A

THE

ENGINE

•

,

...

- ....

~-

•

49Qf'

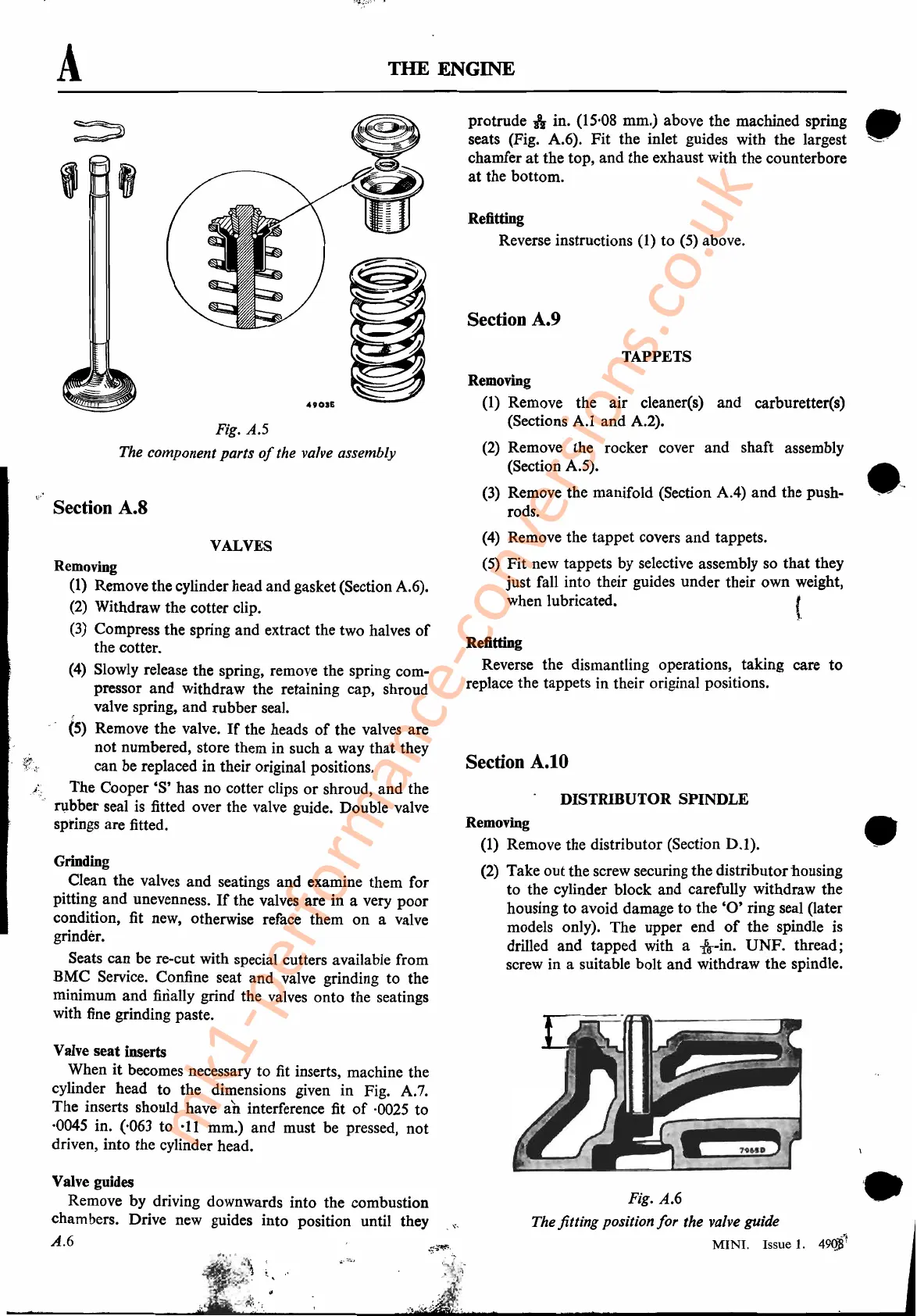

Fig. A.6

The fitting position

for

the valve guide

MINI.

Issue

1.

Removing

(1)

Remove the distributor (Section

0.1).

(2)

Take outthe screw securing the distributorhousing

to the cylinder block and carefully withdraw the

housing to avoid damage to the

'0'

ring seal (later

models only). The upper end

of

the spindle

is

drilled and tapped with a

-&--in.

UNF.

thread;

screw in a suitable bolt and withdraw the spindle.

DISTRIBUTOR SPINDLE

TAPPETS

Refitting

Reverse instructions (1) to (5) above.

Removing

(1) Remove the air cleaner(s) and carburetter(s)

(Sections

A.l

and A.2).

(2)

Remove the rocker cover and shaft assembly

(Section A.5).

(3)

Remove the manifold (Section

AA)

and the push-

rods.

(4)

Remove the tappet covers and tappets.

(5)

Fit new tappets by selective assembly so that they

just fall into their guides under their own weight,

when lubricated.

{,

Refitting

Reverse the dismantling operations, taking care to

replace the tappets in their original positions.

protrude

If

in. (15'08 mm.) above the machined spring •

seats (Fig. A.6). Fit the inlet guides with the largest ',-,'

chamfer

at

the top, and the exhaust with the counterbore

at

the bottom.

Section A.9

Section

A.tO

4901£

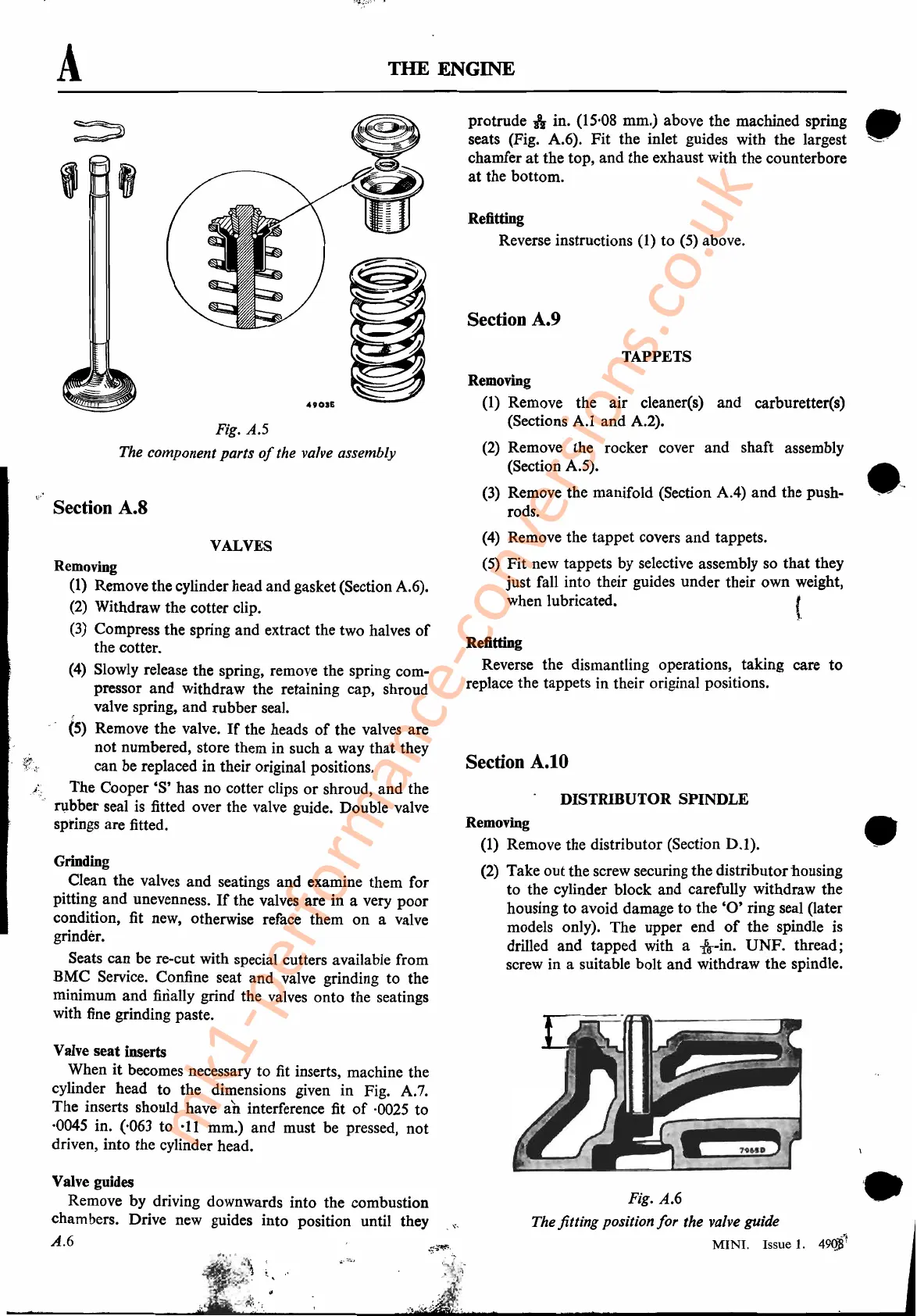

Fig. A.5

The component parts

of

the valve assembly

Removing

(1)

Remove the cylinder head and gasket (Section A.6).

(2)

Withdraw the cotter clip.

(3)

Compress the spring and extract the two halves

of

the cotter.

e

4)

Slowly release the spring, remove the spring com-

pressor

and

withdraw the retaining cap, shroud

, valve spring, and rubber seal.

(5)

Remove the valve.

If

the heads

of

the valves are

not numbered, store them in such a way that they

can be replaced in their original positions.

The

Cooper'S'

has no cotter clips

or

shroud, and the

I1lbber seal

is

fitted over the valve guide. Double valve

springs are fitted.

Grinding

Clean the valves and seatings and examine them for

pitting and unevenness.

If

the valves are in a very poor

condition, fit new, otherwise reface them

on

a valve

grinder.

Seats can be re-cut with special cutters available from

BMC Service. Confine seat and valve grinding to the

minimum and finally grind the valves onto the seatings

with fine grinding paste.

VALVES

Valve

seat

inserts

When

it

becomes necessary to fit inserts, machine the

cylinder head to the dimensions given in Fig. A.

7.

The inserts should have

an

interference fit

of

·0025 to

·0045 in. (,063 to

·11

mm.) and must be pressed, not

driven, into the cylinder head.

Valve guides

Remove by driving downwards into the combustion

chambers. Drive new guides into position until they

A.6

Section A.8

mk1-performance-conversions.co.uk

Loading...

Loading...