E

t

THE CLUTCH

•

•

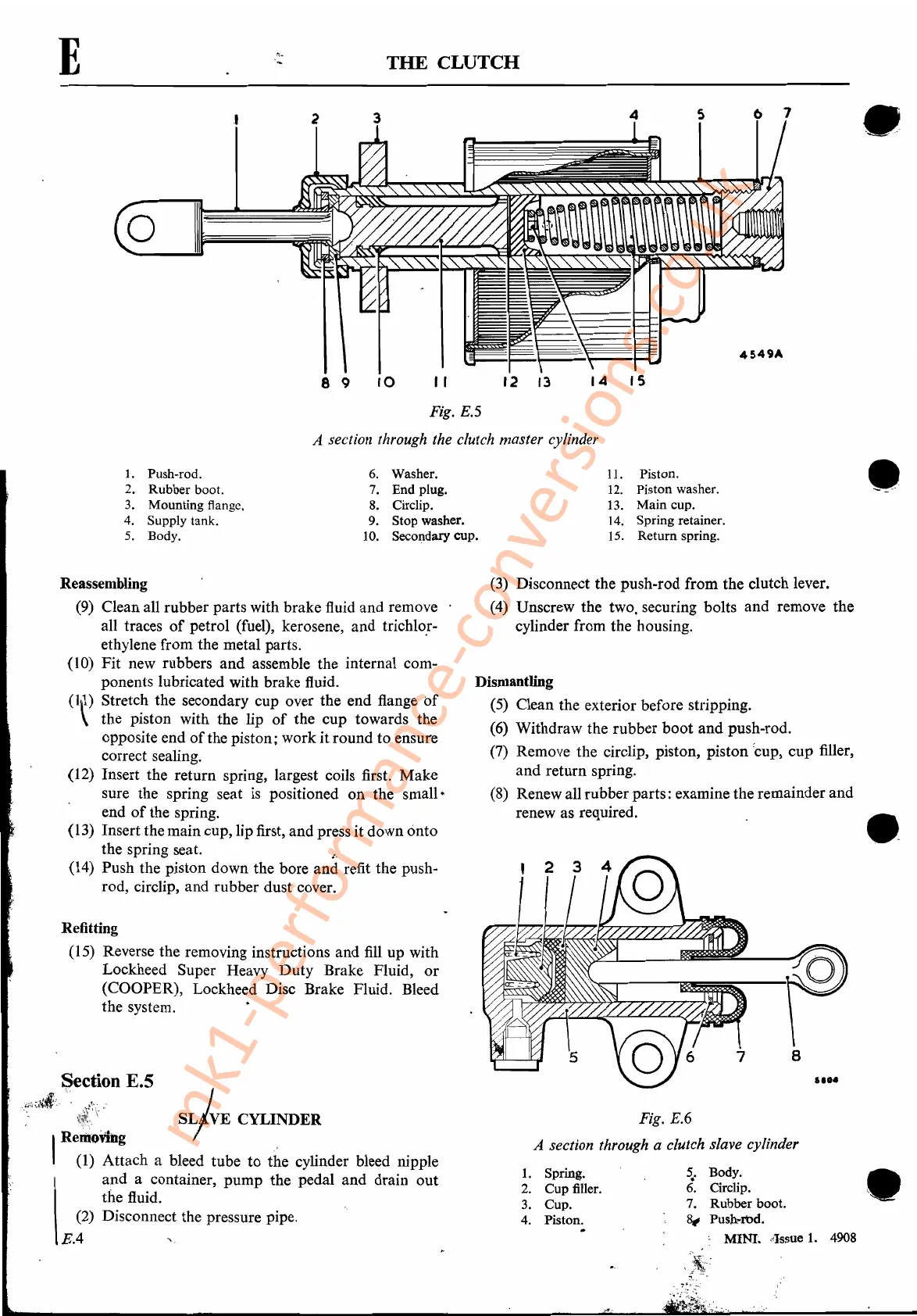

11. Piston.

12. Piston washer.

13.

Main

cup.

14. Spring retainer.

15.

Return

spring.

14

15

12

13

10

6.

Washer.

7.

End

plug.

8. Circlip.

9. Stop washer.

10. Secondary cup.

8 9

I1

Fig. E.5

A section through the clutch master cylinder

1.

Push-rod.

2.

Rubber

boot.

3. Mounting flange.

4. Supply tank.

5.

Body.

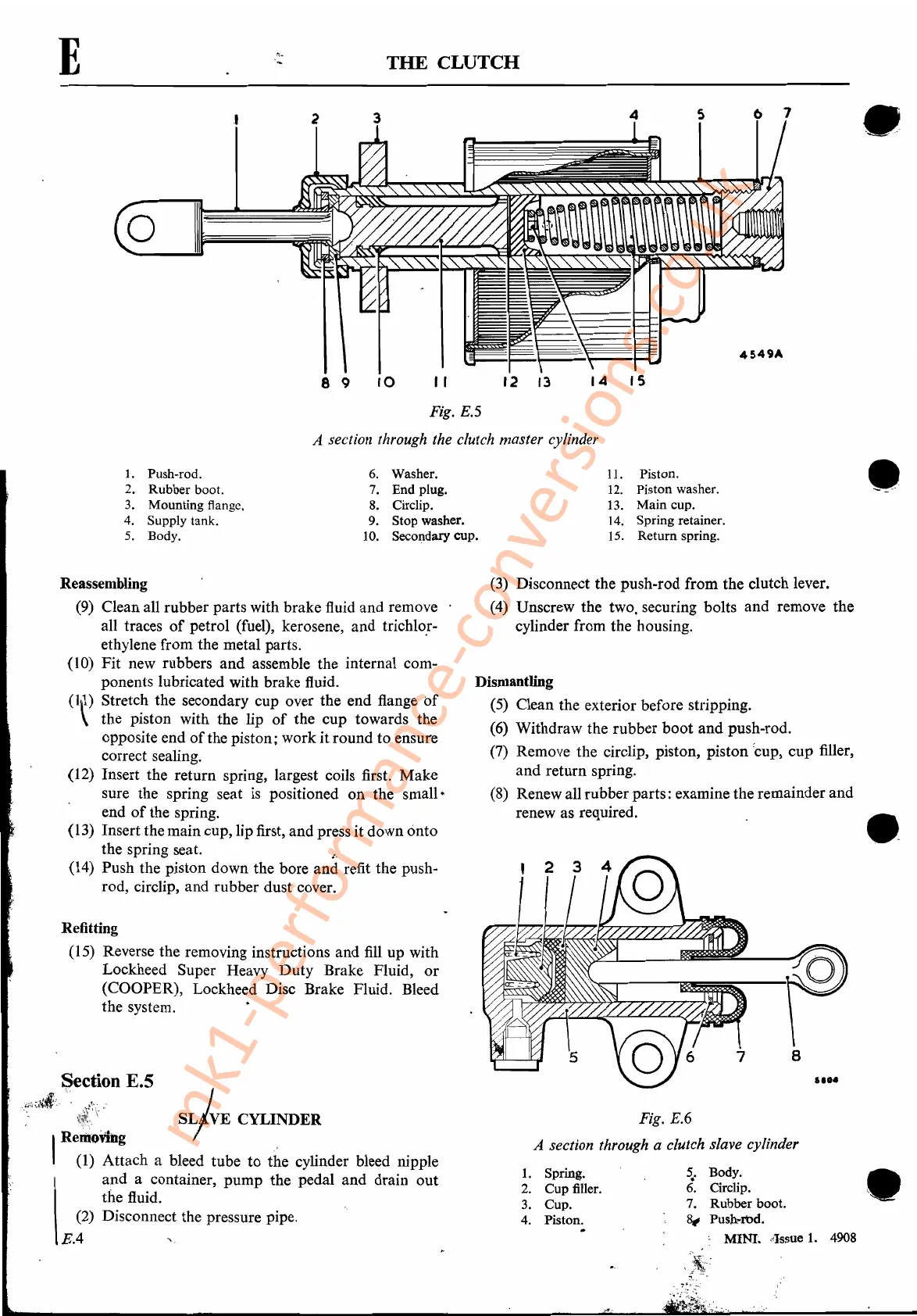

Fig. E.6

A section through a clutch slave cylinder

•

•

~.

Body.

6

..

Circlip.

7.

Rubber

boot.

~

Push

..

"Od.

MINtassue

1.

4908

1.

Spring.

2.

Cup

filler.

3. Cup.

4. Piston.

.

(3)

Disconnect the push-rod from the clutch lever.

(4)

Unscrew the two, securing bolts and remove the

cylinder from the housing.

Dismantling

(5)

Clean the exterior before stripping.

(6)

Withdraw the rubber boot and push-rod.

(7)

Remove the circlip, piston, piston

:cup,cup

filler,

and return spring.

(8)

Renew all rubber parts: examine the remainder and

renew as required.

Refitting

(15)

Reverse the removing instructions arid

fill

up with

Lockheed Super Heavy Duty Brake Fluid,

or

(COOPER), Lockheed Disc Brake Fluid. Bleed

the system.

Reassembling

(9)

Clean all rubber parts with brake fluid and remove

all traces

of

petrol (fuel), kerosene, and trichlor-

ethylene from the metal parts. .

(10) Fit new rubbers and assemble the internal com-

ponents lubricated with brake fluid.

(Ill) Stretch the secondary cup over the end flange

of

\ the piston with the lip

of

the cup towards the

opposite end

of

the piston; work it round to ensure

correct sealing;

(12) Insert the return spring, largest coils first. Make

.sure the spring seat

is

positioned on

the

small"

end

of

the spring.

(13) Insert the main cup, lip first, and press it down onto

the spring seat.

~.

(14) Push the piston down the bore and refit the push-

rod, circlip, and rubber dust cover.

Section E.5

"~~·~tach

a

b:t:eC~~~::der

bleed

fipple

and a container, pump the pedal and drain out

the fluid.

(2)

.Disconnect the pressure pipe.

E.4

".

mk1-performance-conversions.co.uk

Loading...

Loading...