THE

ENGINE

Aa

(2) Release the pipe from the bracket

on

the final

drive casing (Fig. Aa.3)

and

from the two locations

on

the rear sub-frame.

Refitting

(3) Refit the exhaust system to the car with the inter-

mediate

and

rear support clips loose

to

allow

articulation

at

the manifold spherical flange.

(4) Align

the

pipe flange with the manifold, refit

and

tighten the manifold clamp.

(5) Ensure correct alignment

of

the system

and

tighten

the remaining fixing points.

Section Aa.6

DISTRIBUTOR

DRIVING

SPINDLE

Removing

(1) Remove the distributor

and

driving spindle as

detailed

in

Section A.IO.

Refitting

(2) Refitting is described

in

Section A.IO with the

following exceptions.

(3)

To

rotate the crankshaft, insert a screwdriver

through the aperture (adjacent the oil dipstick)

on

the converter housing,

and

turn

the converter

starter ring gear

to

the position described

in

Section A.lO.

(4) Check

that

the 1/4 timing

mark

on

the converter

is

in

line with the pointer

on

the converter housing

(Fig. Ba.1).

Section Aa.7

VALVE

TIMING

(1) Follow the instructions given in Section

A.I?

with

the following exceptions.

(2)

Rotate

the crankshaft as described

in

Se6tion Aa.6

until the 5°

B.T.D.e.

timing

mark

on

the con-

verter is opposite the pointer

on

the converter

cover.

Section Aa.8

OIL

PUMP

Removing

(1) Remove the engine and transmission as detailed

in

Section Aa.3.

(2)

Remove the converter

and

converter housing as

detailed

in

Section AaA, items (3)

to

(12).

(3) Remove the

pump

securing screws

and

withdraw

h.

."

the. pump.

Dismantling and reassembling

(4) Follow the instructions given in Section A.22 for

the Hobourn-Eaton pump.

Refitting

(5) Reverse the removal instructions fitting new

joint

washers as required.

Aa.IO

•

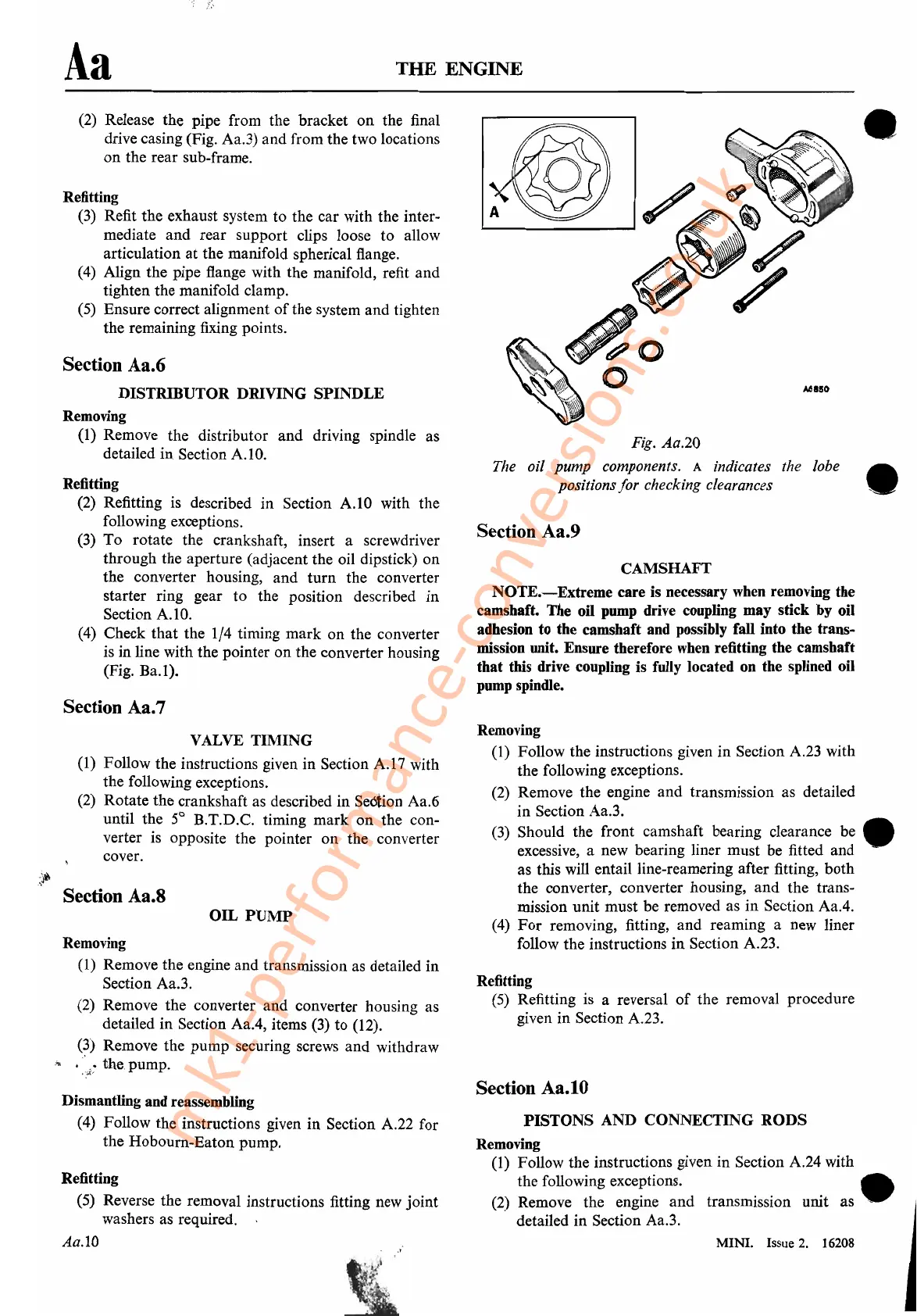

Fig. Aa.20

The oil pump components.

A indicates the lobe •

positions

for

checking clearances _ .

Section Aa.9

CAMSHAFT

NOTE.-Extreme

care is necessary when removing the

camshaft. The oil pump drive coupling may stick by oil

adhesion to the camshaft and possibly fall into the trans-

mission unit. Ensure therefore when refitting the camshaft

that

this drive coupling is fully located on the splined oil

pump spindle.

Removing

(1) Follow the instructions given

in

Section A.23 with

the following exceptions.

(2) Remove the engine

and

transmission as detailed

in Section Aa.3.

(3) Should the front camshaft bearing clearance be •

excessive, a new bearing liner must be fitted

and

as this will entailline-reamering after fitting,

both

the converter, converter housing,

and

the

trans-

mission

unit

must

be removed as

in

Section AaA.

(4)

For

removing, fitting,

and

reaming a new liner

follow the instructions

in

Section A.23.

Refitting

(5) Refitting is a reversal

of

the removal procedure

given in Section A.23.

Section Aa.tO

PISTONS

AND

CONNECTING

RODS

Removing

(1) Follow the instructions given

in

Section A.24 with

the following exceptions. •

(2) Remove the engine

and

transmission

unit

as

.-

detailed

in

Section Aa.3.

MINI. Issue

2.

16208

mk1-performance-conversions.co.uk

Loading...

Loading...