29

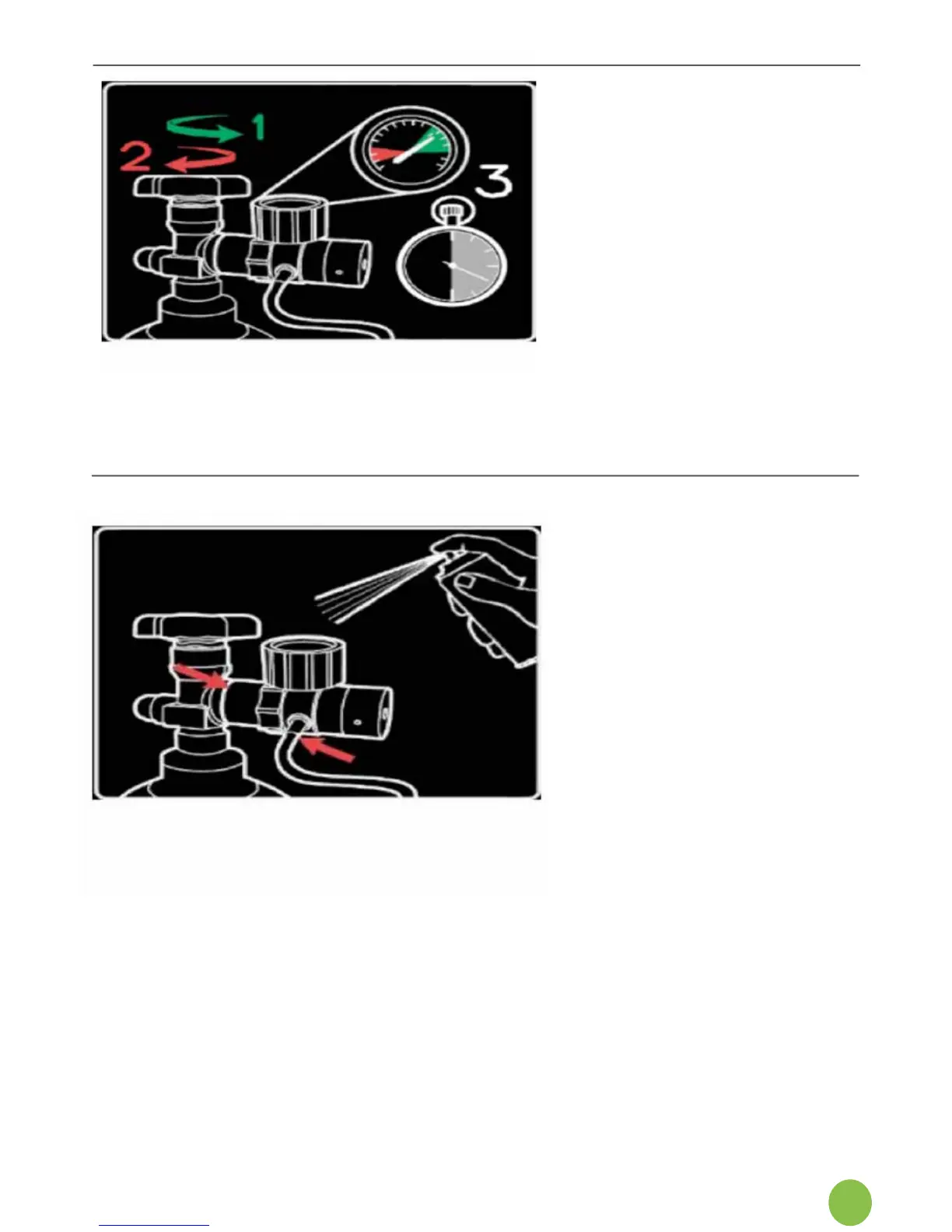

11. To test that each supply line

iscorrectlysetup,performa

high-pressure leak test as

follows:

a. Withthevalveopen,note

where the pressure gauge

needle is pointing.

b. Closethecylindervalveand

observethegaugefor30

seconds.

c. Iftheneedleremainsconstant,

thelineiscorrectlysetup;

press the check mark.

d. If the needle shows a drop in

pressure,aleakexists;press

the X.

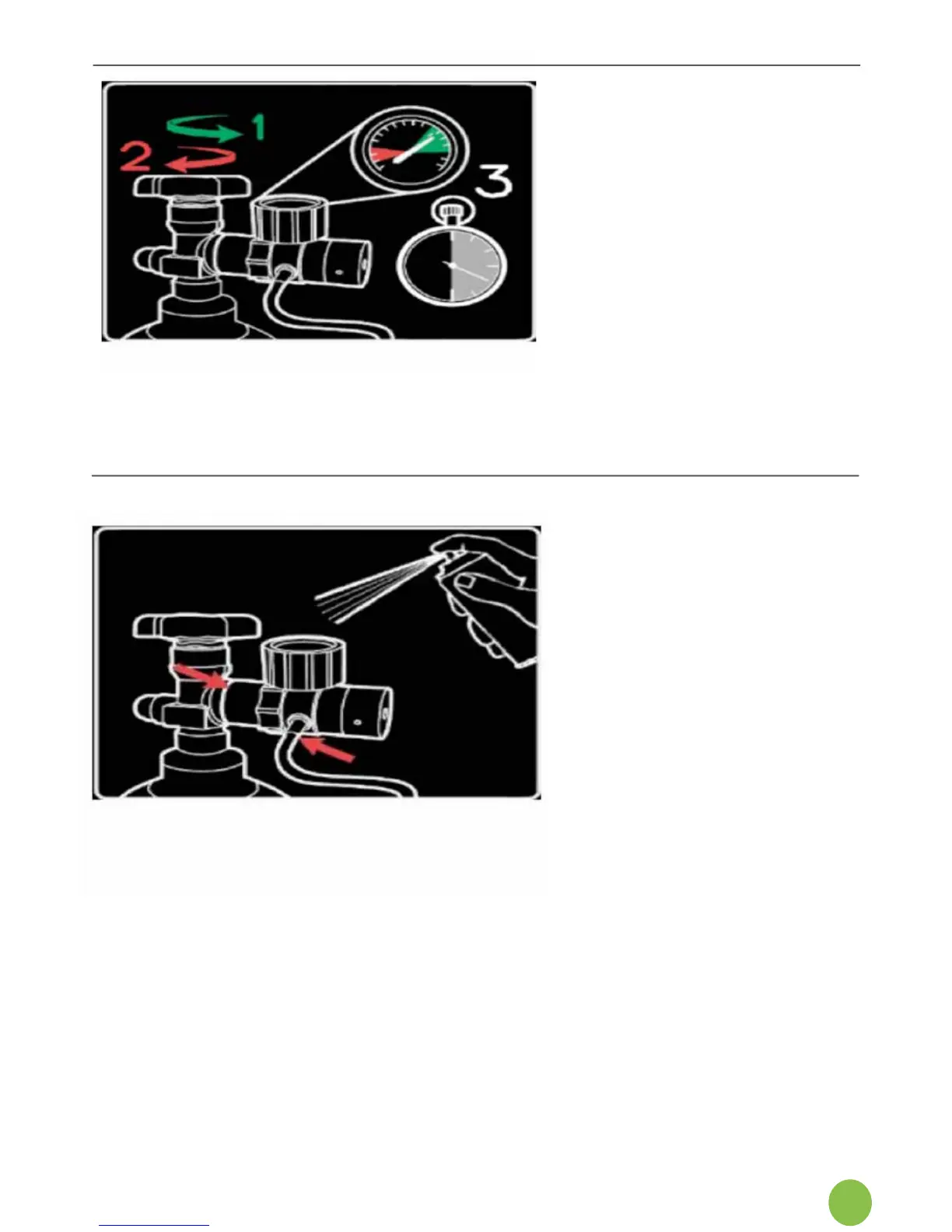

12. If leak detected: If the line

has failed the high pressure

test,theninvestigatethe

connectionsforanyleaks:

a. Withpressureinthelines,use

liquid leak detector around the

regulator seal and hose

connections and look for

bubblingintheuid.

b. Purge the hose line pressure

beforeremovingand

reattaching the regulator to the

cylinder. The pressure gauge

should always read 0 bar

before disconnecting the

regulator from the cylinder.

c. Rule out leak in the

external regulator and supply

line:Ensuretheregulator

supply line connector is

correctly locked to the

regulatoroutlet,andthe

collar of the connector on

the free-end of the line is

pulledback(sealed).

(seestep7).Openthe

cylinder to pressurize

only the regulator and

thesupplyline(freeendnot

attachedtomonitor).Close

cylindervalveandobserve

needle for 30 seconds.

d. Purgethehoselinepressure;

connect the free end of the

hose back onto the inlet port

on the monitor.

Loading...

Loading...