F

"

THE

TRANSMISSION

(5)

Remove the two end

~pvers.

Note the number

of

•..

shims between the housings and the bearings.

(6)

Unscrew the nuts and remove the differential

assembly.

Dismantling

(7)

Withdraw the two differential bearings with

Service tool 18G

2.

(8)

Remove the differential cage from the driving gear

and extract the gear and thrust washer from the

bore

of

the driving gear.

(9)

Tap

out

the taper pin to release both pinions and

thrust washers, pinion spacer, and the remaining

differential gear and washer.

~

,

o·S~,

'k~'~

,

;;r~~

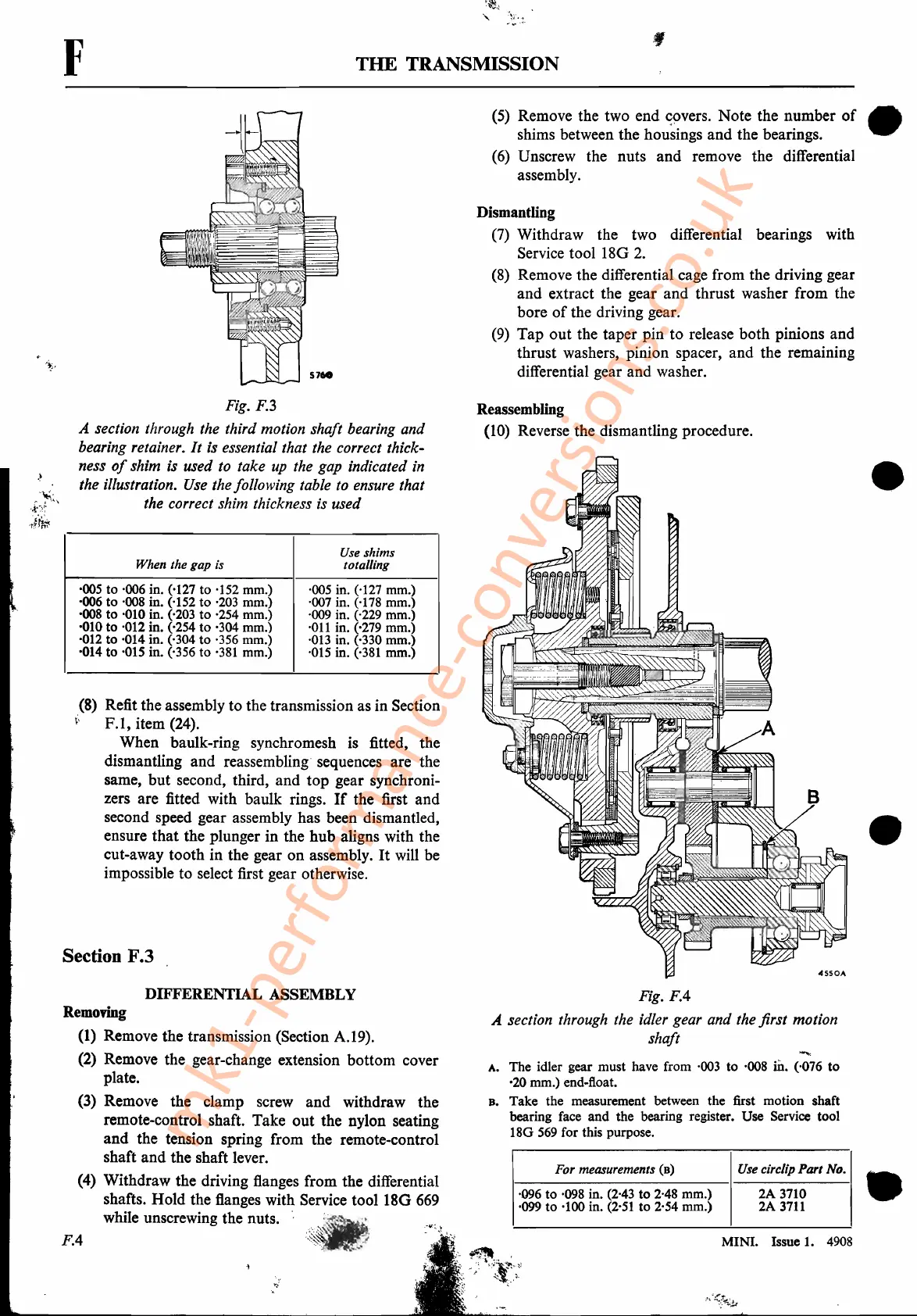

Fig. F.3

A section through the third motion shaft bearing and

bearing retainer.

It

is essential that the correct thick-

ness

of

shim is used to take

up

the gap indicated

in

the illustration.

Use

the following table

to

ensure that

the correct shim thickness

is

used

Use

shims

When the gap is

totalling

'005 to ·006 in. (·127 to ·152 mm.)

·005 in. (·127 mm.)

·006 to

·008

in. (·152 to

·203

mm.)

·007 in.

(·178

mm.)

'008 to ·010 in.

(·203

to ·254 mm.) ·009 in. (·229 mm.)

'010 to ·012 in. (,254 to ·304 mm.)

·011

in. ('279 mm.)

'012 to ·014 in. ('304 to ·356 mm.)

·013

in. (·330 mm.)

'014 to ·015 in. (·356 to

·381

mm.)

·015

in.

(·381

mm.)

(8) Refit the assembly to the transmission as in Section

~,

F.I,

item (24).

When baulk-ring synchromesh is fitted, the

dismantling and reassembling sequences are the

same, but second, third, and top gear synchroni-

zers are fitted with baulk rings.

If

the first and

second speed gear assembly has been dismantled,

ensure that the plunger in the hub aligns with the

cut-away tooth in the gear

on

assembly.

It

will be

impossible to select first gear otherwise.

Section F.3

DIFFERENTIAL ASSEMBLY

Removing

(1)

Remove the transmission (Section A.19).

(2) Remove the gear-change extension bottom cover

plate.

(3) Remove the clamp screw and withdraw the

remote-control shaft. Take out the nylon seating

and the tension spring from the remote-control

shaft and the shaft lever.

(4) Withdraw the driving flanges from the differential

shafts. Hold the flanges with Service tool

180

669

F.4 while unscrewing

the

nuts.

,.%",.

Reassembling

(10)

Reverse the dismantling procedure.

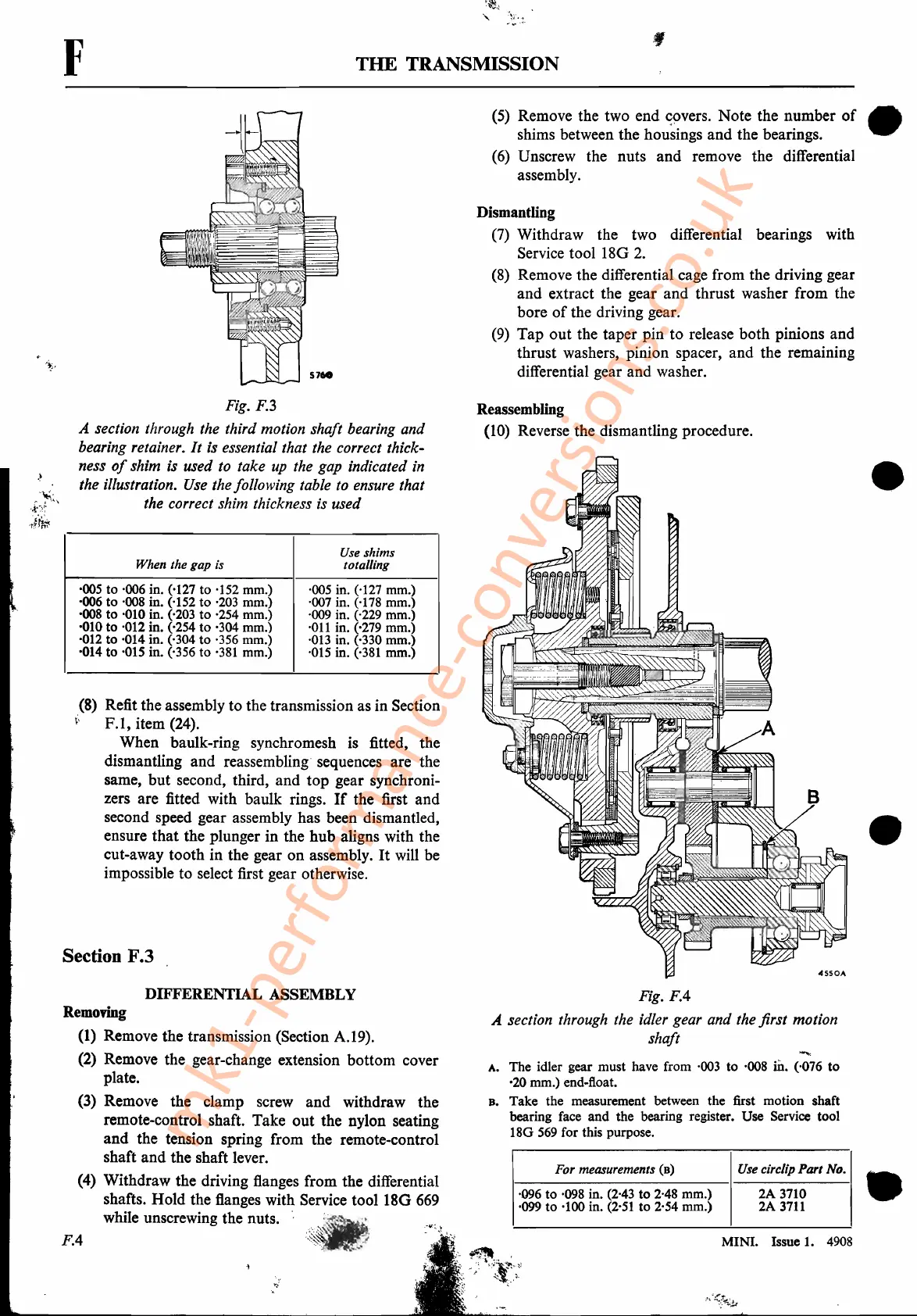

Fig.

FA

A section through the idler gear and the first motion

shaft

A. The idler gear must have from

·003

to ·008

rn.

(·076 to

'20 mm.) end-float.

B. Take the measurement between the first motion shaft

bearing face and the bearing register. Use Service tool

180

569

for this purpose.

For measurements (0) Use circ/ip Part No.

·096 to ·098 in.

(2·43

to 2·48 mm.) 2A 3710

·099 to ·100 in.

(2·51

to 2·54 mm.) 2A

3711

MINI. Issue

1.

4908

.t~~;:

-;-'

•

•

•

mk1-performance-conversions.co.uk

Loading...

Loading...