A

THE

ENGINE

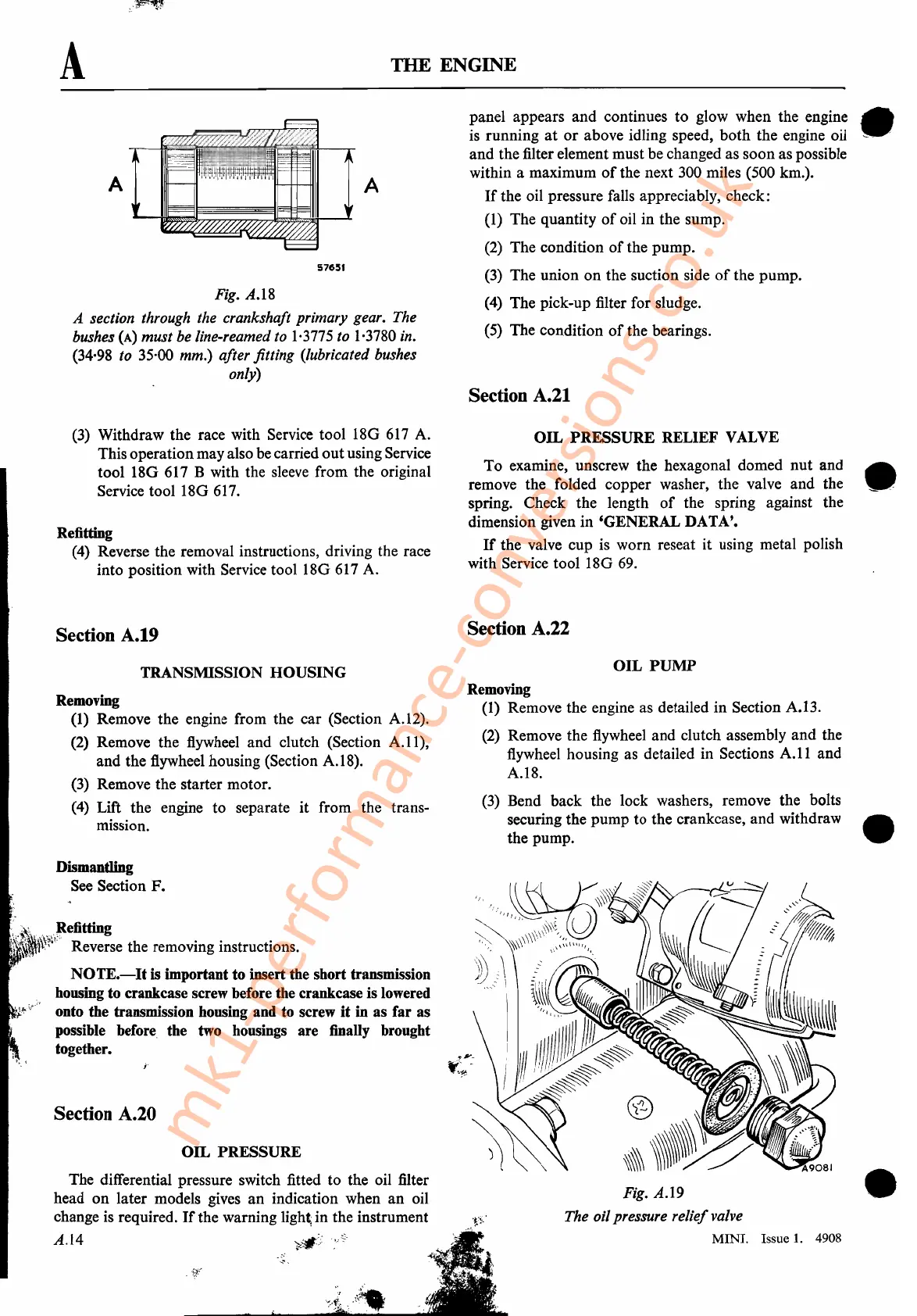

Fig. A.I8

A section through the crankshaft primary gear. The

bushes

(A)

must be line-reamed to

1·3775

to

1·3780

in.

(34·98 to 35·00 mm.) after fitting (lubricated bushes

only)

A

57651

A

panel appears and continues to glow when the engine •

is

running

at

or

above idling speed, both the engine oil

.~",'

and the filter element must be changed as soon as possible

within a maximum

of

the next 300 miles (500 km.).

If

the oil pressure falls appreciably, check:

(1)

The quantity

of

oil in the sump.

(2)

The condition

of

the pump.

(3)

The union

on

the suction side

of

the pump.

(4)

The pick-up filter for sludge.

(5)

The condition

of

the bearings.

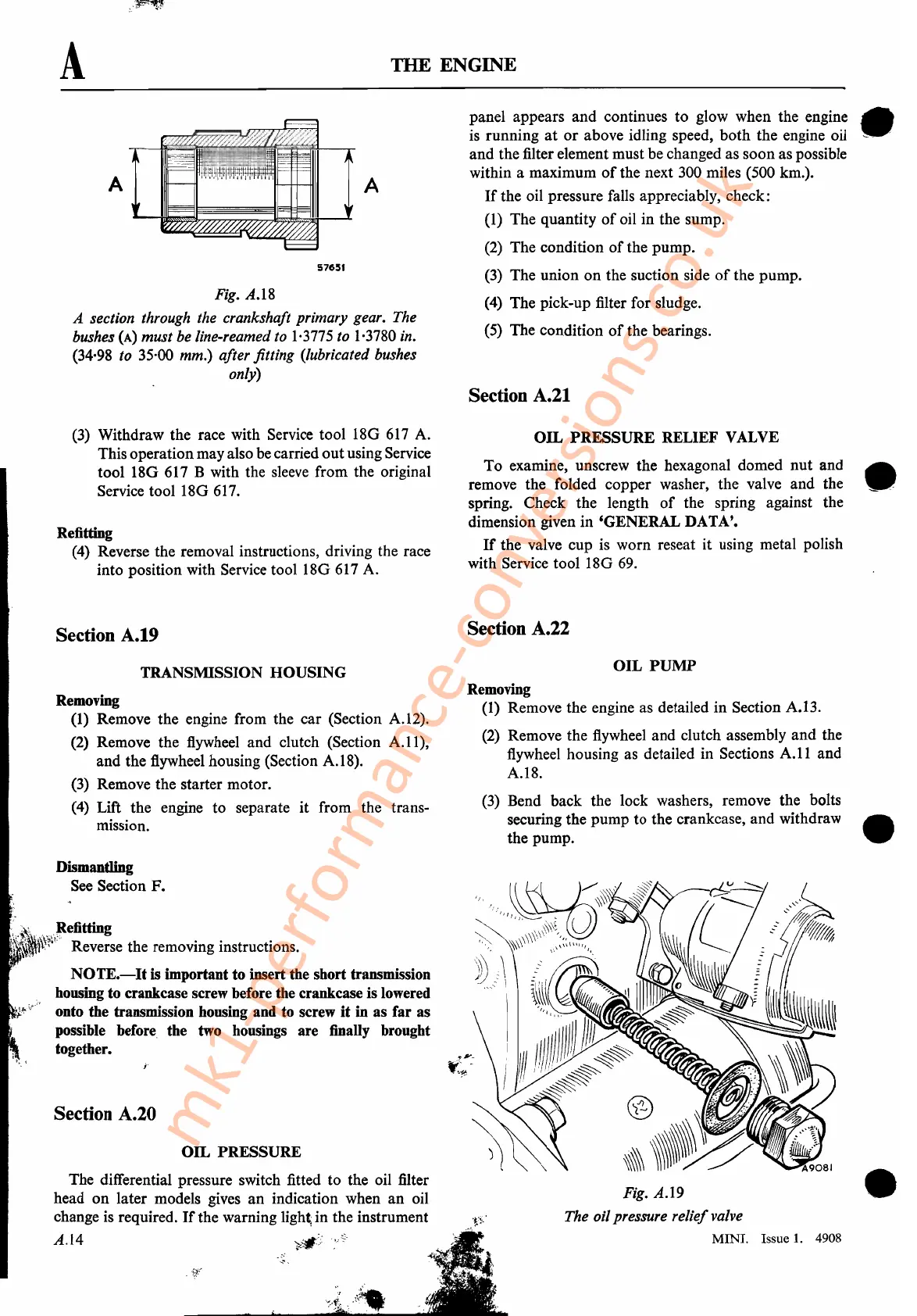

Section A.21

(3)

Withdraw the race with Service tool 18G

617

A.

This operationmay also

be

carried outusing Service

tool 18G

617

B with the sleeve from the original

Service tool 18G

617.

Refitting

(4)

Reverse the removal instructions, driving the race

into position with Service tool 18G

617

A.

OIL

PRESSURE RELIEF VALVE

To examine, unscrew the hexagonal domed nut and •

remove the folded copper washer, the valve and the

--=_

spring. Check the length

of

the spring against the

dimension given in 'GENERAL DATA'.

If

the valve cup is worn reseat it using metal polish

with Service tool 18G

69.

Section A.19

Section A.22

TRANSMISSION HOUSING

Removing

(1)

Remove the engine from the car (Section A.12).

(2)

Remove the flywheel and clutch (Section

A.ll),

and the flywheel housing (Section A.I8).

(3)

Remove the starter motor.

(4)

Lift the engine to separate it from the trans-

mission.

OIL

PUMP

Removing

(1)

Remove the engine as detailed in Section A.13.

(2)

Remove the

flywheel

and clutch assembly and the

flywheel

housing as detailed in Sections

A.11

and

A.I8.

(3)

Bend back the lock washers, remove the bolts

securing the pump to the crankcase, and withdraw

•.

,

the pump.

OIL

PRESSURE

•

Fig. A.I9

The oil pressure relief valve

MINI. Issue

1.

4908

Dismantling

See

Section F.

The differential pressure switch fitted to the oil filter

head

on

later models gives an indication when an oil

change

is

required.

If

the warning

ligh~

in the instrument

A.14

Section A.20

J,.~~

VI'

~efitting

l'"~~rW~·l'

Reverse the removing instructions.

NOTE.-It

is

important to insert the short transmission

housing to crankcase screw before the crankcase is lowered

onto the transmission housing and to screw

it

in as far as

possible

before,

the

two

housings are finally brought

together.

mk1-performance-conversions.co.uk

Loading...

Loading...