Removing

(1) Remove the engine (Section A.12), the rocker shaft

assembly (Section A.5), the push-rods and tappets

(Section A.9), and the distributor (Section A.I0).

(2)

Unscrew the camshaft locating plate

and

withdraw

the camshaft.

(3)

If

the camshaft bearings are worn, remove the

flywheel housing and transmission case (Sections

A.18 and A.19).

•

THE

ENGINE

Section A.23

CAMSHAFT

A

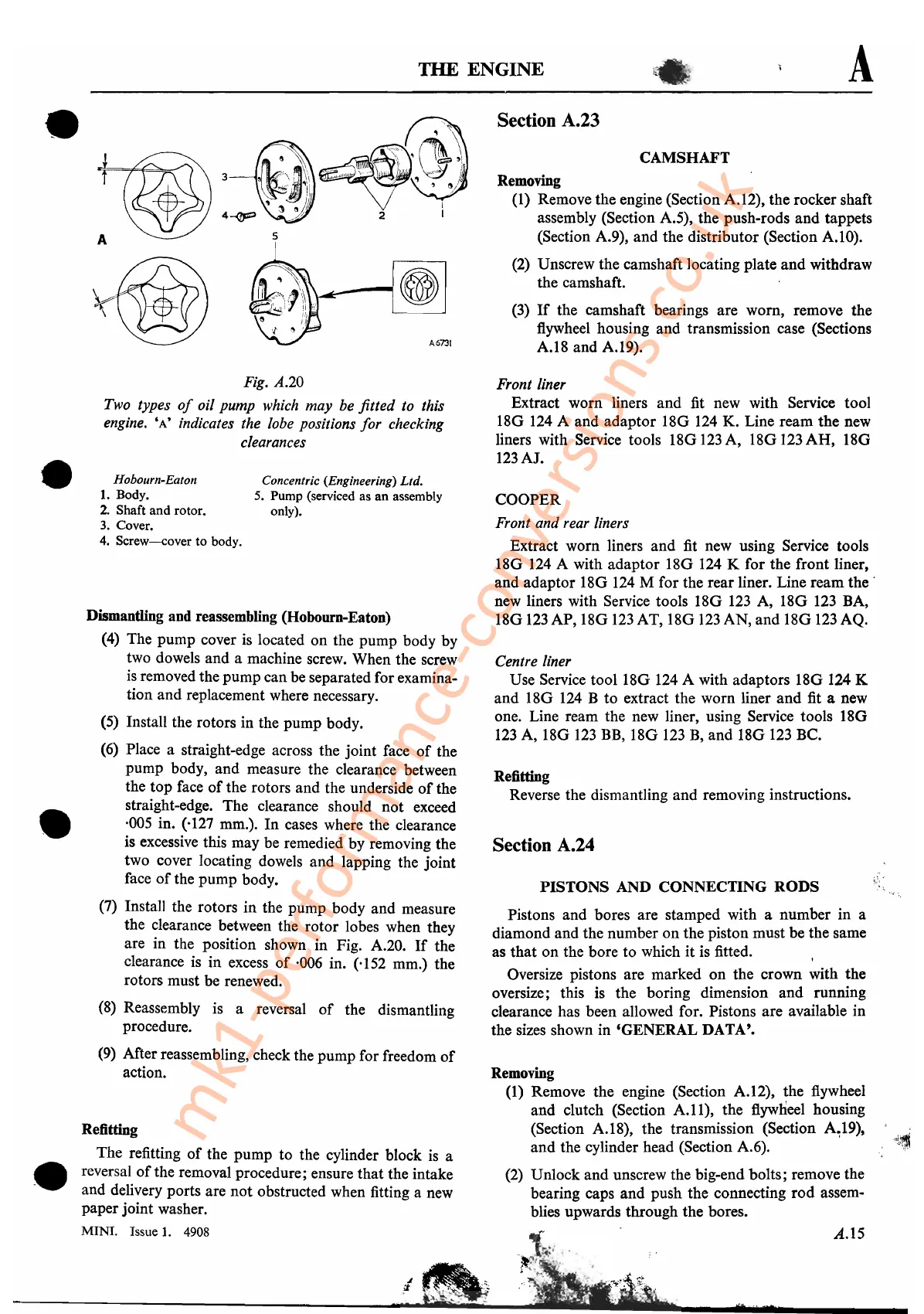

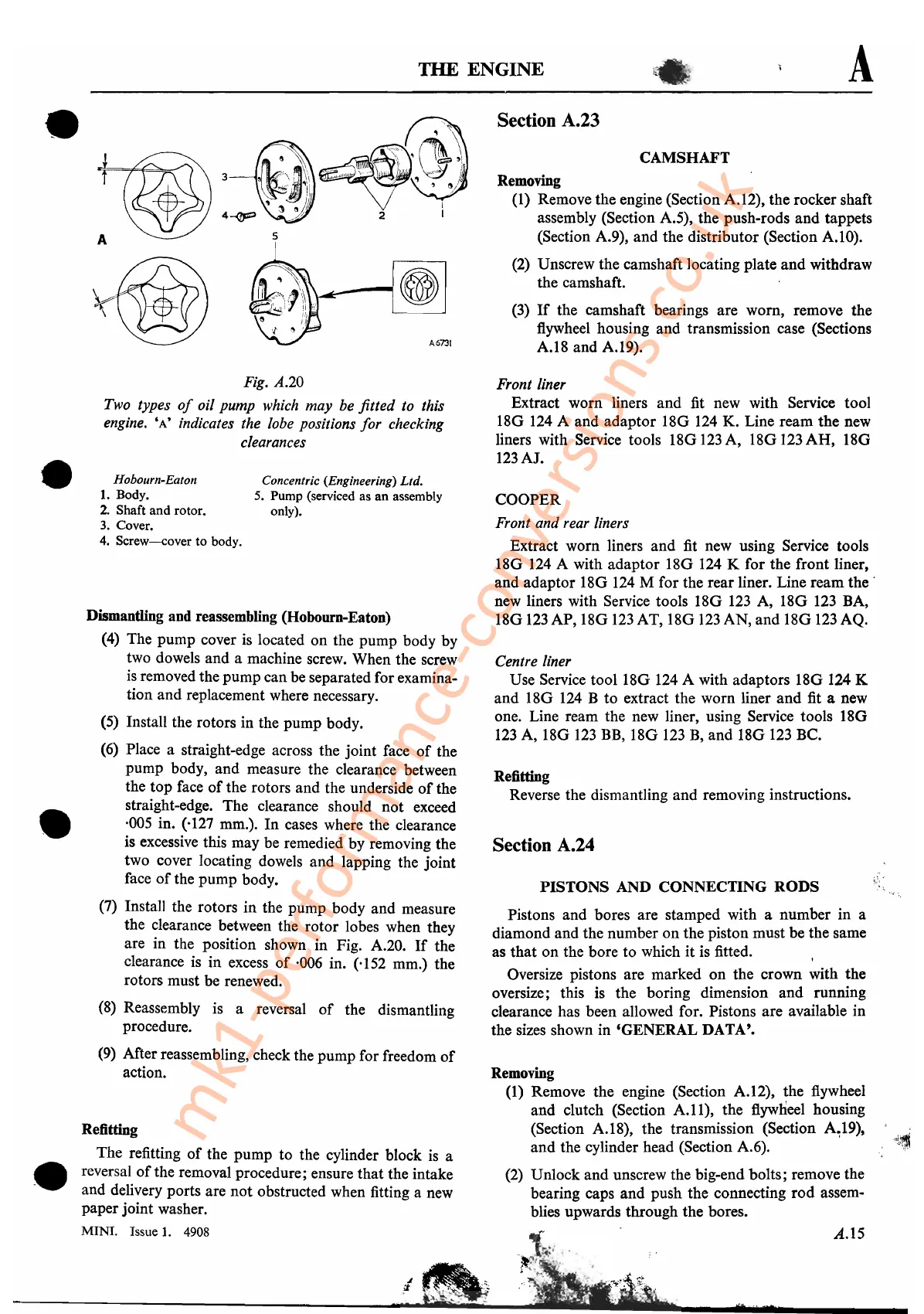

Fig. A.20

Two types

of

oil pump which may be fitted to this

engine.

'A'

indicates the lobe positions

for

checking

clearances

Refitting

The refitting

of

the pump to the cylinder block

is

a

reversal

of

the removal procedure; ensure that the intake

and delivery ports are not obstructed when fitting a new

paper joint washer.

MINI. Issue

1.

4908

A.15

Refitting

Reverse the dismantling and removing instructions.

Front liner

Extract worn liners

and

fit new with Service tool

180

124 A and adaptor

180

124

K. Line ream

the

new

liners with Service tools

180123

A,

180123

AH,

18G

123AJ.

COOPER

Front and rear liners

Extract worn liners

and

fit

new using Service tools

180

124

A with adaptor

180

124 K for the front liner,

and adaptor 18G

124

M for the rear liner. Line ream

the·

new liners with Service tools

180

123

A, 18G

123

BA,

18G

123

AP,

180

123

AT,

180123

AN, and 18G

123

AQ.

Centre liner

Use Service tool

180

124

A with adaptors

180

124 K

and

18G

124

B to extract the worn liner

and

fit a new

one. Line ream the new liner, using Service tools

180

123

A, 18G

123

BB,

180

123

B,

and

180

123

BC.

Pistons and bores are stamped with a number in a

diamond and the number on the piston must be the same

as

that

on the bore to which it is fitted.

Oversize pistons are marked on the crown with the

oversize; this is the boring dimension and running

clearance has been allowed for. Pistons are available in

the sizes shown in 'GENERAL DATA'.

PISTONS

AND CONNECTING

RODS

Section A.24

Removing

(1)

Remove the engine (Section A.12), the flywheel

and clutch (Section

A.ll),

the flywheel housing

(Section A.18), the transmission (Section

A,,:19),

and

the cylinder head (Section A.6).

(2)

Unlock and unscrew the big-end bolts; remove the

bearing caps and push the connecting

rod

assem-

blies upwards through the bores.

Concentric (Engineering) Ltd.

5.

Pump (serviced as

an

assembly

only).

Hobourn-Eaton

1.

Body.

2.

Shaft and rotor.

3.

Cover.

4.

Screw-cover

to body.

Dismantling and reassembling (Hobourn-Eaton)

(4)

The pump cover

is

located on the pump body by

two dowels and a machine screw. When the screw

is

removed the pump can be separated for examina-

tion and replacement where necessary.

(5)

Install the rotors in the pump body.

(6)

Place a straight-edge across the joint face

of

the

pump body, and measure the clearance between

the

top

face

of

the rotors and the underside

of

the

straight-edge. The clearance should not exceed

·005 in. (,127 mm.).

In

cases where the clearance

is excessive this may be remedied by removing the

two cover locating dowels and lapping the joint

face

of

the pump body.

(7) Install the rotors

in

the pump body and measure

the clearance between the rotor lobes when they

are in the position shown in Fig. A.20.

If

the

clearance is in excess

of

·006 in. ('152 mm.) the

rotors must be renewed.

(8)

Reassembly is a reversal

of

the dismantling

procedure.

(9)

After reassembling, check the pump for freedom

of

action.

•

•

•

mk1-performance-conversions.co.uk

Loading...

Loading...