THE TRANSMISSION

•

(27)

Refers to item

(2).

Use Service tool

180

581

to

refit the idler bearing.

With the housing nuts tight, idler gear end-

float must be

·003 to ·008 in. ('08 to ·20 mm.) and

range

of

thrust washers

of

various thicknesses are

available.

F

(3)

Withdraw the third speed gear and bush, the rear

thrust washer, and the first speed gear and hub.

(4)

When separating the second, third, and fourth

striking dog from the hub and cone assemblies

take care not to lose the balls and springs in each

hub.

•

Section F.2

THIRD

MOTION

SHAvr

Remove the shaft assembly from the transmission as

detailed in Section

F.l.

Dismantling

(1)

Withdraw the top and third gear synchromesh

hub from the front end

of

the shaft.

(2)

Press the front thrust washer plunger and turn the

washer until the splines register with those on the

shaft. Remove the plunger and spring.

Reassembling

.•

i.

.

(5) Refers to item

(3).

Fit the cone side

of

the hub

on.".".

the same side as the plain side

of

the first gear

teeth.

(6)

Refers to item

(2).

Fit the third speed gear, plain

side first, and insert the spring and locking

plunger. Depress the plunger and

fit

the thrust

washer in position. The essential interference

fit

of

the bushes

will

have been destroyed on removal.

Fit

new

bushes

by

heating them to 180 to 200°

C.

(356 to 392

0

F.), and sliding on the shaft. Natural

cooling

will

establish a permanent shrink-fit.

(7)

Second and third speed gear end-float must

be

between ·0035 and ·0055 in. (,09 and ·14 mm.).

•

F.3

c

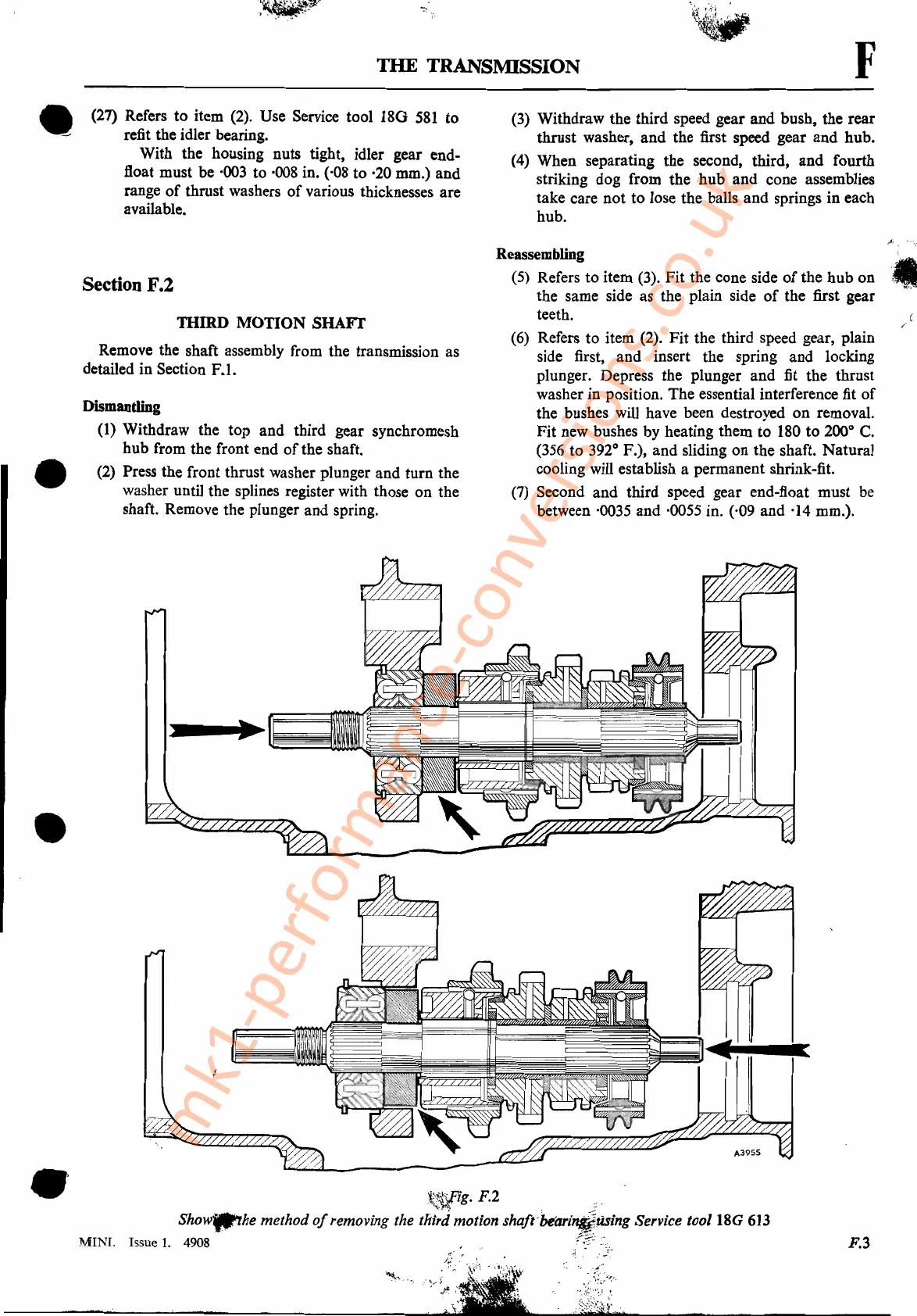

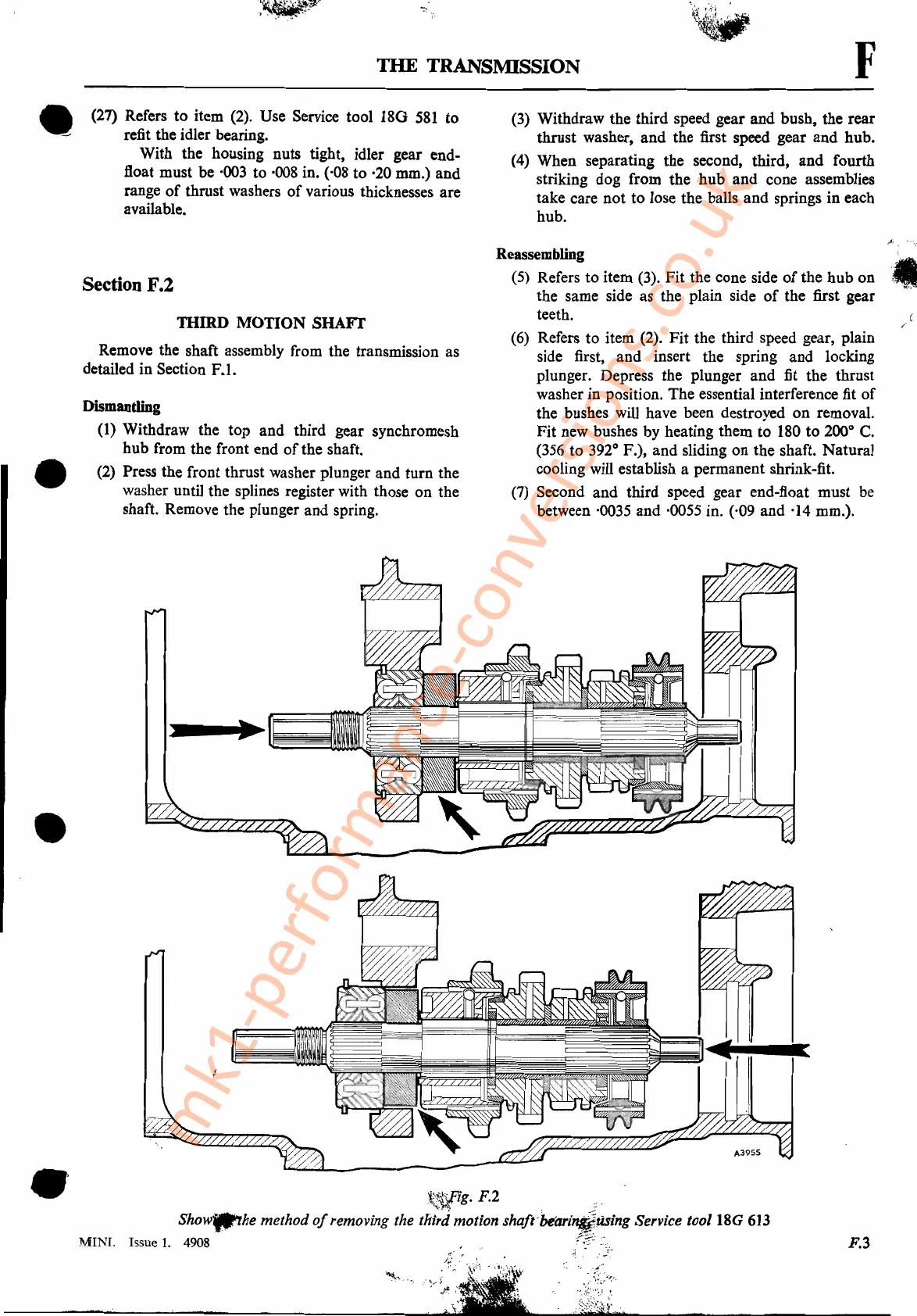

'{;~Vig.

F.2 _

Showf!l!the method

of

removing the

tJiti-d

motion shafrbearin#.using Service too1186

613

MINI.

Issue

1.

4908 .

;.-,~:.

::.

,~:

~

..

",",:.

.'

mk1-performance-conversions.co.uk

Loading...

Loading...