PL-6000DC/DCX Two-Post Parking Lift 67 P/N 5900273 — Rev. A6 —July 2024

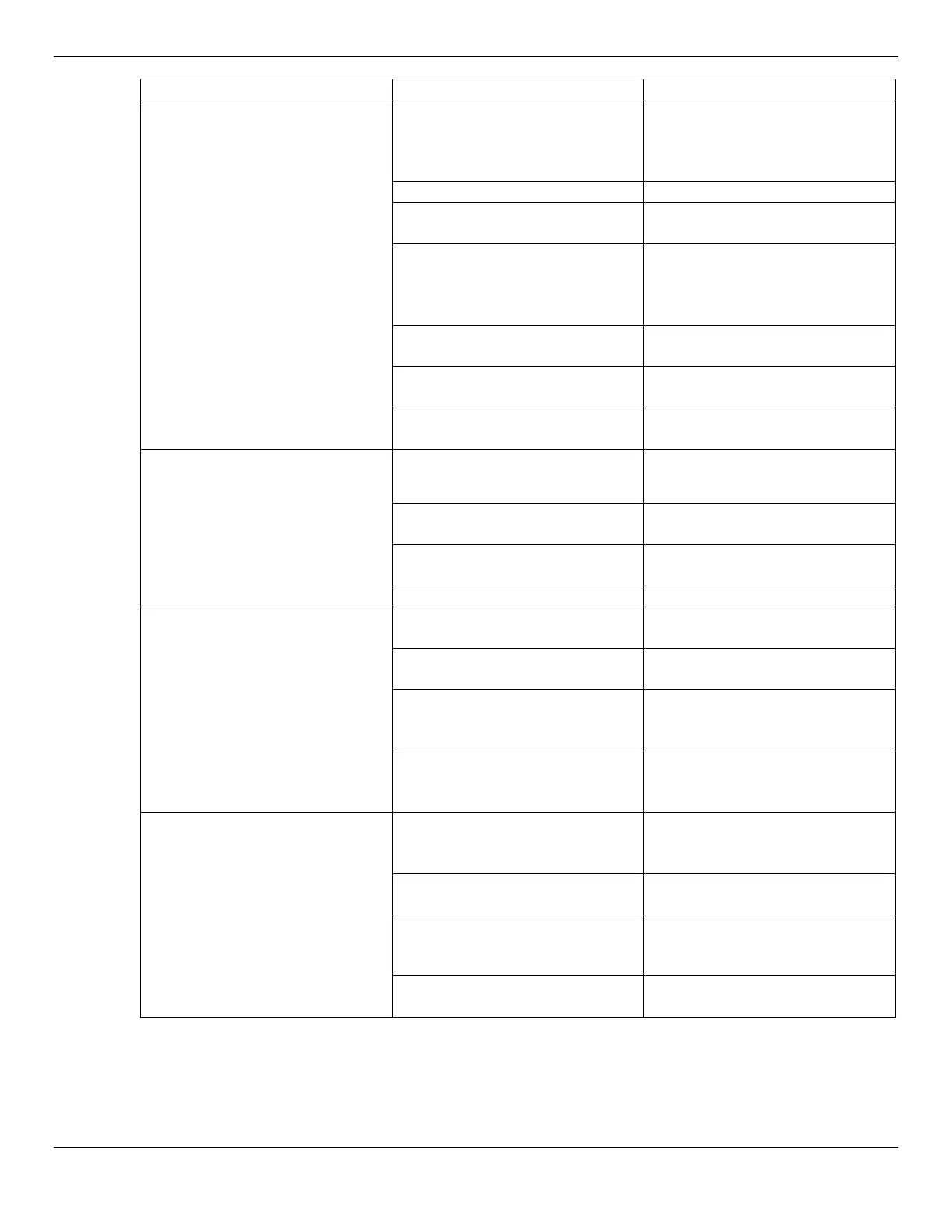

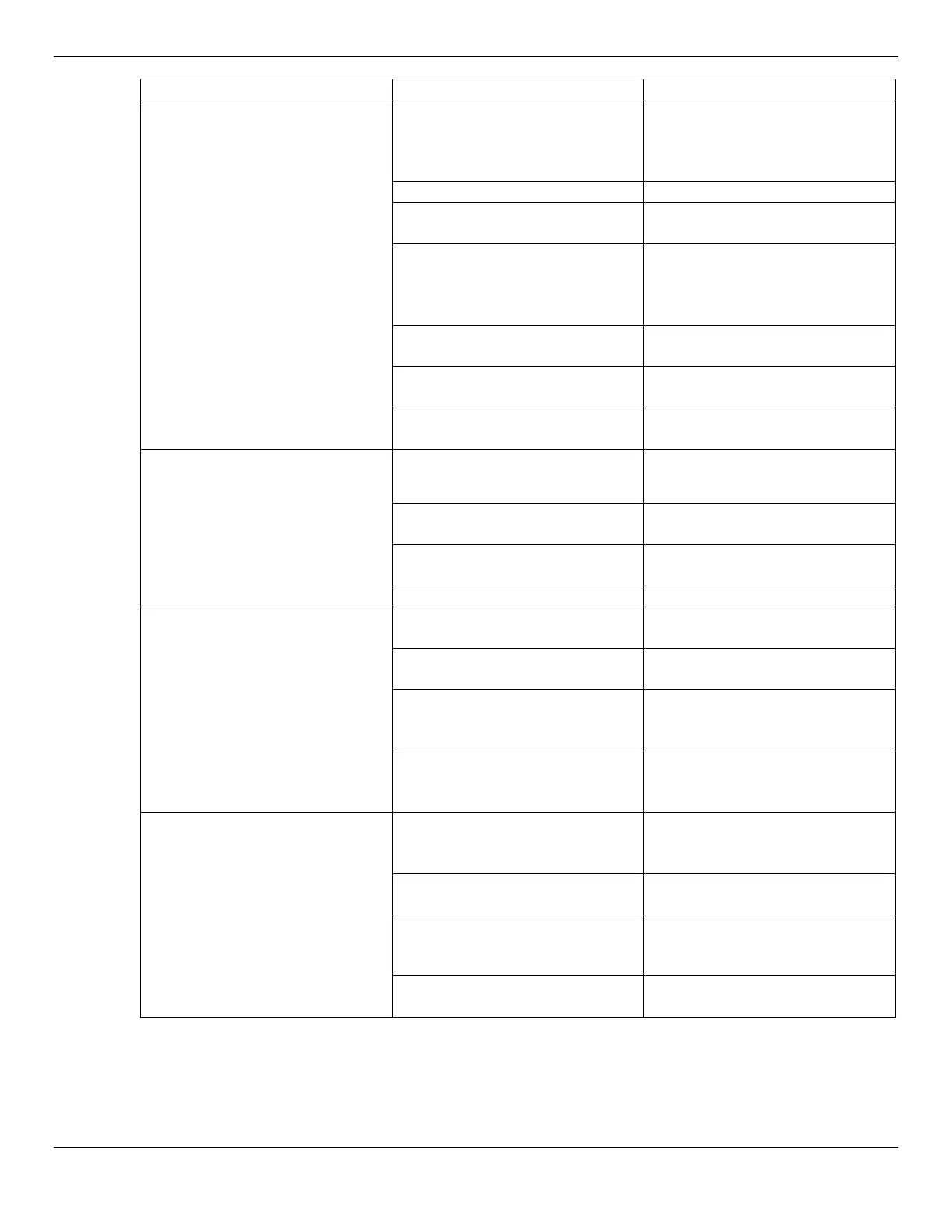

Insufficient thrust or low speed.

Oversize/undersize fit clearance

between bore and Cylinder

Rod, broken or incorrect seals.

Repair/replace parts with

correct size and accuracy.

Seals to be reassembled,

Severe leaking of the Cylinder.

Straighten Rod or replace

Cylinder.

resulting in loss of concentricity

or excessive friction on one

reassemble.

Damaged Cylinder Bore results

in blocked Rod

Hone to repair Cylinder bore.

Damaged Cylinder Bore results

in blocked Rod

Hone to repair Cylinder bore.

Contaminated Hydraulic Fluid

results in block Cylinder Rod.

Clean Hydraulic Circuit and

replace Hydraulic Oil.

Insufficient thrust or low speed.

(Continued)

Hydraulic Oil Temperature too

high causing Seals to leak.

Search for cause of excessive

temperature.

Insufficient Hydraulic Oil in the

Reservoir.

Fill Hydraulic Fluid Reservoir.

Excessive Oil pressure in return

line.

Increase diameter of return line,

reduce back pressure valve.

Pressure Relief Valve failure.

Replace Pressure Relief Valve.

Galling, scratches, or damaged

seals.

Seal incorrectly installed.

Replace Seal and install in the

correct direction.

Longitudinal scratches or

grooves between moving parts

inside the Cylinder body.

Repair or replace the Cylinder

parts or the complete Cylinder.

Vibration of inlet and outlet

Hydraulic Oil pipes result in

loosening of connection points.

Tighten the inlet and outlet

pipes or change connection

Air in the Hydraulic System.

Eliminate leaks and bleed the

system of air by raising and

lowering the Lift several times.

Clearances between relative

moving/sliding parts is too tight.

Disassemble and re-assemble

with proper clearances.

Excessive friction and/or lack of

lubrication on sliding seal

Deformed or damaged Guiding

Support Ring.

Support Ring to be repaired or

replaced.

If you continue to have issues with your Lift, take it out of service, then contact your dealer, go to

bendpak.com/support, email support@bendpak.com, or call (800) 253-2363, follow the

prompts to reach support.

Loading...

Loading...