THE

CLUTCH

•

•

•

•

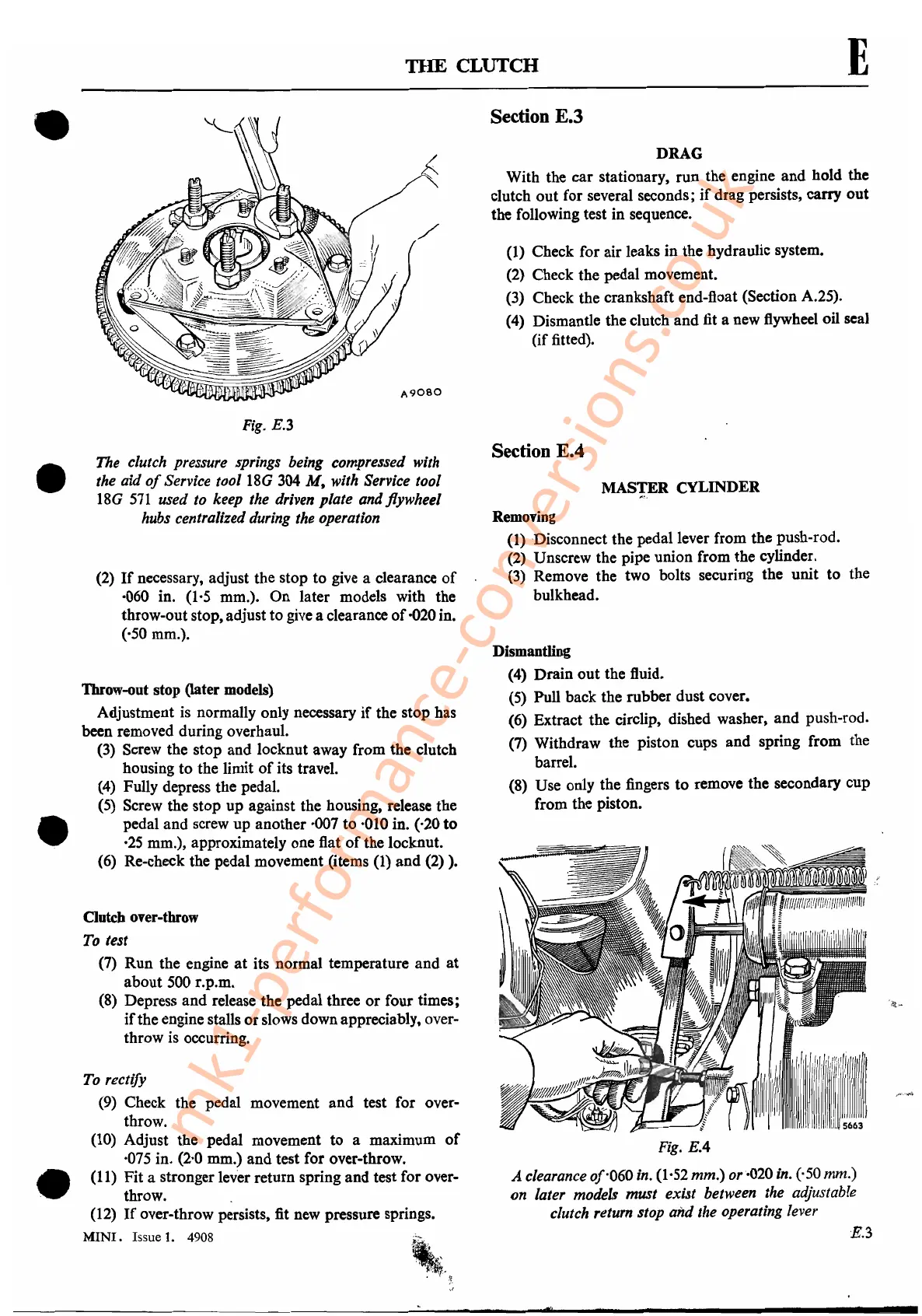

Fig.

E.3

The clutch pressure springs being compressed with

the aid

of

Service tool

18G

304

M,

with Service tool

18G

571

used to keep the driven plate and flywheel

hubs centralized during the operation

(2)

If

necessary, adjust the stop

to

give a clearance

of

·060 in. (1·5 mm.). On later models with the

throw-out stop, adjust to give a clearance

of

·020 in.

(·50 mm.).

Throw-out stop Oater

models)

Adjustment is normally only necessary

if

the stop has

been removed during overhaul.

(3) Screw the stop and locknut away from the clutch

housing to the limit

of

its travel.

(4)

Fully depress the pedal.

(5) Screw the stop up against the housing, release the

pedal and screw up another ·007 to ·010 in. (·20

to

·25 mm.), approximately one flat

of

the locknut.

(6) Re-check the pedal movement (items

(I)

and

(2) ).

Clutch over-throw

To

test

(7)

Run

the engine

at

its normal temperature

and

at

about 500 r.p.m.

(8)

Depress

and

release the pedal three

or

four times;

if

the engine stalls

or

slows down appreciably, over-

throw is occurring.

To

rectify

(9)

Check the pedal movement and test for over-

throw.

(l0) Adjust the pedal movement

to

a maximum

of

·075 in. (2·0 mm.) and test for over-throw.

(11) Fit a stronger lever return spring

and

test for over-

throw.

(12)

If

over-throw persists, fit new pressure springs.

MINI.

Issue

1.

4908

E

Section E.3

DRAG

With the car stationary, run the engine

and

hold the

clutch

out

for several seconds;

if

drag persists, carry

out

the following test in sequence.

(I)

Check for air leaks in the hydraulic system.

(2) Check the pedal movement.

(3) Check the crankshaft end-float (Section A.25).

(4) Dismantle the clutch

and

fit a new flywheel oil seal

(if

fitted).

Section E.4

MASTER CYLINDER

Removing

(l)Disconnect

the pedal lever from the push-rod..

(2) Unscrew the pipe union from the cylinder.

(3)

Remove the two bolts securing the unit

to

the

bulkhead.

Dismantling

(4) Drain

out

the fluid.

(5)

Pull back the rubber dust cover.

(6) Extract the circlip, dished washer,

and

push-rod.

(7) Withdraw the piston cups and spring from the

barrel.

(8) Use only the fingers

to

remove the secondary cup

from the piston.

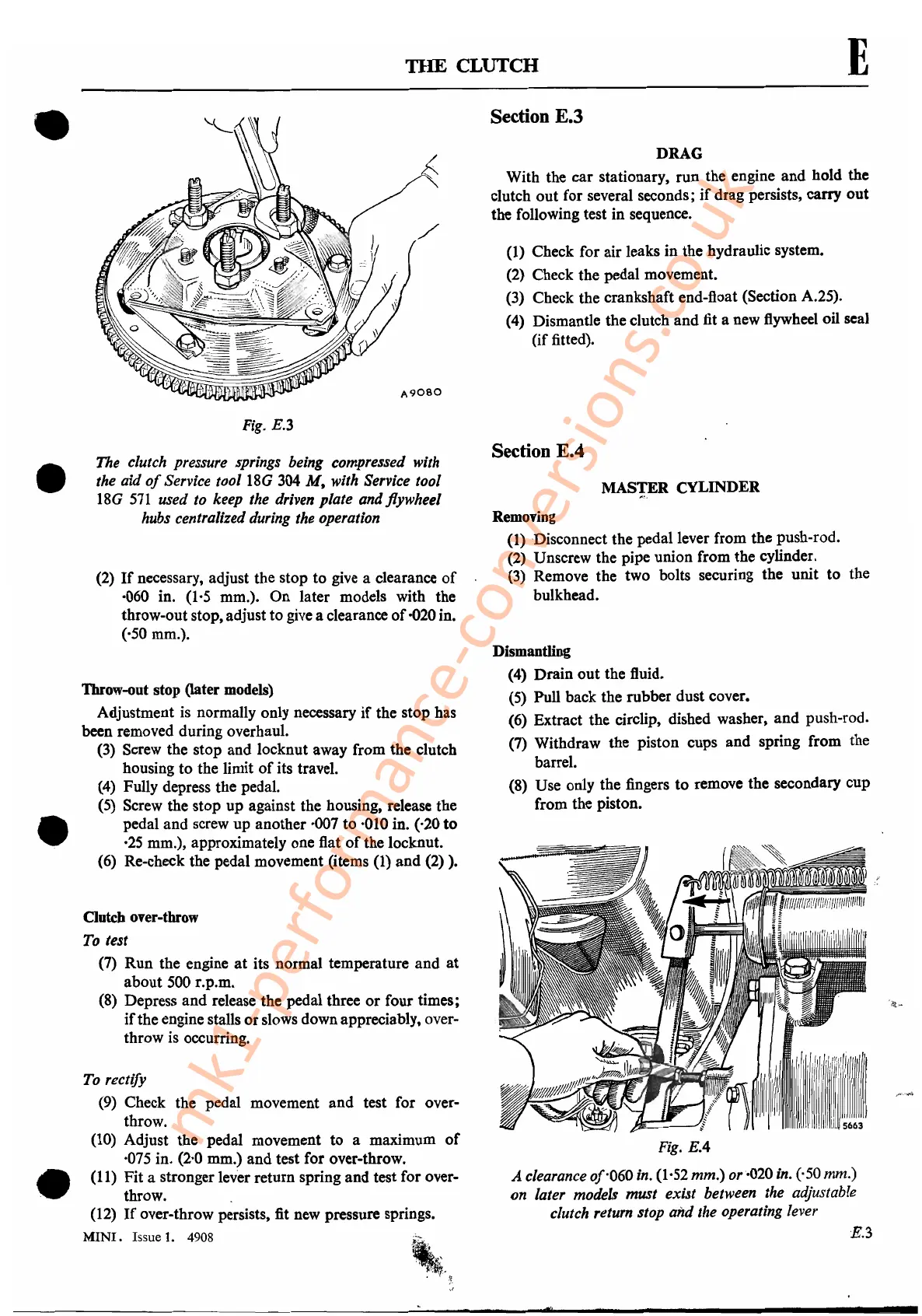

Fig.

EA

A clearance of·060in. (1·52 mm.) or·020 in. (·50 mm.)

on later models must exist between the adjustable

clutch return stop and the operating lever

E.3

mk1-performance-conversions.co.uk

Loading...

Loading...