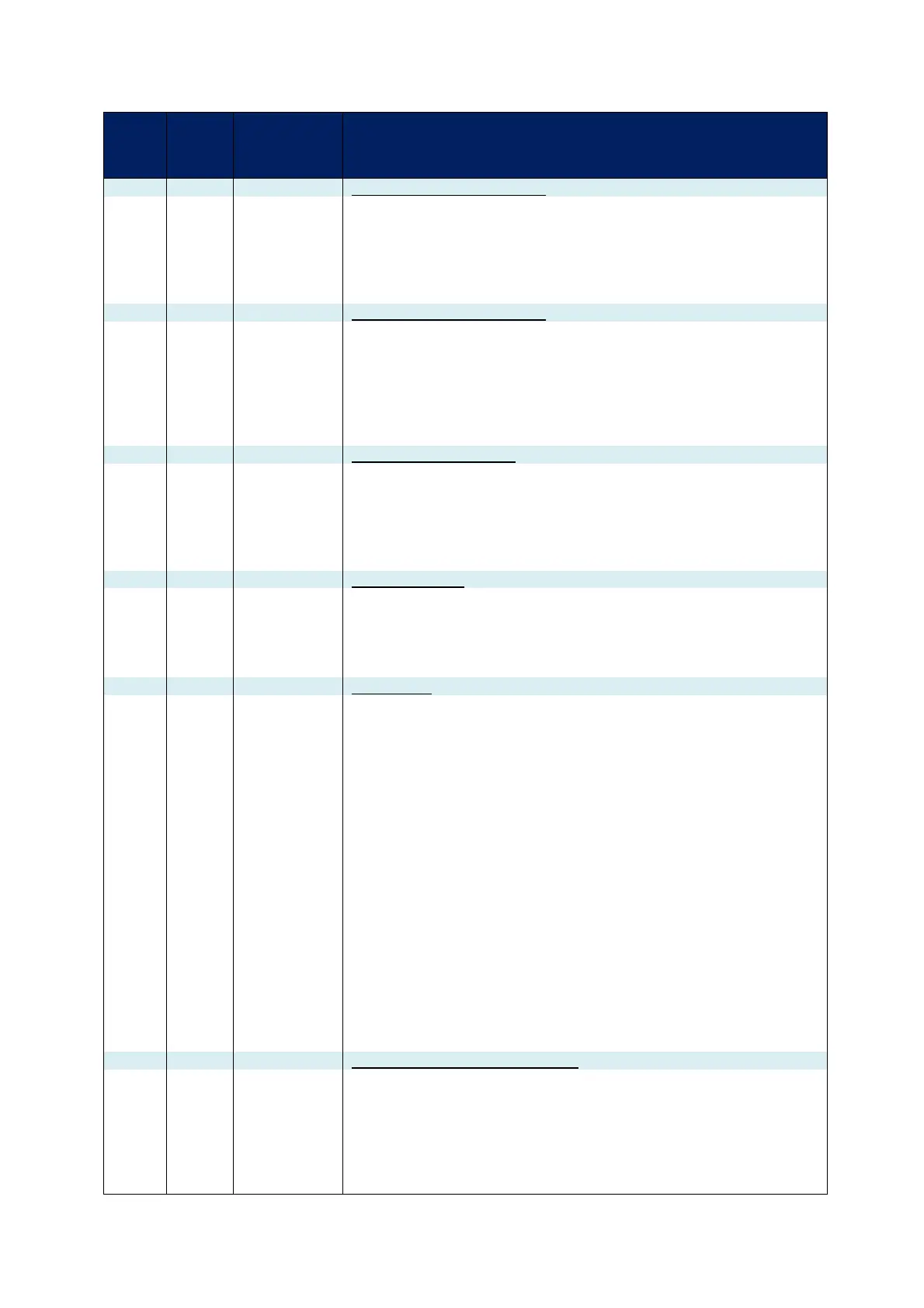

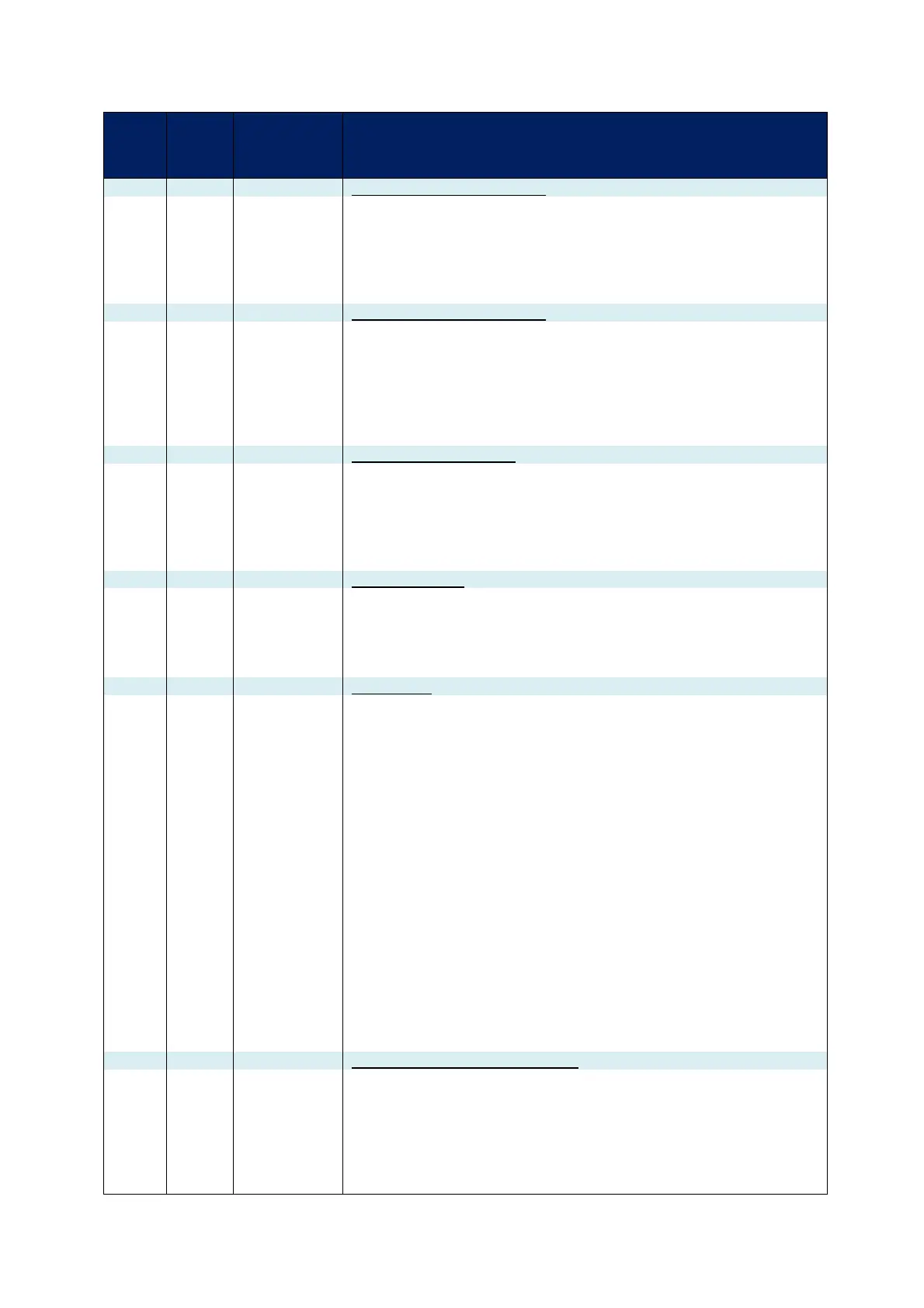

2 Expansion Options

Page 18 Mk8 MM Expansion Features Installation and Set-Up Guide 04.09.2016

Exp

Option

Default Range Description

87 0 Pressure Tolerance Before Fault

This is the maximum variation from the commissioned draught air pressure.

If the pressure is at this maximum variation or higher for 2 minutes, then an

alarm/warning is generated, see expansion option 88.

0 Disabled

1 – 500 0.1 – 50.0 mbar or 0.1 – 50.0 ”WG (see parameter 43)

88 0 Action on Pressure Sensor Fault

For setting 0, an alarm will occur and the burner will stop firing. For setting

1, a warning will occur and the burner will continue firing, with the draught

servomotor will move to the commissioned angle throughout the firing

curve, without any draught control compensation.

0 Draught pressure sensor fault generates alarm

1 Draught pressure sensor fault generates warning

89 15 Pressure Sensor Filter Time

This is the time period over which the draught air pressure sensor readings

are filtered over time. If there is excess fluctuation in the pressure readings,

increase the filter time. To improve the system’s response to changes in

pressure, decrease the filter time.

1 – 60 Seconds

90 200 Proportional Band

The proportional band is an offset from the commissioned draught air

pressure, where the PI control will make corrections to maintain the

commissioned air pressure.

1 – 10000 2.00 – 100.00 mbar or 2.00 – 100.00 ”WG (see parameter 43)

91 5 Integral Time

For a slower response to the changes in draught air pressure, increase the

integral time. For a quicker response, decrease the integral time.

1 – 1000 Seconds

92 - Unused

93 - Unused

94 - Unused

95 - Unused

96 - Unused

97 - Unused

98 - Unused

99 - Unused

100 0 Sequencing/DTI or Modbus Function

To enable direct Modbus, the Modbus expansion feature must be unlocked.

If direct Modbus is enabled, then option 16 must be set to 0, as Intelligent

Boiler Sequencing cannot be used with direct Modbus. Please see section

4.2 for the available Modbus addresses.

0 MM/DTI Sequencing

1 Modbus

Loading...

Loading...