45

17.4 Checking HV connections (busbars, cables, etc.)

F During the initial AREVA

maintenance operation the

torque levels of all HV

connector points must be

systematically verified.

F This test is certified by the

application of a small label –

stuck onto the ID plate.

F Then, a simple visual inspection

is required.

Specific case – switchboards assembled by AREVA

A label stuck onto the ID plate is

used to certify the torque of the

busbar (See § 17.4).

It is not necessary that the busbar

be checked again.

On the other hand, the other

connector points should still be

checked.

Specific case – request for systematic verification of torque levels (vibration, etc.)

A systematic check of all High Vol-

tage connections tightening points

may be requested by the customer.

Every 3 operations, it is there-

fore necessary to replace all

of the threaded fasteners .

17.5 Greasing of the contact surfaces

Intervention Duration Busbar Cables Load Break Switch Earthing switch

Normal 1 h 00 de−energized de−energized open closed

Possible 1 h 00 energized de−energized open closed

Apply the General Safety Instruc-

tions for Electrical Applications and

the particular rules for the network

concerned for locking out procedu-

res.

Greases: (See §2.6)

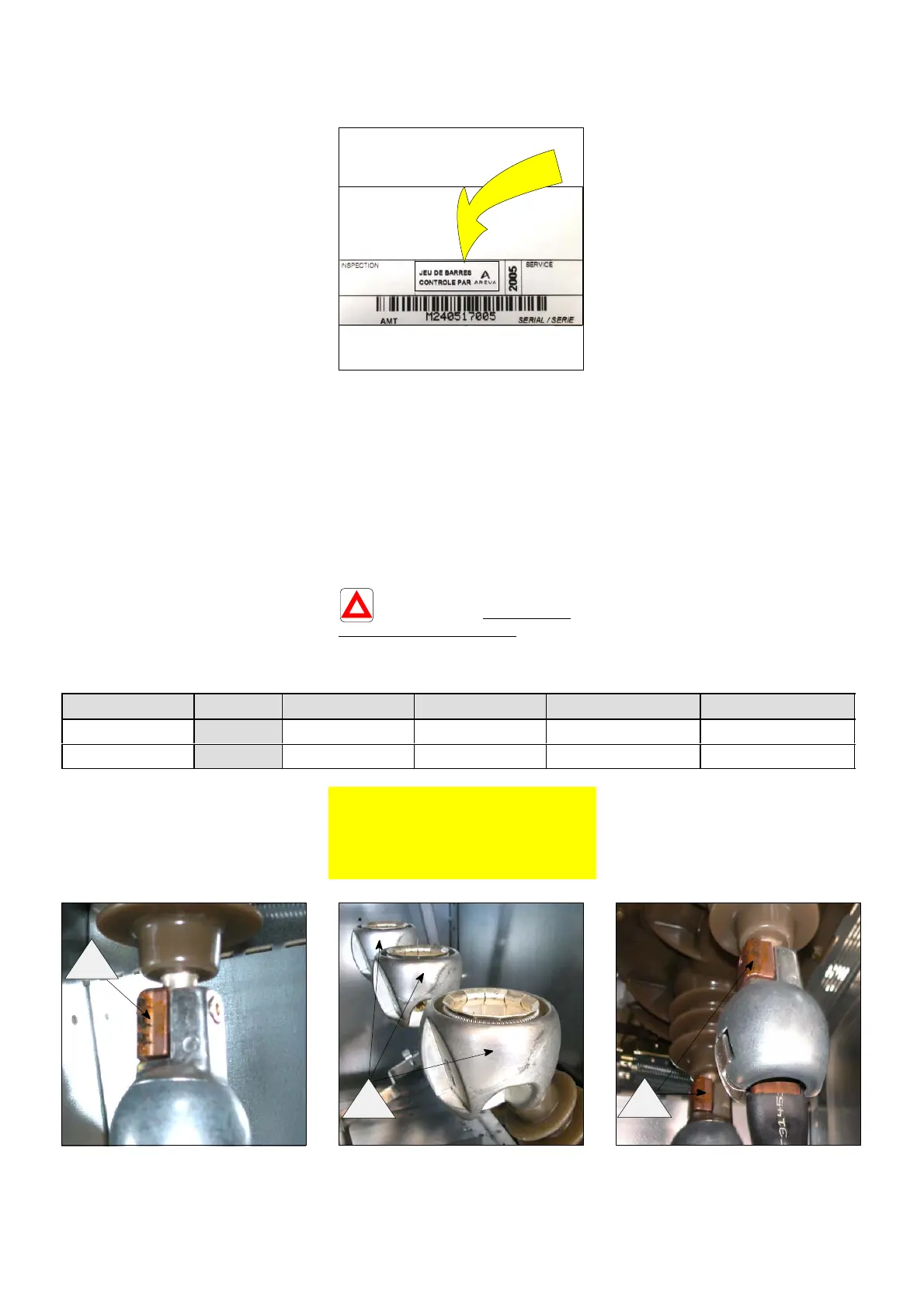

F Clean and apply a film of

grease to the plugging−in studs

on the earthing switch.

22

F Clean and apply a film of

grease to the lower cups on the

PF−PFA, for contact with the

earthing switch.

22

F Clean and apply a film of

grease to the contact plates on

the downstream earthing switch

for a PGC.

22

Loading...

Loading...