THE

ENGINE

•

•

(8)

Use Service tools 18G 304 with adaptor set

18G 304 N (cadmium-plated) to remove the

fly-

wheel.

NOTE.-The

black screws from set 18G

304

M

must not be used on the diaphragm clutch.

(9) Screw the three adaptor screws into the flywheel

and fit the plate

of

tool 18G

304

over the screws

with the retaining nuts screwed on evenly to keep

the plate parallel with the flywheel.

(10) Screw the centre bolt

of

adaptor set 18G

304

N

through the plate

of

tool 18G

304.

Hold the

fly-

wheel from turning and tighten the centre bolt

against the flywheel retaining screw until the

fly-

wheel

is

released from the crankshaft taper.

(11) Unscrew

and

remove the flywheel retaining screw

and keyed washer and withdraw the flywheel.

Inspecting

(12) Inspect the cover for elongation

of

the driving pin

holes. .

(13)

Inspect the driving pins for ridging and wear; fit

three new pins

if

any are worn.

(14)

Inspect the driving straps; fit three new ones

if

any

are worn.

A

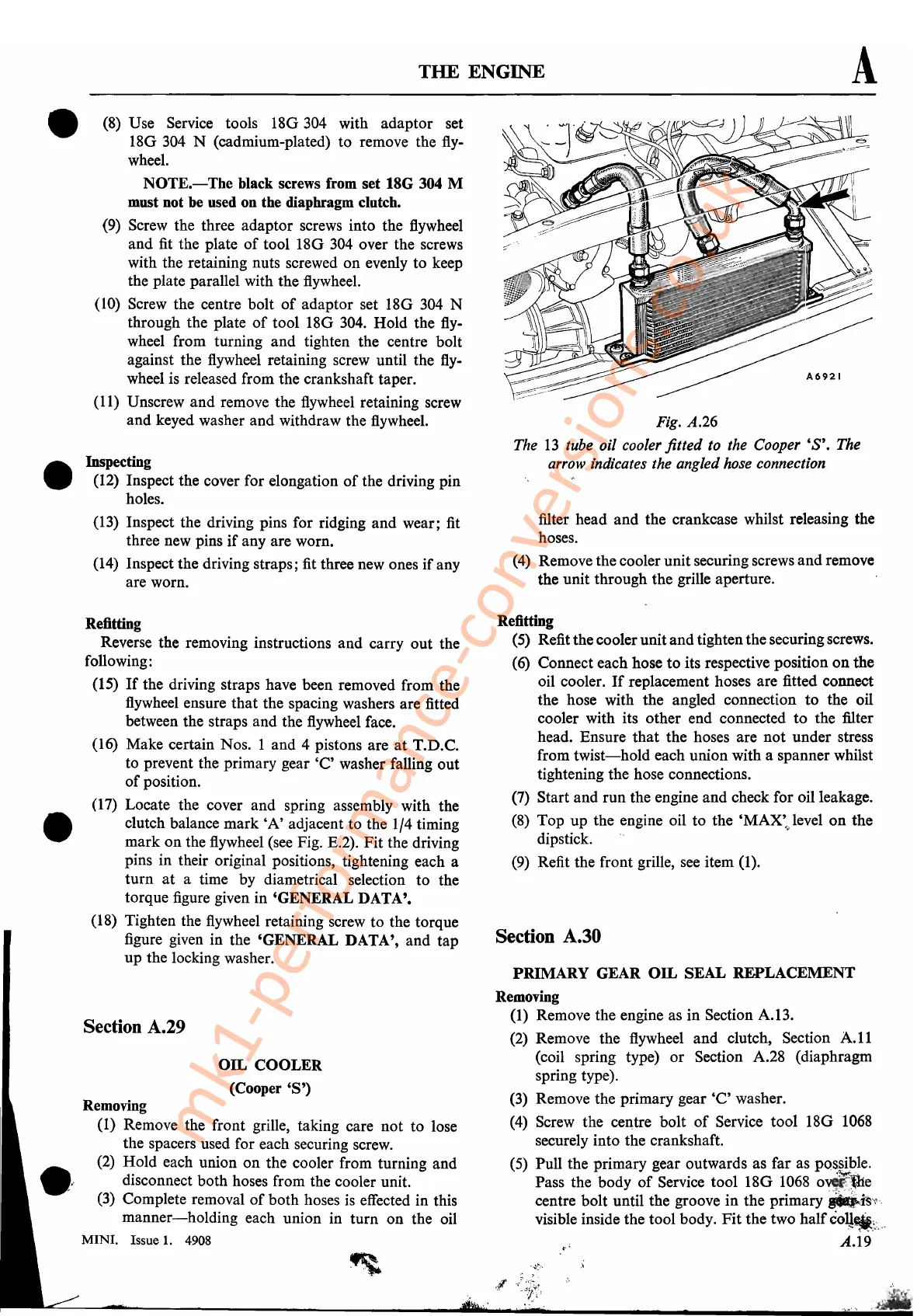

Fig. A.26

The

13

tube oil cooler fitted to the

Cooper'S'.

The

arrow indicates the angled hose connection

filter head and the crankcase whilst releasing the

hoses.

(4)

Remove the cooler unit securing screws and remove

the unit through the grille aperture.

•

Refitting

Reverse the removing instructions and carry out the

following:

(15)

If

the driving straps have been removed from the

flywheel ensure that the spacing washers are fitted

between the straps and the flywheel face.

(16) Make certain Nos. 1 and 4 pistons are

at

T.D.C.

to prevent the primary gear

'e' washer falling out

of

position.

(17)

Locate the cover and spring assembly with the

clutch balance mark

'A'

adjacent to the 1/4 timing

mark on the flywheel (see Fig. E.2). Fit the driving

pins in their original positions, tightening each a

turn

at

a time by diametrical selection to the

torque figure given in 'GENERAL DATA'.

(18) Tighten the flywheel retaining screw to the torque

figure given in the 'GENERAL DATA', and tap

up the locking washer.

Section A.29

OIL

COOLER

(Cooper'S')

Removing

(1) Remove the front grille, taking care not to lose

the spacers used for each securing screw.

(2)

Hold each union on the cooler from turning and

disconnect both hoses from the cooler unit.

(3)

Complete removal

of

both hoses

is

effected in this

manner-holding

each union in turn on the oil

MINI. Issue

1.

4908

Refitting

(5)

Refit the coolerunit andtighten the securing screws.

(6)

Connect each hose

to

its respective position

on

the

oil cooler.

If

replacement hoses are fitted connect

the hose with the angled connection

to

the oil

cooler with its other end connected to the filter

head. Ensure that the hoses are not under stress

from

twist-hold

each union with a spanner whilst

tightening the hose connections.

(7)

Start and run the engine and check for oil leakage.

(8)

Top up the engine oil to the

'MAX'!evel

on

the

dipstick. "

(9)

Refit the front grille, see item (1).

Section A.30

PRIMARY GEAR

OIL

SEAL REPLACEMENT

Removing

(1) Remove the engine as in Section A.13.

(2)

Remove the flywheel and clutch, Section

A.ll

(coil spring type) or Section A.28 (diaphragm

spring type).

(3)

Remove the primary gear

'C'

washer.

(4)

Screw the centre bolt

of

Service tool 18G

1068

securely into the crankshaft.

(5)

Pull the primary gear outwards as far as possible.

Pass the body

of

Service tool 18G

1068

ov~e

centre bolt until the groove in the

primary_Js~\

visible inside the tool body.

Fit

the two half

co~~\:

..

:

,.'

A.19

mk1-performance-conversions.co.uk

Loading...

Loading...