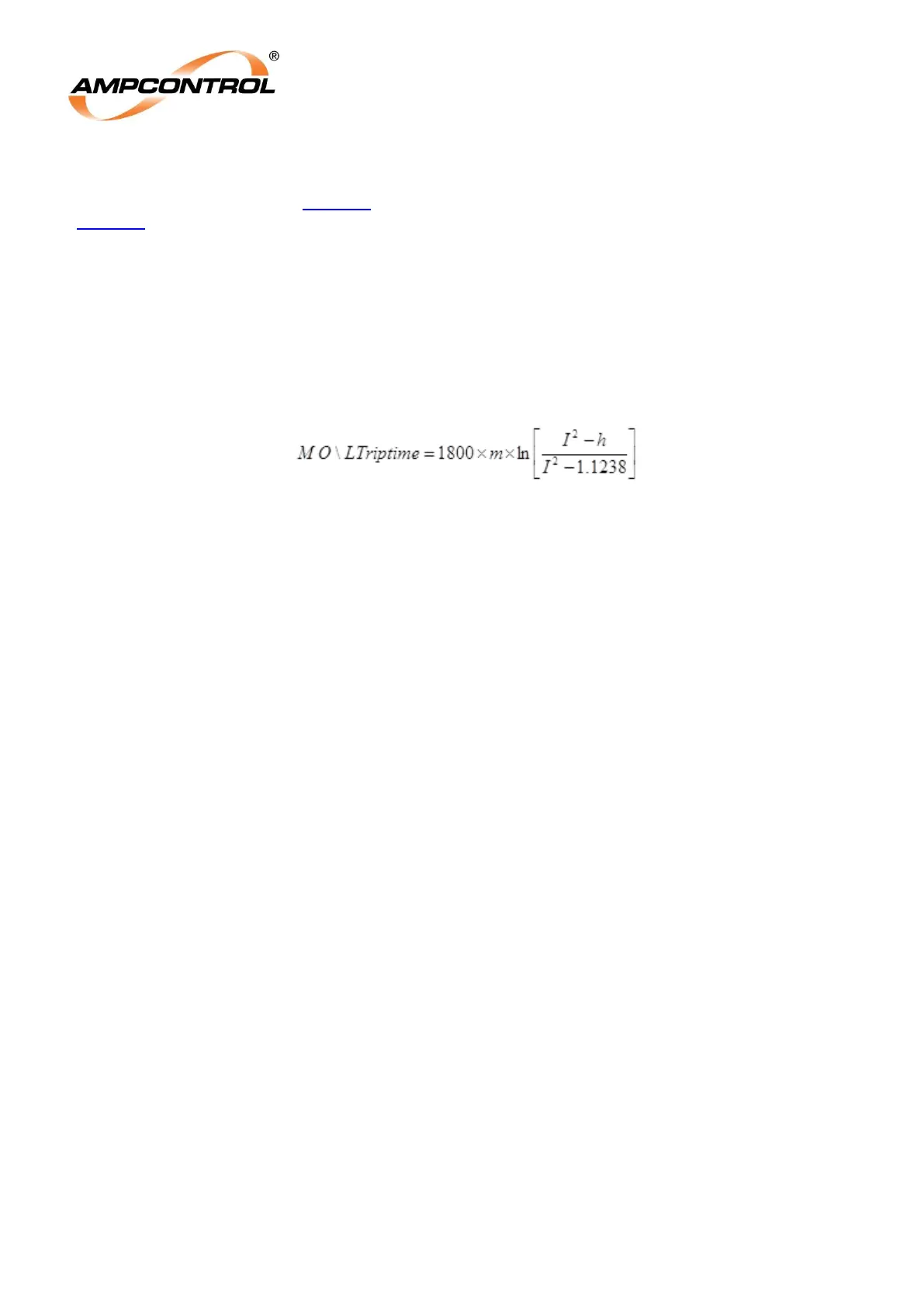

10.2.2 Motor Overload Characteristic

See “m-OL” Curves (Drawing IPDB019) and Motor Overload Functional Block Diagram (Drawing

IPDB035) in Appendix A – Drawings.

The current protection type “m-OL” is used when a motor overload characteristic is required. This

protection scheme uses a thermal model of the motor to determine the tripping characteristic. Thermal

modelling is based on a thermal time constant of 30 minutes (time multiplier setting of 1.0 times). The

time multiplier can reduce this value to a minimum thermal time constant of 1.5 minutes (time multiplier

setting of 0.05 times).

The three measured phase currents are squared and added together to provide the heating input into

the thermal model, which is described by:

Where:

m is the time multiplier

h is 0 for ‘cold motor’ and 1 for ‘hot motor’

Note that unlike Very Inverse current protection, Motor Overload protection does not have strictly

defined tripping times. The curves and function above describe the boundaries of the trip time, where:

The hot curve corresponds to the trip time after the motor has been running at the selected full

load current indefinitely (which results in a thermal accumulation of 89%), and

The cold curve corresponds to the trip time when the motor starts with zero accumulated thermal

energy.

The actual tripping times will normally be between these bounds, depending on the time the motor has

been running and the load, and hence the accumulated thermal energy in the motor.

The motor manufacturer’s data should be consulted to select the time multiplier appropriate for the

motor being protected. Typically, the capacity of a cold motor is given at six times its rated current. The

IPD trip curves can be used to select the time multiplier, which best suits the motors overload capacity.

While the main contactor is closed, the cooling output from the thermal model is calculated to achieve

the necessary time constants.

When the main contactor is open a “Cooling Multiplier” is used to modify the basic time constant. This

can be used to account for the reduced cooling capacity while the motor is not running (when

applicable, e.g. fan-cooled motors). This multiplier is selectable at 0.2, 0.3, 0.4, 0.5, 0.8, 1.0, 2, 5, 10,

20, and 50 times.

When 0.2 times is selected the motor off cooling rate is reduced to 20% of the motor running cooling

rate. A selection of 1.0 times sets the motor-off cooling rate equal to motor running cooling rate. This

selection is appropriate where cooling is maintained even when the motor is stopped, eg water cooled

motors.

Loading...

Loading...