D

TIlE

FUEL SYSTEM

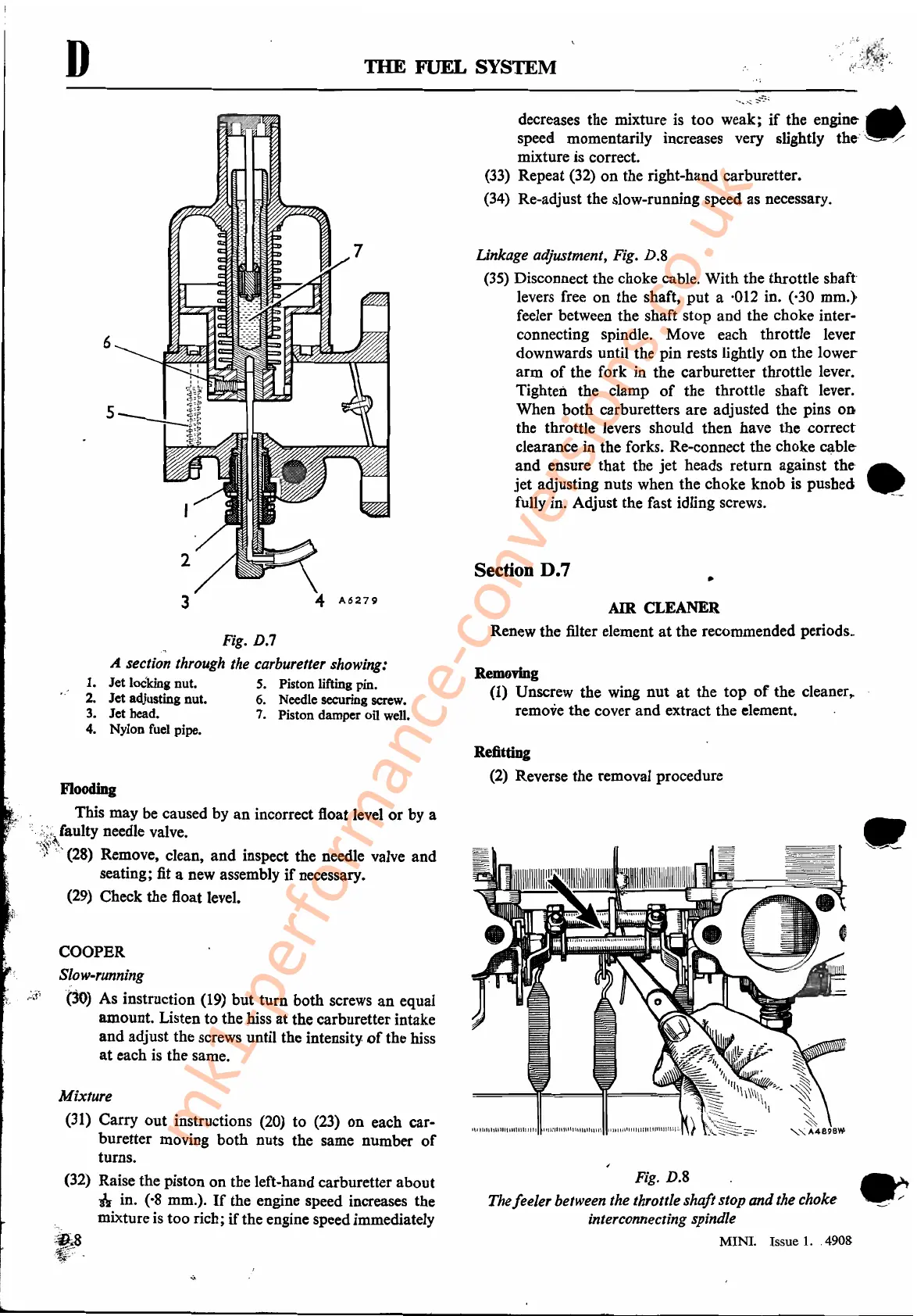

Fig. D.?

A section through the carburetter showing:

1.

Jet loekini nut. S. Piston lifting pin.

2.

Jet adjusting nut.

6.

Needle securing screw.

3.

Jet head.

7.

Piston damper oil

well.

4. Nylon

fuel

pipe.

AIR CLEANER

Renew the filter element

at

the recommended

periods~

Removing

(1) Unscrew the wing nut

at

the top

of

the cleaner,.

remove the cover and extract the element.

,.

Section D.7

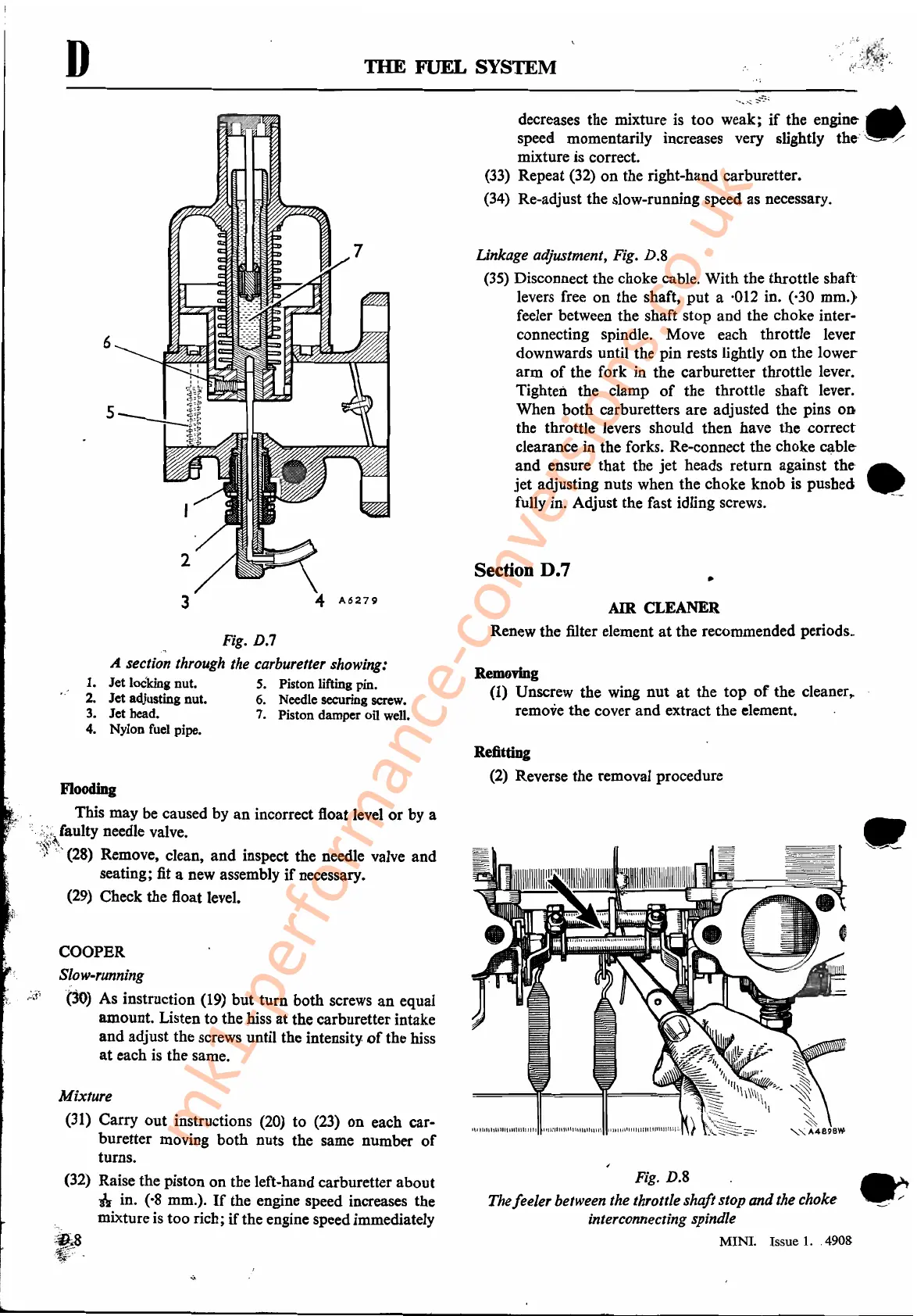

Linkage adjustment, Fig.

D.S

(35) Disconnect the choke cable. With the throttle shaft

levers free on the shaft, put a

·012 in. (·30 mm.)

feeler between the shaft stop and the choke inter-

connecting spindle. Move each throttle lever

downwards until the pin rests

lightly

on

the lower

arm

of

the fork in the carburetter throttle lever.

Tighten the clamp

of

the throttle shaft lever.

When both carburetters are adjusted the pins

OD

the throttle levers should then have the correct

clearance in the forks. Re-connect the choke

c~ble

and ensure that the jet heads return against

the

•

jet adjusting nuts when the choke knob

is

pushed .

__

fully in. Adjust the fast idling screws.

...

~

...

,.~:,,;~

decreases the mixture

is

too weak;

if

the

engine-

•

speed momentarily increases very slightly

the"·,=

Y

mixture

is

correct.

(33) Repeat (32) on the right-hand carburetter.

(34)

Re-adjust the slow-running speed as necessary.

4

A6279

3

6

Refitting

(2) Reverse the removal procedure

.'

-_._--

~

---

Fig.

D.S

Thefeeler between the throttleshaft stop

and

the choke

interconnecting spindle

MINI. Issue

1.

.4908

Mixture

(31) Carry out instructions (20) to (23) on each car-

buretter moving both nuts the same number

of

turns.

(32) Raise the piston on the left-hand carburetter about

if

in. (-8 mm.).

If

the engine speed increases the

mixture

is

too rich;

if

the engine speed immediately

:~;.8

~:

Flooding

This may be caused by' an incorrect float level or by a

':,'::,;;.:).1

aulty needle valve.

'':t~\''':\

.\-'

"(28)

Remove, clean, and inspect the needle valve and

seating;

fit

a

new

assembly

if

necessary.

(29) Check the float level.

COOPER

SJow-running

,~d'.

'(30)

·As instruction

(19)

but turn both screws an equal

amount. Listen to the hiss at the carburetter intake

and adjust the screws until the intensity

of

the hiss

at

each

is

the same.

mk1-performance-conversions.co.uk

Loading...

Loading...