A

THE

ENGINE

Oil filler cap

(1) Remove the combined oil filler cap

and

breather

filter and fit a replacement

at

the recommended

servicing period.

Breather control valve

(2) Remove the retaining clip (1) and dismantle the

valve.

(3) Clean all metal parts with solvent (trichlorethylene,

fuel, etc.).

If

deposits are difficult

to

remove,

immerse in· boiling water before applying the

solvent.

Do

not

use

an

abrasive.

(4) Clean the diaphragm (3) with detergent

or

methy-

lated spirit.

(5) Replace components showing signs

of

wear

or

damage.

(6) Reassemble the valve, ensuring the metering

needle (4)

is

in the cruciform guides (6)

and

the

diaphragm is

seat~d

correctly.

NOTE.-

The 1st type valve assembly (without

the cruciform guides) is serviced as an assembly.

Section A.28

•

I

2

12

13

3

14

-4

5

6

•

•

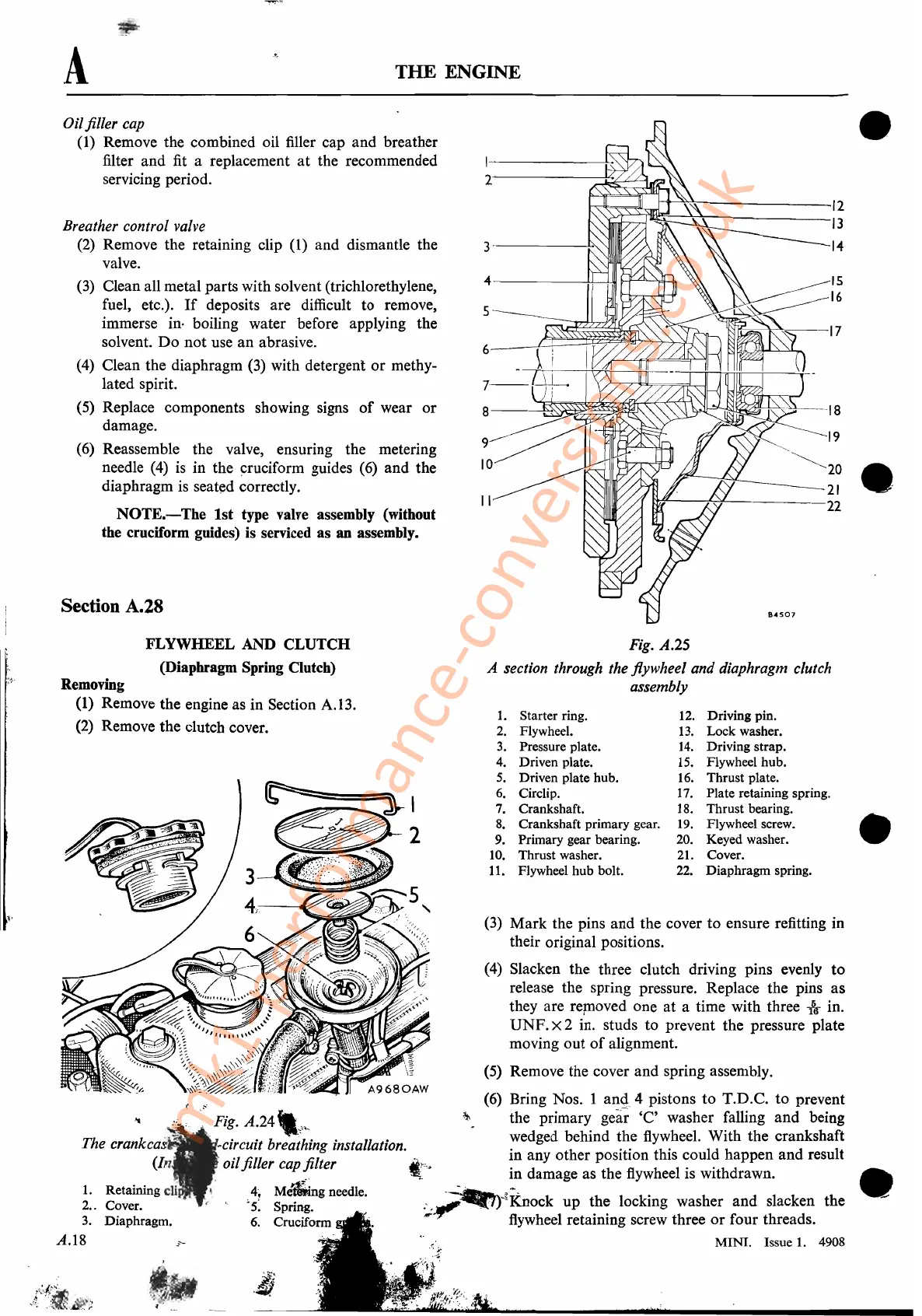

12. Driving pin.

13. Lock washer.

14.

Driving strap.

15. Flywheel hub.

16. Thrust plate.

17. Plate retaining spring.

18. Thrust bearing.

19.

Flywheel screw.

20. Keyed washer.

21. Cover.

22. Diaphragm spring.

1.

Starter ring.

2.

Flywheel.

3.

Pressure plate.

4. Driven plate.

5.

Driven plate hub.

6.

Circ1ip.

7. Crankshaft.

8.

Crankshaft primary gear.

9. Primary gear bearing.

10. Thrust washer.

11. Flywheel hub bolt.

Fig.

A.25

A section through the flywheel and diaphragm clutch

assembly

FLYWHEEL AND

CLUTCH

(Diaphragm Spring Clutch)

Removing

(1) Remove the engine as in Section A.I3.

(2) Remove the clutch cover.

(3)

Mark

the pins

and

the cover

to

ensure refitting in

their original positions.

(4) Slacken the three clutch driving pins evenly

to

release the spring pressure. Replace the pins

as

they are reploved one at a time with three

fa

in.

UNF.

X 2 in. studs

to

prevent the pressure plate

moving

out

of

alignment.

(5) Remove the cover and spring assembly.

t.--

(6) Bring Nos. I

am!4

pistons

to

T.D.C.

to

prevent

"

:'

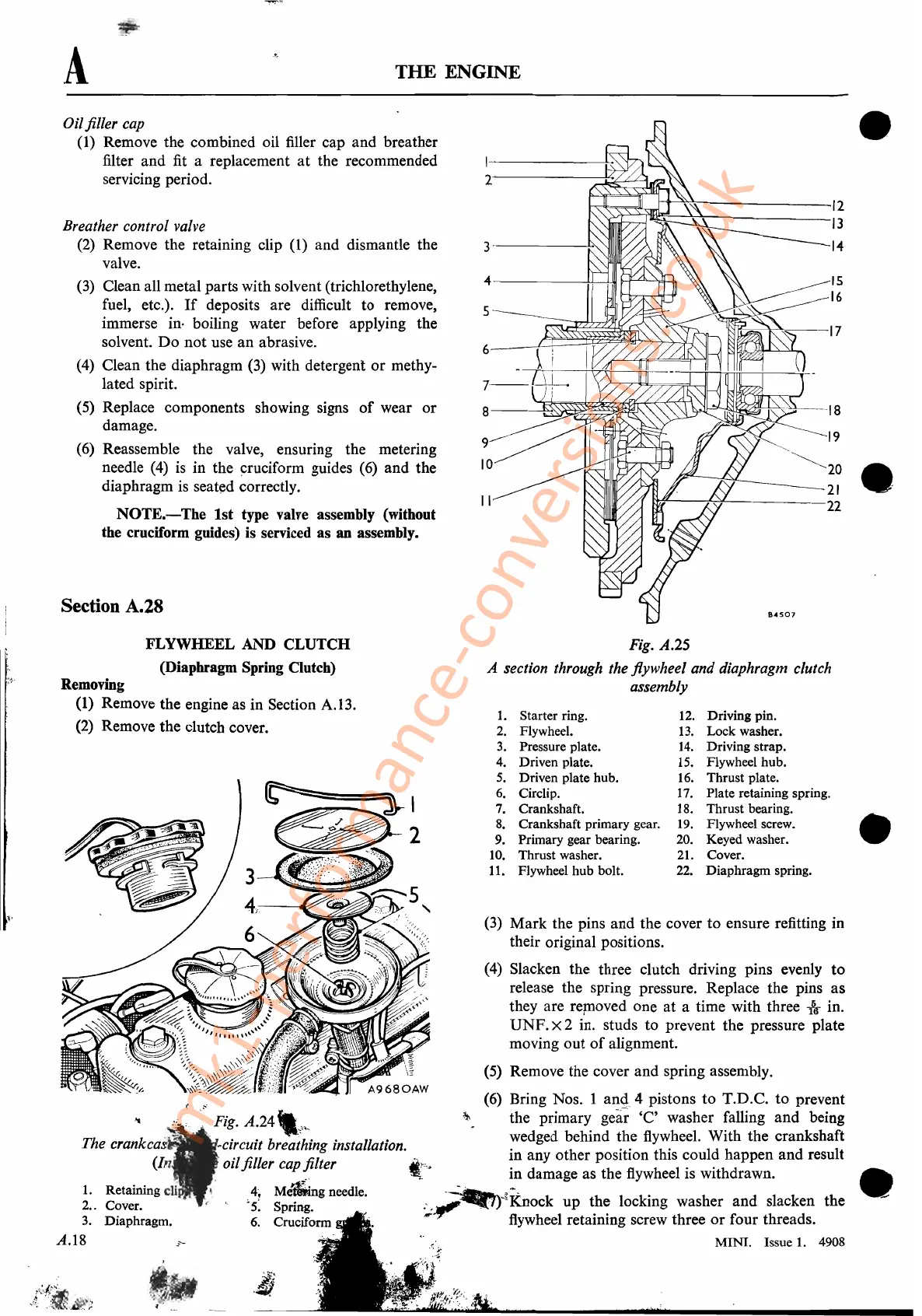

Fig. A.24

'"~,_

'!,t,

the

primar~

gear

'C'

washer

~alling

and

being

T'he

k

1-

, . 't b th' .

Il'

.

w.e.

dged behmd the flywheel. WIth the crankshaft

.l. J cran cas

-CzrCUl

rea

mg msta

atzon.

. . . .

(

T

'1

fill filt . In any other posItIOn

thIS

could happen

and

result

~n

01 er

cap

er

M.)-.~.

I . . d

,

_.

~

m damage as the flywhee

IS

WIth

rawn. •

1.

Retaining cli

~

4,

Memmg

needle.

'~)~K

k h I k' h d I k

th

.,..-

2.. Cover.

.{

,

'5:"':IJ"~1

> noc

up

t e oc mg was

er

an

sac

en e

3.

Diaphragm.

6.

~...

flywheel retaining screw three

or

four threads.

A.I8

~

MINI. Issue

1.

4908

mk1-performance-conversions.co.uk

Loading...

Loading...