13

5 Unpacking and installing the equipment

5.1 Type of Civil Engineering

The installation of a switchboard

requires a sufficiently flat and even

concrete structure. The dressing of

a top coat of cement using a rule

should eliminate any surface irregu-

larities greater than 2 mm per

metre.

A layout on iron supports for level-

ling off is ideal as they will also

serve as a guide for the adjustment

of the cement top coat.

The overall flatness of the support

surface should not show up any

deflection greater than 6 mm throu-

ghout the length of the switch-

board.

5.2 Unpacking the Functional Units

Proceed with unpacking the Functio-

nal Units only where they are to be

installed on site.

Tools required:

− Knife for road and rail

transport packaging

− Crowbar for air and sea

transport packaging

Use suitable protective gloves for

any handling operation.

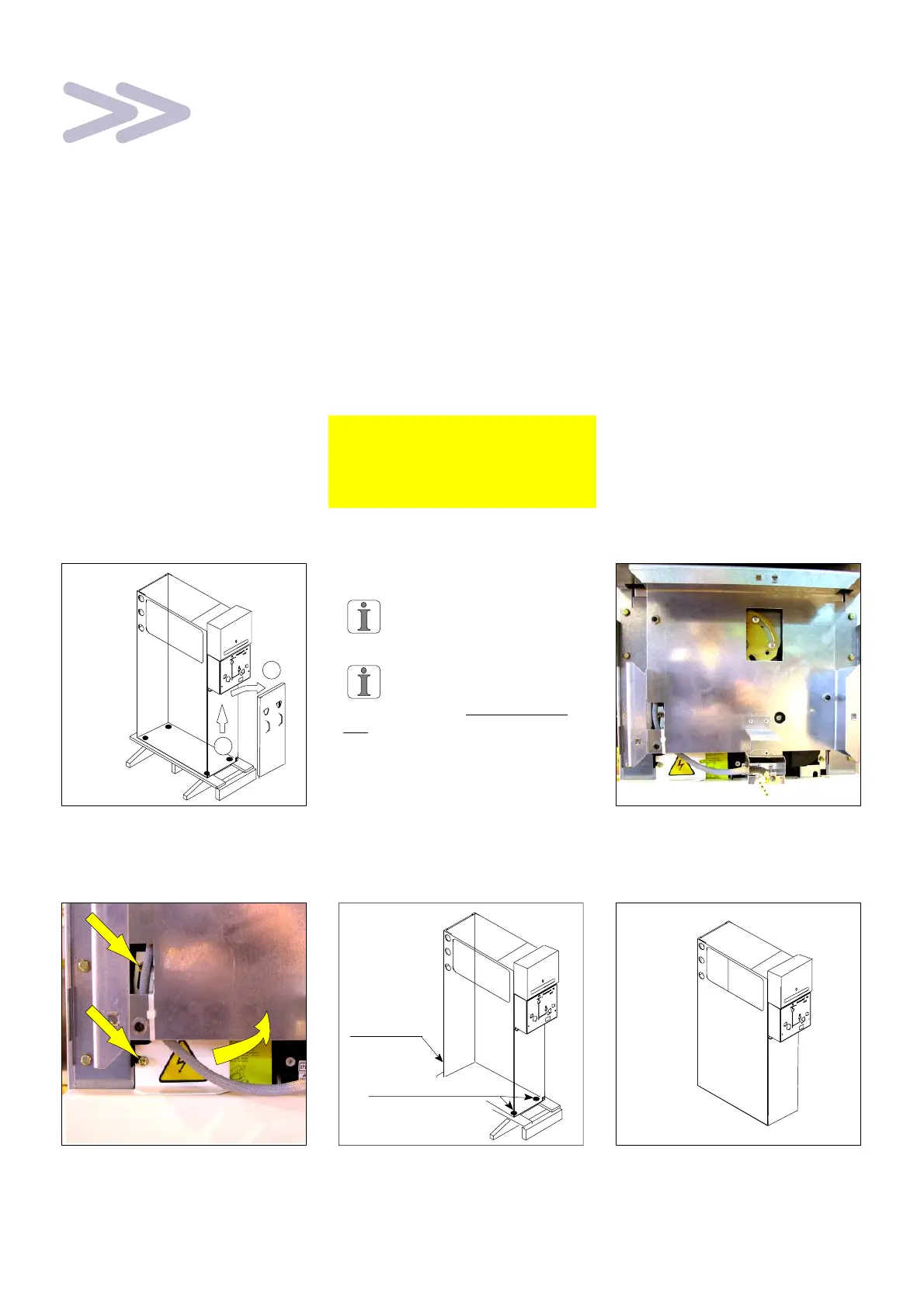

5.3 Handling the Functional Unit

F Remove the protective plastic

cover.

F Open the front panel:

1 − lift the panel

2 − pull the panel towards you.

1

2

F Special case of Functional Units

without an earthing switch.

Mark each panel in

accordance with the

corresponding Functional Unit.

For the PGB and PGC

Functional Units, remove

the wooden base without extrac-

ting the circuit breaker.

F Remove the mechanical control

hood (see the corresponding

manual § 2.5).

F Loosen the 2 CHC bolts.

F Pivot the lug towards the right.

F Remove the front panel.

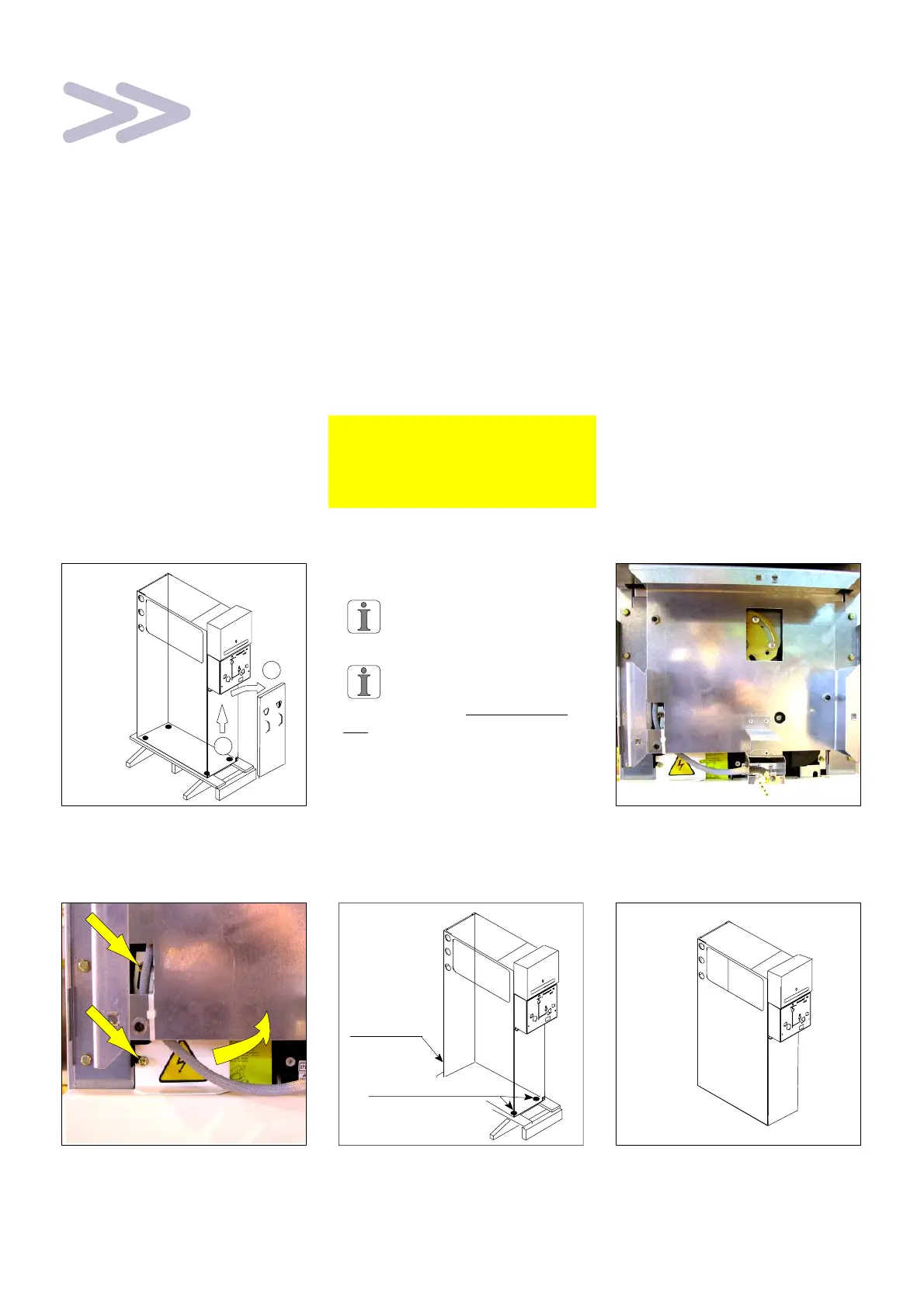

F Remove the 4 fixing screws

(16 mm spanner) from the

wooden base.

F Free the Functional Unit.

2 rear fixings

2 front fixings

F Place the Functional Unit on the

ground.

F Replace the front panel

Loading...

Loading...