THE ENGINE

Aa

A6746B

Aa.9

3

____

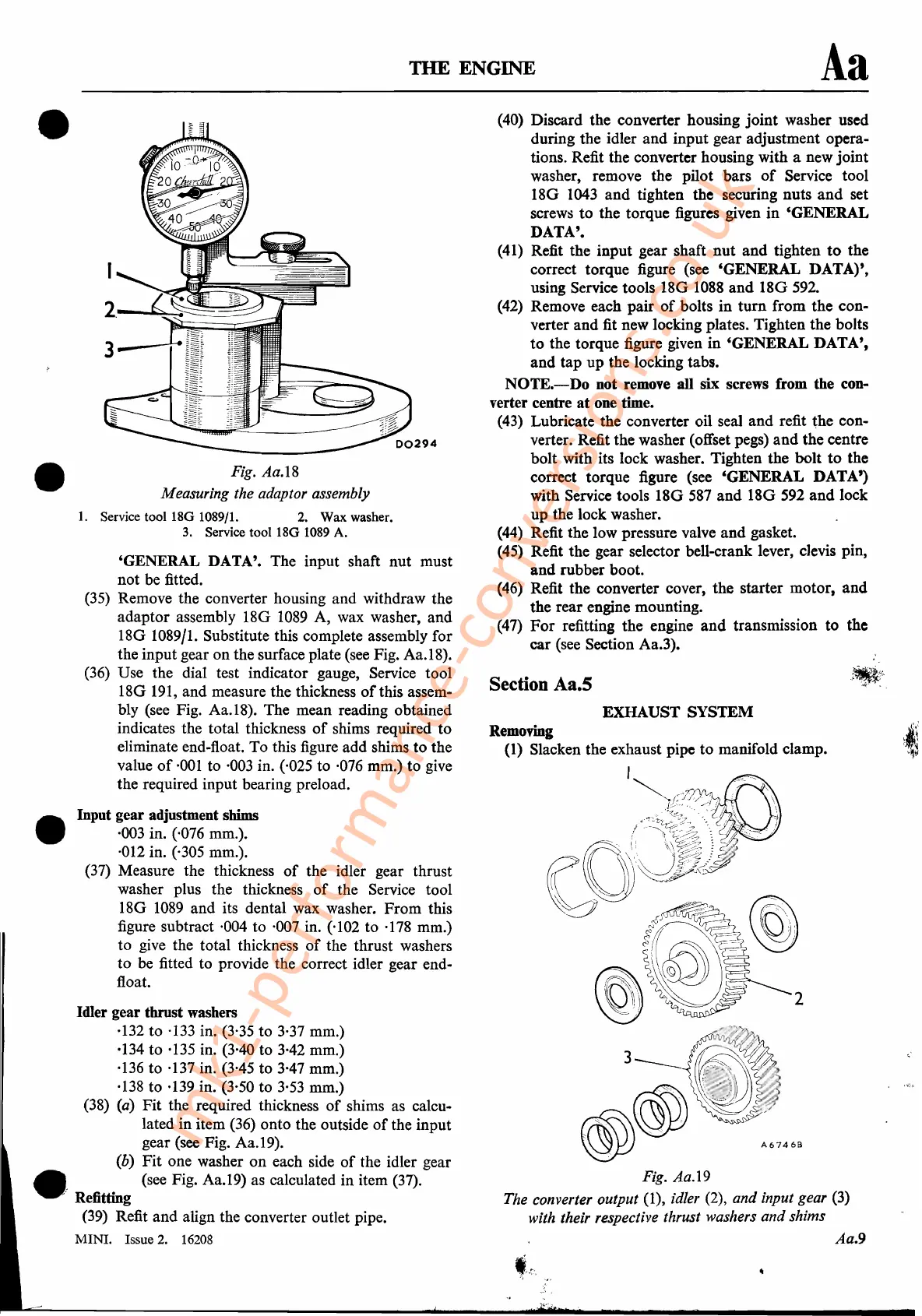

Fig. Aa.19

The converter output

(1), idler (2), and input gear (3)

with their respective thrust washers and shims

(40) Discard the converter housing

joint

washer used

during the idler and input gear adjustment opera-

tions. Refit the converter housing with a new joint

washer, remove the pilot bars

of

Service tool

18G

1043

and

tighten the securing nuts

and

set

screws

to

the torque figures given

in

'GENERAL

DATA'.

(41) Refit the input gear shaft

nut

and

tighten

to

the

correct torque figure (see 'GENERAL DATA)',

using Service tools

180

1088

and

180592.

(42) Remove each pair

of

bolts

in

turn

from the con-

verter and fit new locking plates. Tighten the bolts

to

the torque figure given

in

'GENERAL DATA',

and

tap

up

the locking tabs.

NOTE.-Do

not remove all six screws from the con-

verter centre

at

one time.

(43) Lubricate the converter oil seal

and

refit the con-

verter. Refit the washer (offset pegs)

and

the centre

bolt with its lock washer. Tighten the bolt

to

the

correct torque figure (see 'GENERAL DATA')

with Service tools

180

587

and

180

592

and

lock

up

the lock washer.

(44) Refit the low pressure valve

and

gasket.

(45) Refit the gear selector bell-crank lever, clevis pin,

and

rubber boot.

(46) Refit the converter cover, the starter motor,

and

the rear engine mounting.

(47)

For

refitting the engine

and

transmission to the

car (see Section Aa.3).

EXHAUST SYSTEM

Removing

(1) Slacken the exhaust pipe

to

manifold clamp.

I

;P._.~

~~/;:7J{jll!.

,...

..

\

("~~~~~u

I/;,'k;

Section Aa.5

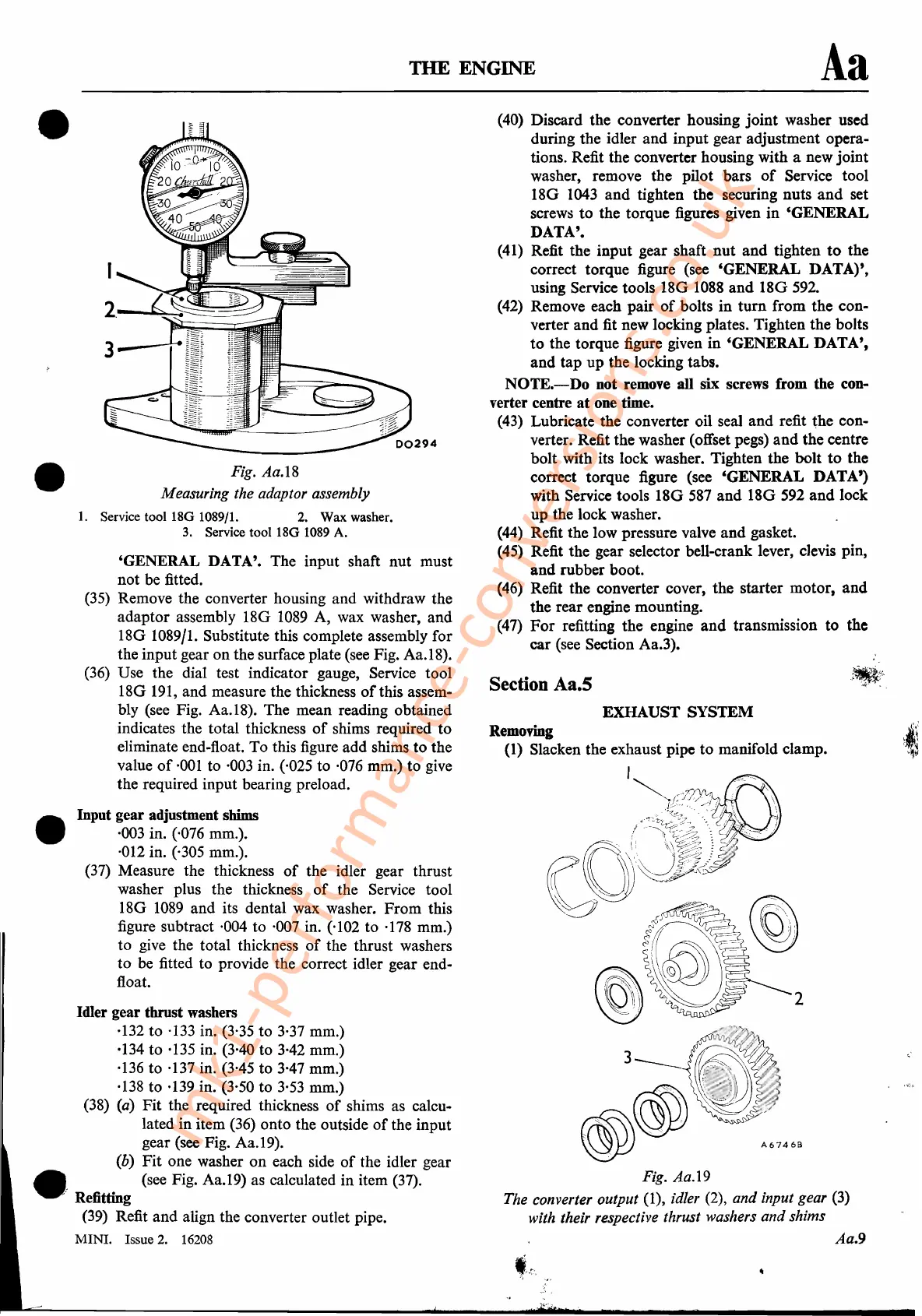

Fig. Aa.18

Measuring the adaptor assembly

1.

Service tool 18G 1089/1. 2. Wax washer.

3. Service

tool18G

1089

A.

'GENERAL DATA'. The input shaft

nut

must

not be fitted.

(35)

Remove the converter housing and withdraw the

adaptor assembly 18G

1089

A, wax washer, and

180

1089/1. Substitute this complete assembly for

the input gear on the surface plate (see Fig. Aa.18).

(36) Use the dial test indicator gauge, Service tool

18G

191,

and measure the thickness

of

this assem-

bly (see Fig. Aa.18). The mean reading obtained

indicates the total thickness

of

shims required

to

eliminate end-float. To this figure add shims

to

the

value

of

·001

to

·003

in. ('025 to ·076 mm.) to give

the required input bearing preload.

Input gear adjustment shims

·003 in. (,076 mm.).

·012 in. (,305 mm.).

(37) Measure the thickness

of

the idler gear thrust

washer plus the thickness

of

the Service tool

18G

1089

and its dental wax washer.

From

this

figure subtract ·004 to ·007 in. ('102 to ·178 mm.)

to give the total thickness

of

the thrust washers

to

be fitted to provide the correct idler gear end-

float.

•

Idler gear thrust washers

·132

to

·133 in. (3'35 to 3·37 mm.)

·134

to

·135 in. (3'40 to 3·42 mm.)

·136 to ·137 in. (3'45 to 3'47 mm.)

·138

to ·139 in. (3,50 to 3'53 mm.)

(38)

(a)

Fit the required thickness

of

shims as calcu-

lated in item (36) onto the outside

of

the input

gear (see Fig. Aa.19).

(b)

Fit

one washer

on

each side

of

the idler gear

•

' (see Fig. Aa.19) as calculated in item (37).

, Refitting

(39) Refit

and

align the converter outlet pipe.

MINI.

Issue 2.

16208

•

•

mk1-performance-conversions.co.uk

Loading...

Loading...