THE

STEERING

•

•

•

•

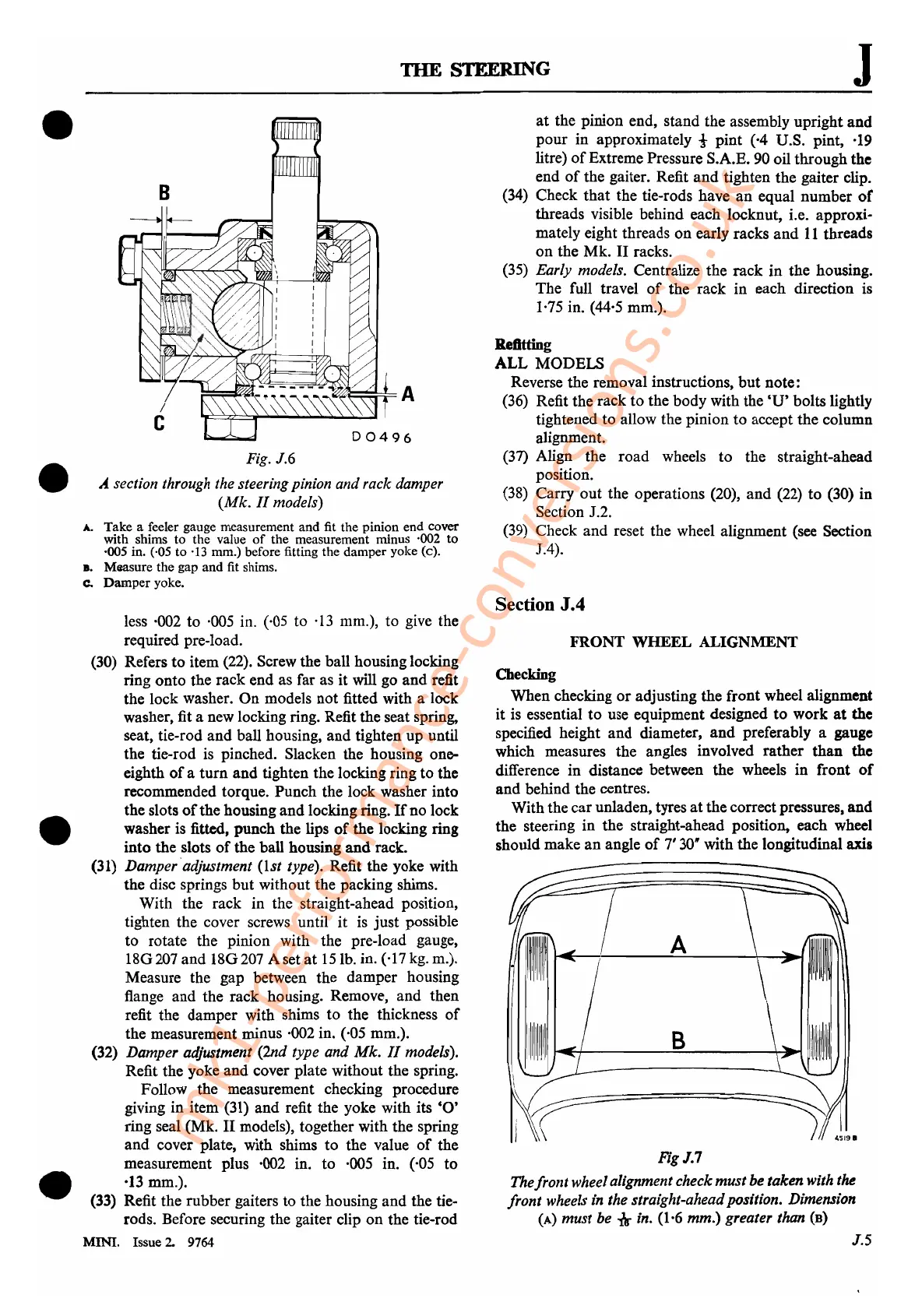

Fig. J.6

A.

section through the steering pinion and rack damper

(Mk.

11

models)

A..

Take a feeler gauge measurement and fit the pinion end cover

with shims to the value

of

the measurement minus ·002

to

·005 in. (,05 to '13 mm.) before fitting the damper yoke (c).

s. Maasure the gap and fit shims.

Co

Damper

yoke.

less ·002 to ·005 in. (,05 to

·13

mm.), to

give

the

required pre-Ioad.

(30)

Refers to item (22). Screw the ball housing locking

ring onto the rack end as far as it will go and refit

the lock washer. On models not fitted with a lock

washer, fit a new locking ring. Refit the seat spring,

seat, tie-rod and ball housing, and tighten up until

the tie-rod

is

pinched. Slacken the housing one-

eighth

of

a turn and tighten the locking ring to the

recommended torque. Punch the lock washer into

the slots

of

the housing and locking ring.

If

no lock

washer is

fitted, punch the lips

of

the locking ring

into the slots

of

the ball housing and rack.

(31)

Damperadjustment

(Ist

type). Refit the yoke with

the disc springs but without the packing shims.

With the rack in the straight-ahead position,

tighten the cover screws until

it

is

just possible

to rotate the pinion with the pre-Ioad gauge,

18G207 and 18G207 A set

at

15

lb. in. (,17

kg.

m.).

Measure the gap between the damper housing

flange and the rack housing. Remove, and then

refit the damper with shims to the thickness

of

the measurement minus ·002 in. (,05 mm.).

(32) Damper adjustment (2nd type and

Mk.

11

models).

Refit the yoke and cover plate without the spring.

Follow the measurement checking procedure

giving in item

(31)

and refit the yoke with its

'0'

ring seal (Mk.

II

models), together with the spring

and cover plate, with shims to the value

of

the

measurement plus

·002 in. to ·005 in. (,05 to

·13 mm.).

(33)

Refit the rubber gaiters to the housing and the tie-

rods. Before securing the gaiter clip on the tie-rod

MINI. Issue 2. 9764

J

at

the pinion end, stand the assembly upright and

pour in approximately

t pint (·4 D.S. pint, ·19

litre)

of

Extreme Pressure S.A.E.

90

oil throughthe

end

of

the gaiter. Refit

and

tighten the gaiter clip.

(34) Check that the tie-rods have

an

equal number

or

threads visible behind each locknut, i.e. approxi-

mately eight threads on early racks and

11

threads

on the Mk.

11

racks.

(35) Early models. Centralize the rack

in

the housing.

The full travel

of

the rack in each direction is

I

·75

in.

(44·5

mm.).

Refitting

ALL MODELS

Reverse the removal instructions, but note:

(36)

Refit the rack to the body with the 'u' bolts lightly

tightened to allow the pinion to accept the column

alignment.

(37)

Align the road wheels to the straight-ahead

position.

(38)

Carry out the operations (20), and (22) to (30) in

Section J.2.

(39)

Check and reset the wheel alignment (see Section

JA).

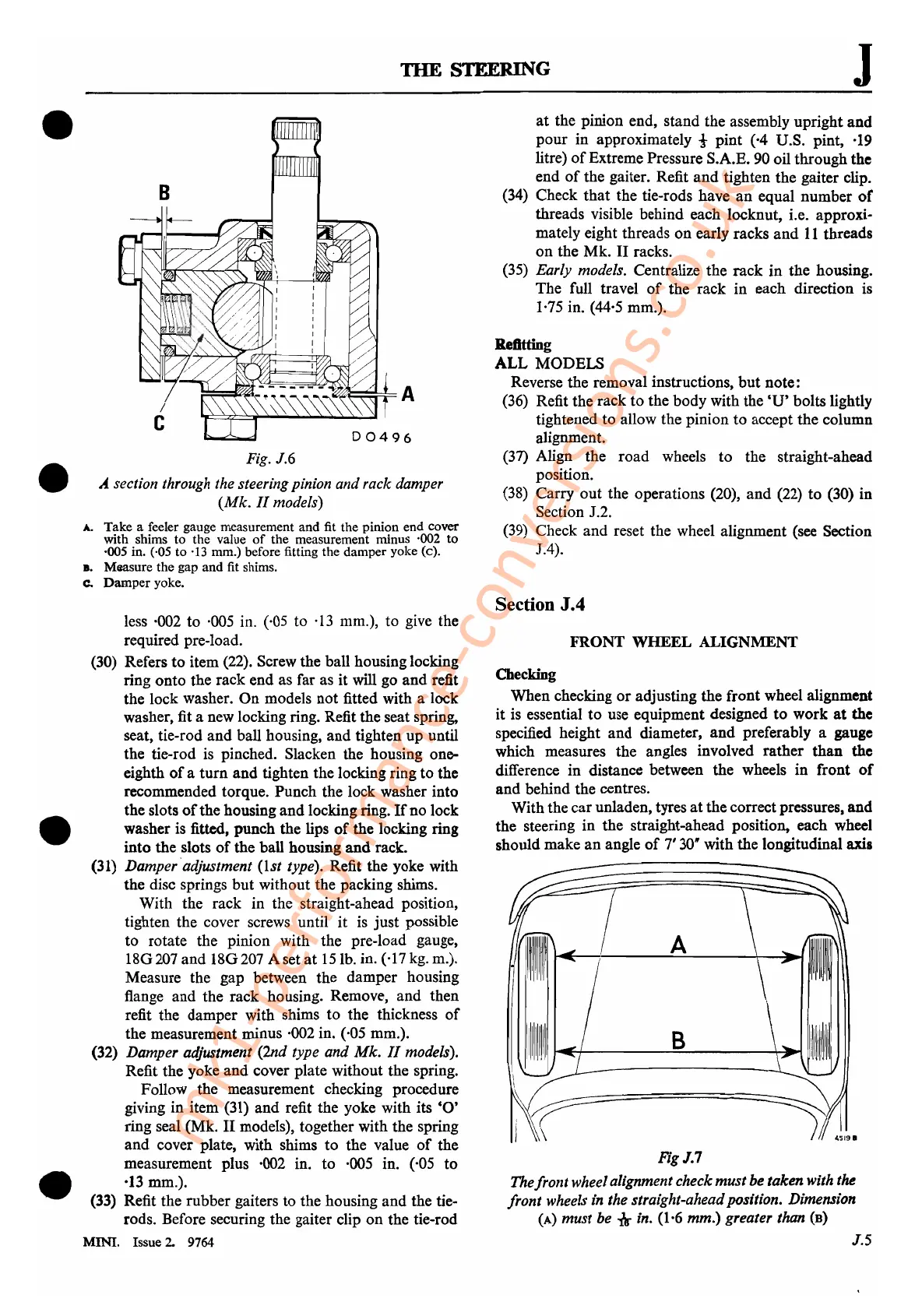

Section

J.4

FRONT

WHEEL

ALIGNMENT

Checking

When checking

or

adjusting the front wheel alignment

it

is

essential to use equipment designed to work

at

the

specified height and diameter, and preferably a gauge

which measures the angles involved rather than the

difference in distance between the wheels in front

of

and behind the centres.

With the car unladen, tyres

at

the correct pressures, and

the steering in the straight-ahead position, each wheel

should make an angle

of

7'

30"

with the longitudinal axis

A

B

FigJ.7

The

front

wheelalignment check

must

be taken with the

front

wheels in the straight-aheadposition. Dimension

(A)

must

be

-«

in. (1·6

mm.)

greater than

(B)

J.5

mk1-performance-conversions.co.uk

Loading...

Loading...