THE

ENGINE

•

•

•

•

Refitting

(7) Reverse the removal instructions.

NOTES.-Pull

the gear lever

up

into the interior

of the car before the engine is lowered into position.

Keep

the sliding joints pushed

well

onto the drive

shaft splines

while

the flexible couplings are

moved

into position.

COOPER

Removing

(1)

Carry out the instructions

(1)

to

(10)

and

(15)

in

Section A.I2.

(2)

Remove the fresh-air motor (when fitted).

(3) Disconnect the oil gauge pipe.

(4) Take offthe distributor cap.

(5) Remove the carburetters and air cleaners (Sections

A.I and A.2).

(6) Remove the exhaust pipe assembly (Section A.3).

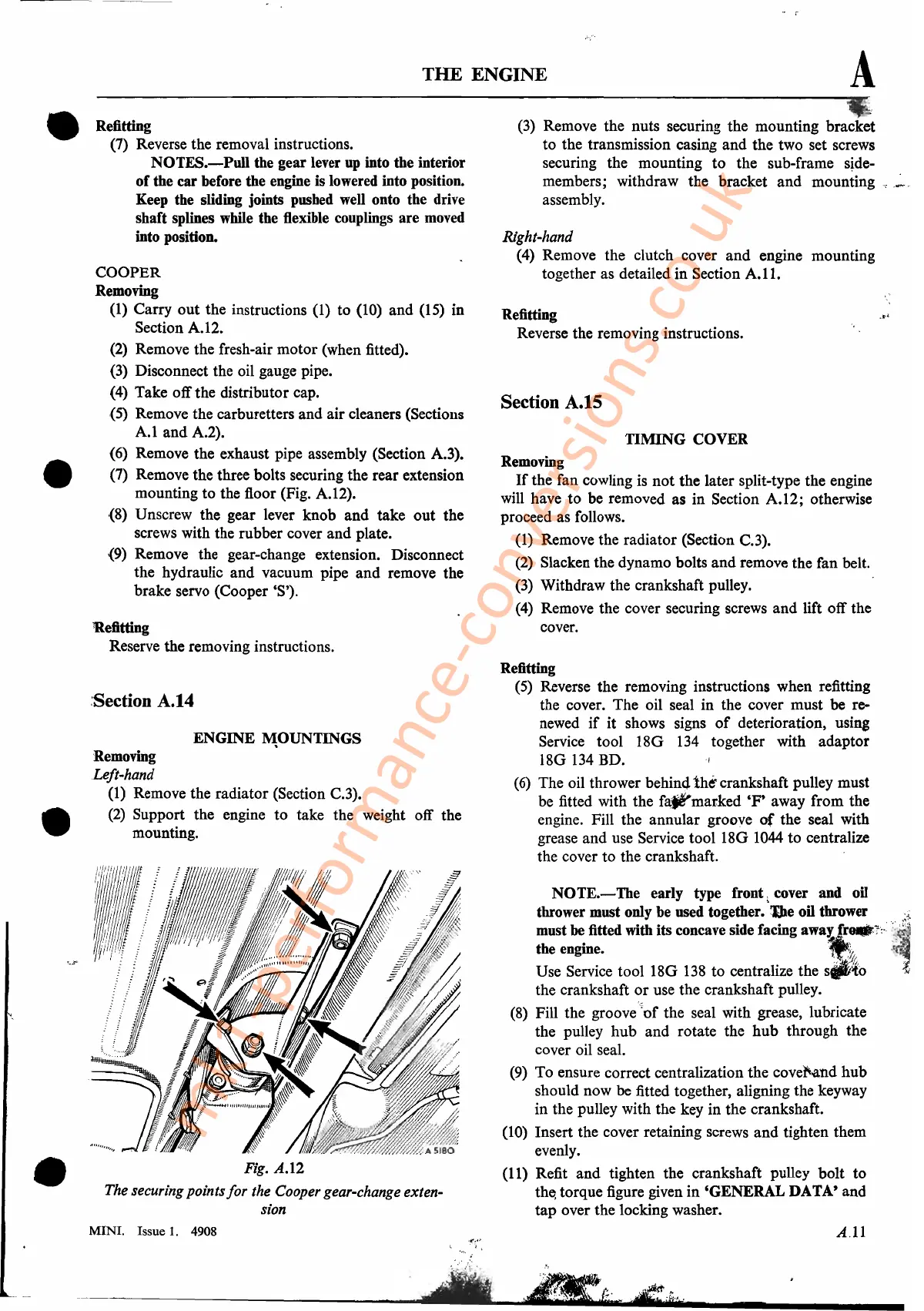

(7) Remove the three bolts securing the rear extension

mounting to the floor (Fig. A.I2).

(8) Unscrew the gear lever knob and take out the

screws with the rubber cover and plate.

(9) Remove the gear-change extension. Disconnect

the hydraulic and vacuum pipe and remove the

brake servo (Cooper'S').

Refitting

Reserve the removing instructions.

:Section A.14

ENGINE

~OUNTINGS

Removing

Left-hand

(l)

Remove the radiator (Section C.3).

(2)

Support the engine to take the weight off the

mounting.

11'

Fig.

A.l2

The securing points

for

the Cooper gear-change exten-

sion

MINI. Issue

1.

4908

A

_.

(3)

Remove the nuts securing the mounting bracket

to the transmission casing and the two set screws

securing the mounting

to

the sub-frame sjde-

members; withdraw the bracket and mounting

_,"'-','

assembly.

Right-hand

(4) Remove the clutch cover

and

engine mounting

together as detailed in Section

A.II.

Refitting

Reverse the removing instructions.

Section A.1S

TIMING COVER

Removing

If

the fan cowling is not the later split-type the engine

will have to be removed as in Section A.12; otherwise

proceed as follows.

(1) Remove the radiator (Section C.3).

(2)

Slacken the dynamo bolts and remove the fan belt.

(3)

Withdraw the crankshaft pulley.

(4)

Remove the cover securing screws and lift off the

cover.

Refitting

(5)

Reverse the removing instructions when refitting

the cover. The oil seal in the cover must be re-

newed

if

it shows signs

of

deterioration, .usins

Service tool 18G

134

together with adaptor

18G

134

BD.

(6)

The oil thrower

behin41ht

crankshaft pulley must

be fitted with the

fa,~marked

'F'

away from the

engine. Fill the annular groove

of

the seal with

grease and use Service

tool18G

1044

to centralize

the cover to the crankshaft. .

NOTE.-Tbe

early type front

~

cover and oil

thrower must only

be

used together.

~e

oil thrower

,:~

must be fitted with its concave side facing

away:

fr_1'::';~;

the

engine.l!k..

":,:

Use Service

tool18G

138

to centralize the

s_to

;~

the crankshaft

or

use the crankshaft pulley.

(8)

Fill the groove

'~of

the seal with grease, lubricate

the pulley hub and rotate the

hub

through the

cover oil seal.

(9)

To ensure correct centralization the covel'.a,nd hub

should now be fitted together, aligning the keyway

in the pulley with the key in the crankshaft.

Cl

0)

Insert the cover retaining screws and tighten them

evenly.

(11) Refit and tighten the crankshaft' pulley bolt to

the,

torque figure given in 'GENERAL DATA' and

tap over the locking washer.

A.11

mk1-performance-conversions.co.uk

Loading...

Loading...