Lockout/Tagout

Hazardous energy (lockout/tagout) must be controlled in machine maintenance and servicing situations in which the

unexpected energization, start up, or release of stored energy could cause injury. Refer to OSHA 29CFR 1910.147, ANSI

2244.1, ISO 14118 , ISO 12100 or other relevant standards to ensure that bypassing a safeguarding device does not

conflict with the requirements that are contained within the standards.

WARNING: Limit Use of Bypass Function

The Bypass function is not intended for production purposes; it is to be used only for

temporary or intermittent actions, such as to clear the defined area of a safety light screen if

material becomes "stuck". When Bypass is used, it is the user's responsibility to install and use it

according to relevant standards (such as ANSI NFPA79 or IEC/EN60204-1).

Safe Working Procedures and Training

Safe work procedures provide the means for individuals to control exposure to hazards through the use of written

procedures for specific tasks and the associated hazards. The user must also address the possibility that an individual

could bypass the safeguarding device and then either fail to reinstate the safeguarding or fail to notify other personnel of

the bypassed condition of the safeguarding device; both cases could result in an unsafe condition. One possible method to

prevent this is to develop a safe work procedure and ensure personnel are trained and correctly follow the procedure.

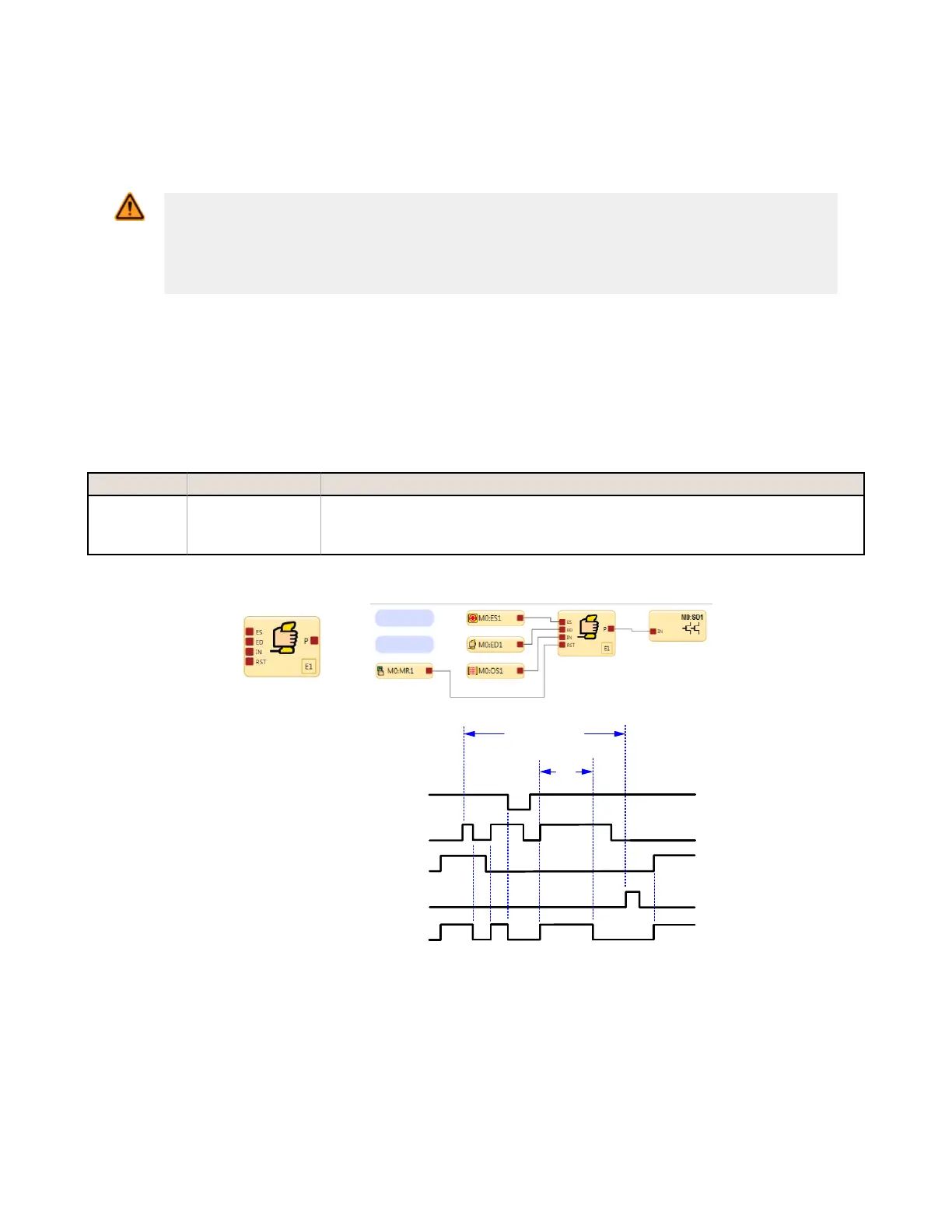

Enabling Device Block

Default Nodes

Additional Nodes Notes

ED

IN

RST

ES

JOG

An Enabling Device Block must be connected directly to an Output Block. This method assures that the

final control of the outputs is given to the operator holding the Enabling Device. Use the ES node for

safety signals that should not be bypassed by the ED node. If no other inputs of the function block are

configured, using an Enabling Device function block is not required.

t

limit

M0:SO1

M0:ES1

M0:ED1

M0:OS1

M0:MR1

Enable Mode

ES1 & ED1 have On/Off Control

Enabling Device

Function Block

Figure 17. Timing Diagram—Enabling Device, Simple Configuration

XS/SC26-2 Safety Controller

27

Loading...

Loading...