Aa

THE

ENGINE

Fig.

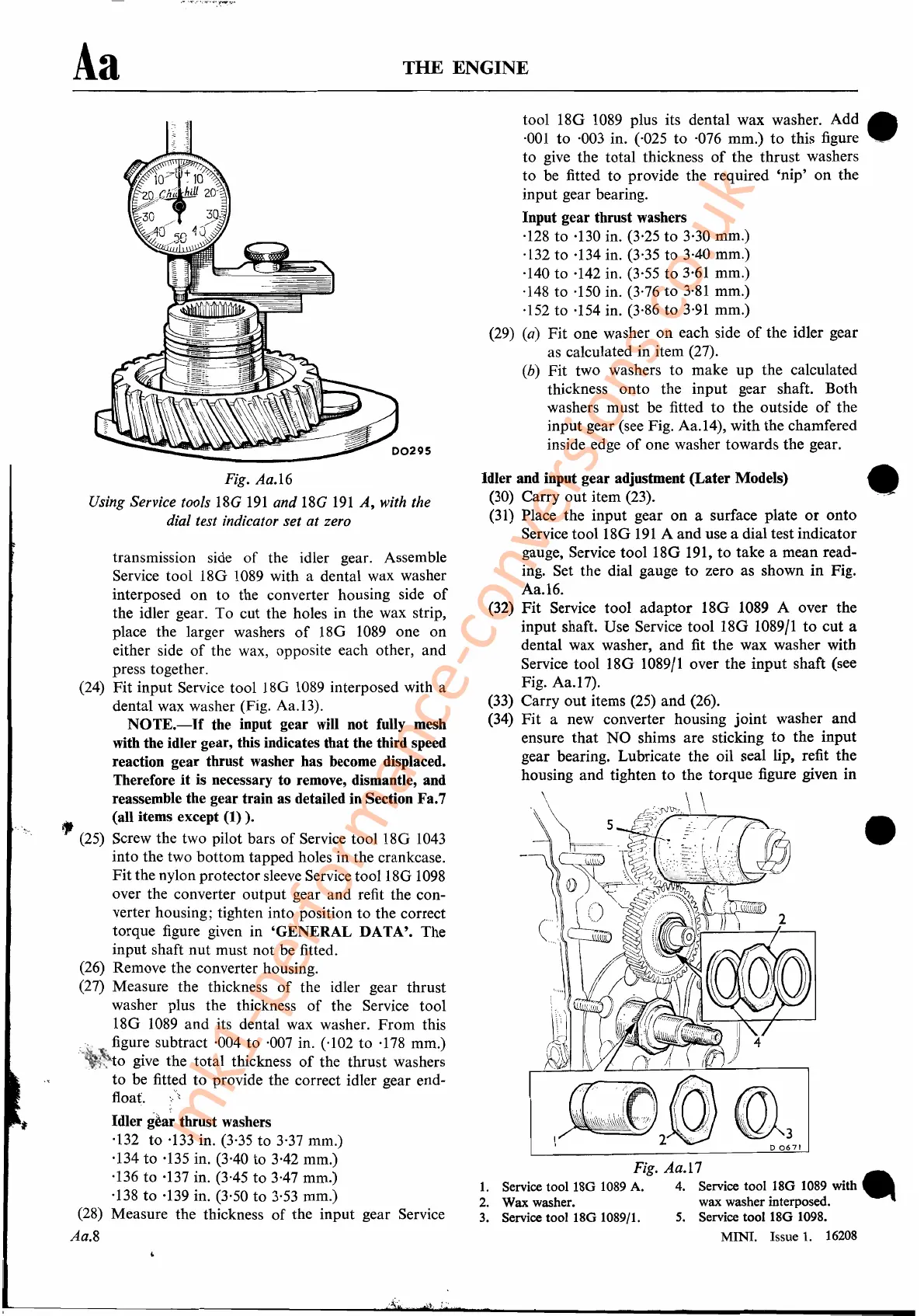

Aa.I7

1.

Service tool 18G 1089 A. 4. Service tool 18G 1089 with

•..

2. Wax washer. wax washer interposed.

3. Service tool 18G 1089/1.

5.

Service tool 18G 1098.

MINI. Issue

1.

16208

tool 18G

1089

plus its dental wax washer.

Add.

·001

to ·003 in. (,025 to ·076 mm.)

to

this figure '_

to give the total thickness

of

the thrust washers

to be fitted to provide the required

'nip'

on

the

input gear bearing.

Input gear thrust washers

·128 to ·130 in. (3,25 to 3·30 mm.)

·132

to

·134 in. (3,35

to

3·40 mm.)

·140 to ·142 in. (3,55 to

3·61

mm.)

·148 to ·150 in. (3,76 to

3·81

mm.)

·152 to ·154 in. (3,86 to

3·91

mm.)

(29)

(a)

Fit

one washer

on

each side

of

the idler gear

as calculated in item (27).

(b)

Fit

two washers to make

up

the calculated

thickness onto the input gear shaft. Both

washers must be fitted

to

the outside

of

the

input gear (see Fig. Aa.14), with the chamfered

inside edge

of

one washer towards the gear.

•

•

Idler and input gear adjustment (Later Models)

(30) Carry

out

item (23).

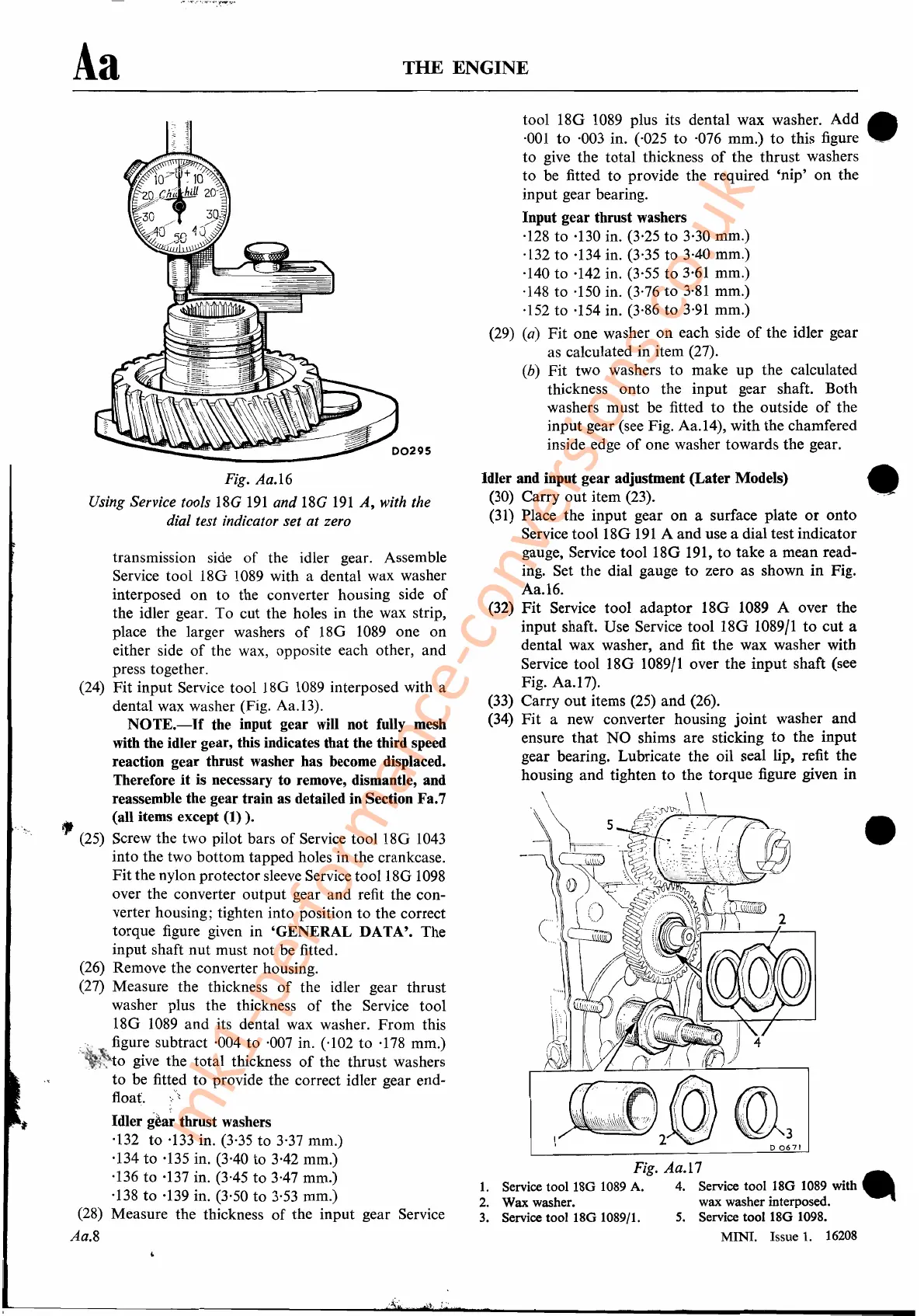

(31) Place the input gear

on

a surface plate

or

onto

Service too118G

191

A and use a dial test indicator

gauge, Service tool 18G 191,

to

take a mean read-

ing. Set the dial gauge to zero as shown

in

Fig.

Aa.16.

(32)

Fit

Service tool

adaptor

18G 1089 A over the

input shaft. Use Service tool 18G 1089/1

to

cut

a

dental wax washer,

and

fit the wax washer with

Service tool 18G 1089/1 over the input shaft (see

Fig. Aa.17).

(33) Carry

out

items (25)

and

(26).

(34)

Fit

a new converter housing

joint

washer

and

ensure

that

NO

shims are sticking

to

the input

gear bearing. Lubricate the oil seal lip, refit the

housing and tighten

to

the torque figure given in

.~

\~

~)-vvr,

\ \

, 5

_?}J

- /

C'

-

~

-l~

-1~

:

..

:;:\)1

(\

fJ

~

~

)~~~~.\~~\~.b

-

\

(~q~\~

/00

(~l1C

~,~{~)

4

~!U1()/1

.

~2003

D

0671

Fig. Aa.16

Using Service tools

18G

191

and 18G

191

A,

with the

dial test indicator set at zero

transmission side

of

the idler gear. Assemble

Service tool 18G

1089

with a dental wax washer

interposed

on

to the converter housing side

of

the idler gear. To cut the holes in the wax strip,

place the larger washers

of

18G

1089

one on

either side

of

the wax, opposite each other, and

press together.

(24)

Fit

input Service tool 18G

1089

interposed with a

dental wax washer (Fig. Aa.13).

NOTE.-If

the input gear will not fully mesh

with the idler gear, this indicates that the third speed

reaction gear thrust washer has become displaced.

Therefore

it

is necessary to remove, dismantle, and

reassemble the gear train as detailed in Section Fa.7

1f/t

(all items except

(1)

).

(25)

Screw the two pilot bars

of

Service tool 18G

1043

into the two bottom tapped holes in the crankcase.

Fit

the nylon protector sleeve Service

tool18G

1098

over the converter output gear and refit the con-

verter housing; tighten into position to the correct

torque figure given in

'GENERAL DATA'. The

input shaft nut must not be fitted.

(26)

Remove the converter housing.

(27) Measure the thickness

of

the idler gear thrust

washer plus the thickness

of

the Service tool

18G

1089

and

its dental wax washer.

From

this

;;.:'/,

'.

figure subtract ·004 to ·007 in. ('102 to

·178

mm.)

~~~),to

give the total thickness

of

the thrust washers

to

be fitted to provide the correct idler gear end-

float. .

Idlerg~ar

thrust washers

·132 to

·133

in. (3,35 to 3·37 mm.)

·134

to

·135 in. (3'40 to 3·42 mm.)

·136 to ·137 in. (3'45 to 3·47 mm.)

·138

to

·139 in. (3,50 to 3·53 mm.)

(28)

Measure the thickness

of

the input gear Service

Aa.8

\}.

;

..

mk1-performance-conversions.co.uk

Loading...

Loading...