THE

FUEL SYSTEM

D

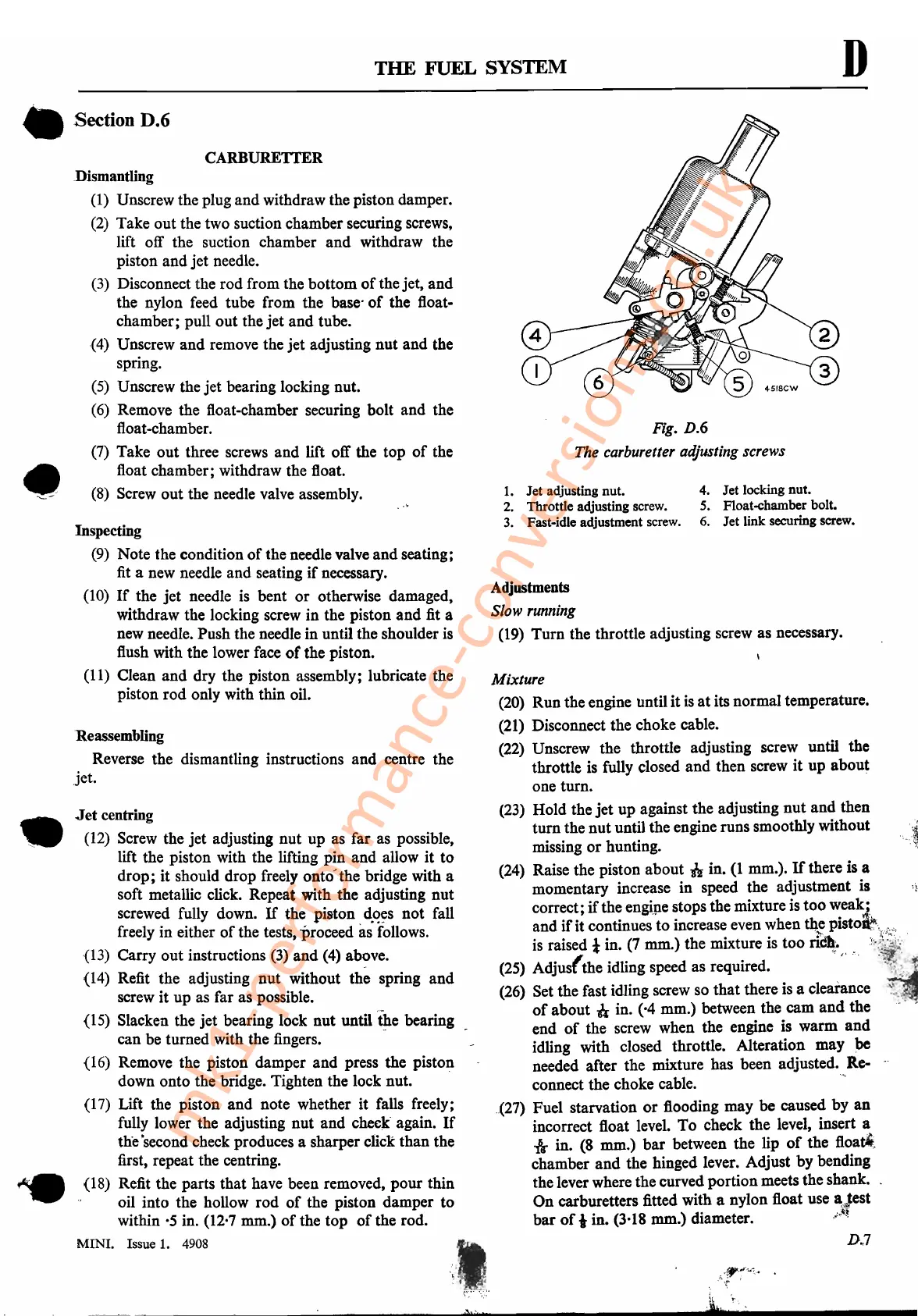

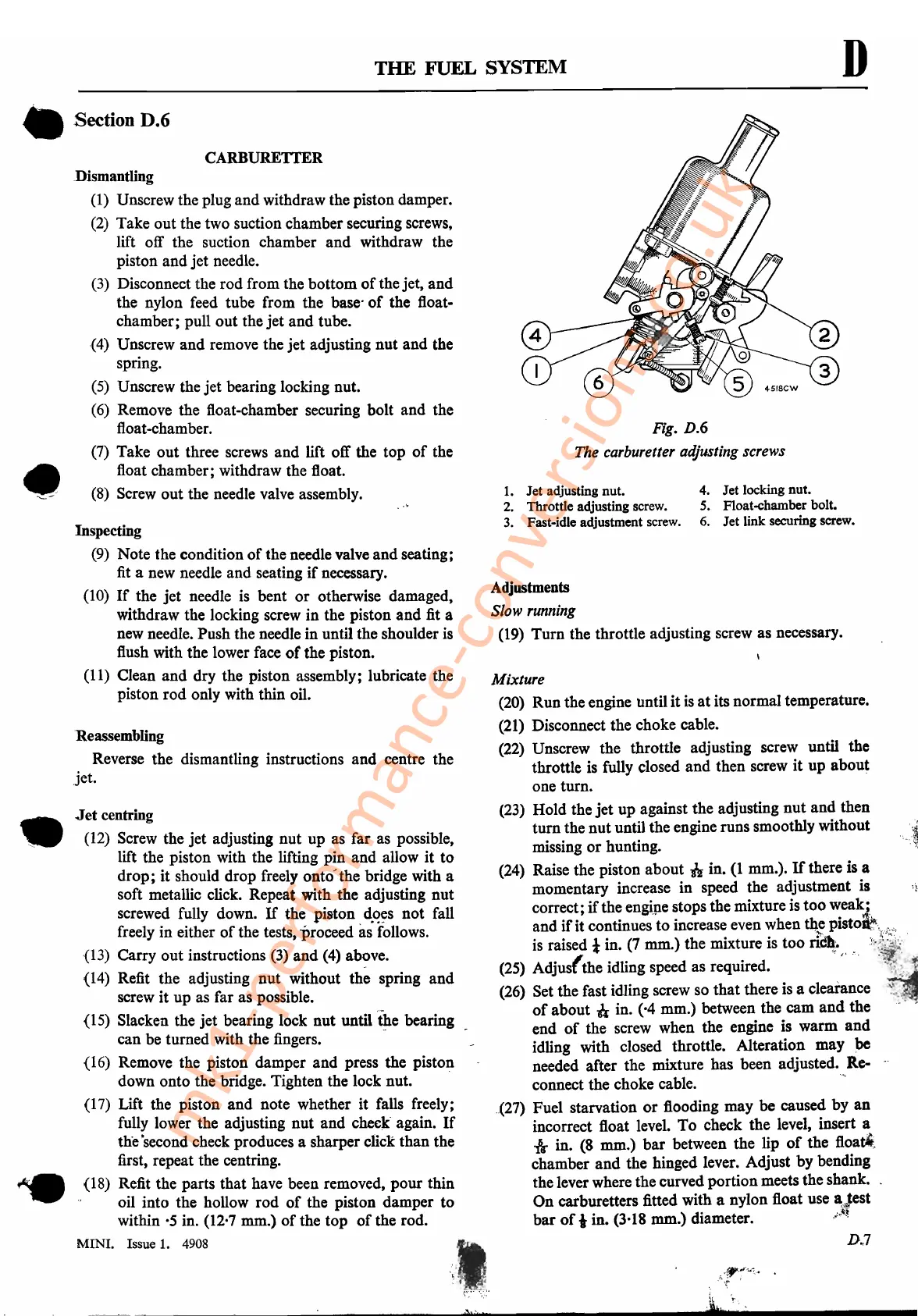

4. Jet locking

nut.

5. Float-chamber bolt.

6.

Jet link securing screw.

1.

Jet adjusting nut.

2. Throttle adjusting screw.

3.

Fast-idle adjustment screw.

I,f,'r---"

\,

'"

':

'

'M

Fig. D.6

The carburetter adjusting screws

Mixture

(20) Run the engine until

it

is

at

its normal temperature.

(21) Disconnect the choke cable.

(22) Unscrew the throttle adjusting screw until the

throttle is fully closed

and

then screw

it

up about

one turn.

(23) Hold the

jet

up against the adjusting

nut

and then

turn the nut until the engine runs smoothly without

missing

or

hunting.

(24) Raise the piston about

if

in.

(1

mm.).

If

there is a

momentary increase in speed the adjustment is

correct;

if

the engipe stops the mixture is

too

weak""

and

if

it continues to increase even when

th.e

pist01\~"c;,,,

is

raised 1in. (7 mm.) the mixture is too

ri~.

:~{~<"'\

(25) Adjus(the idling speed as required. .

(26) Set the fast idling screw so that there is a clearance

of

about n in. ('4 mm.) between the cam

and

the

end

of

the screw when the engine is warm

and

idling with closed throttle. Alteration may

pe

needed after the mixture has been adjusted.

R.e-

connect the choke cable.

'"

.(27) Fuel starvation

or

flooding may be caused by

an

incorrect float level.

To

check the level, insert a

*in. (8 mm.)

bar

between the lip

of

the floati,

chamber

and

the hinged lever. Adjust by bending

the lever where the curved portion meets the shank.

On

carburetters fitted with a nylon float use a:Jest

bar

of

i in. (3,18 mm.)

diameter.!l~

D.,7

Adjustments

Slow running

(19)

Turn the throttle adjusting screw as necessary.

CARBURETTER

Inspecting

(9)

Note the condition

of

the needle valve and seating;

fit a new needle and seating

if

necessary.

(10)

If

the

jet

needle is bent

or

otherwise

damaged~

withdraw the locking screw in the piston and fit a

new needle. Push the needle in until the shoulder

is

flush with the lower face

of

the piston.

(11) Clean

and

dry the piston assembly; lubricate the

piston

rod

only with thin oil.

Jet

centring

(12)

Screw the

jet

adjusting

nut

up as far as possible,

lift the piston with the lifting pin and allow

it

to

drop;

it

should drop freely onto

J

the bridge with a

soft metallic click. Repeat with the adjusting

nut

screwed fully down.

If

the. piston.

d.,?~s

not fall

freely in either

of

the tests, 'proceed as follows.

(13) Carry out instructions (3) and (4) above.

(14) Refit the adjusting nut without the spring and

screw it up as far as possible.

(IS) Slacken the

jet

bearing lock nut untiltl.te bearing

can be turned with the fingers.

(16) Remove the piston damper and press the piston

down onto the bridge. Tighten the lock nut.

(17) Lift the piston

and

note whether it falls freely;

fully lower the adjusting nut

and

check again.

If

th'e

'second check produces a sharper click than the

first, repeat the centring.

(18) Refit the parts that have been removed,

pour

thin

oil into the hollow

rod

of

the piston damper to

within

'5

in. (12'7 mm.)

of

the top

of

the rod.

MINI.

Issue 1. 4908

Dismantling

(1)

Unscrew the plug

and

withdraw the piston damper.

(2) Take out the two suction chamber securing screws,

lift off the suction chamber

and

withdraw the

piston and jet needle.

(3) Disconnect the rod from the bottom

of

the jet,

and

the nylon feed tube from the base·

of

the float-

chamber; pull out the

jet

and tube.

(4) Unscrew and remove the jet adjusting nut and the

spring.

(5) Unscrew the

jet

bearing locking nut.

(6) Remove the float-chamber securing bolt and the

float-chamber.

(7) Take out three screws and lift off the top

of

the

float chamber; withdraw the float.

(8) Screw out the needle valve assembly.

Reassembling

Reverse the dismantling instructions and centre the

jet.

• Section D.6

•

'---

•

mk1-performance-conversions.co.uk

Loading...

Loading...