force a sequenced reset routine, which can be used to reduce or eliminate pass-through hazards in perimeter guarding

applications (see Safety Input Device Properties on page 69).

If the controlling inputs to a Latch Reset Block or a Safety Output Block are not in the Run state, the reset for that block

will be ignored.

Reset Signal Requirements

Reset Input devices can be configured for monitored or non-monitored operation, as follows:

Monitored reset: Requires the reset signal to transition from low (0 V dc) to high (24 V dc) and then back to low. The

high state duration must be 0.5 to 2 seconds. This is called a trailing edge event.

Non-monitored reset: Requires only that the reset signal transitions from low (0 V dc) to high (24 V dc) and stays high

for at least 0.3 seconds. After the reset, the reset signal can be either high or low. This is called a leading-edge event.

Muting Block

Default Nodes

Additional Nodes Notes

IN

MP1

MP2

ME

BP

Muting Sensor Pair input blocks must be connected directly to the Muting function block.

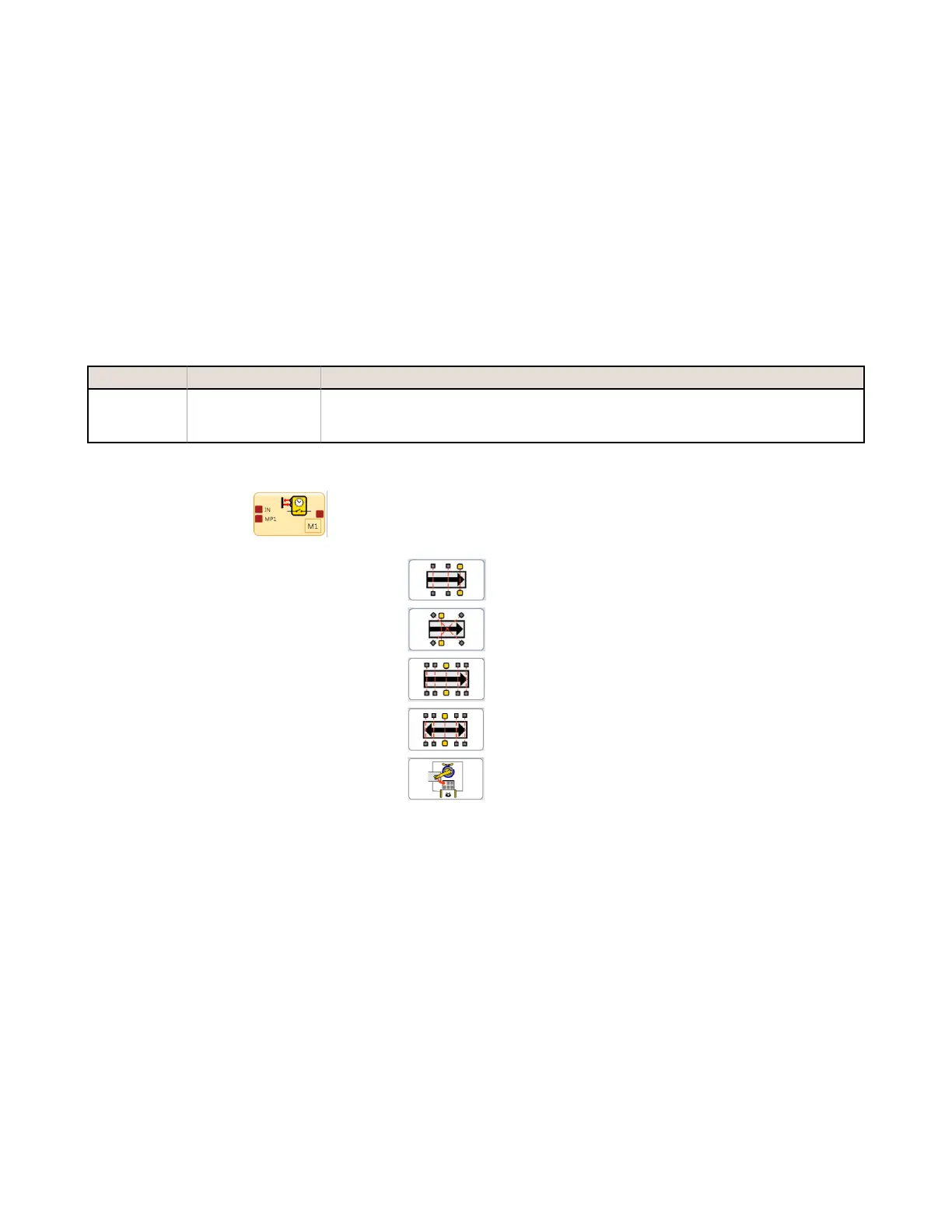

One Way - 1 Mute Sensor Pair

Two Way - 1 Mute Sensor Pair

One Way - 2 Mute Sensor Pair

Two Way - 2 Mute Sensor Pair

Two Way - 1 Mute Sensor Pair

Mute Function Block

There are five Mute Function types listed below. The following timing diagrams show the

function detail and sensor/safeguarding state change order for each mute function type.

Figure 24. Muting Block—Function Types

XS/SC26-2 Safety Controller

32

Loading...

Loading...