A

Use

washer thickness

·125

to

·127 in.

(3·17

to

3·22 mm.)

·127

to

·129 in.

(3·22

to

3·27 mm.)

·129

to

·131 in.

(3·27

to

3·32 mm.)

When gap is

·1295

to

·1315 in.

(3·27

to

3·34 mm.)

·1315

to

·1335 in.

(3·34

to

3·39 mm.)

·1335 in.

to

·1345 in.

(3·39

to

3·42 mm.)

THE ENGINE

Fig.

A.16

The crankshaft primary gear with lubricated bushes

must be assembled with the correct running clearance

of

between ·003 and ·006 in. (·076 and ·152 mm.).

57598

Measure the gap indicated and use the following table

to determine the correct thickness

of

the thrust washer

required to obtain this clearance

,.

...

, I

, I

, I

, I

, I

I I

I I

I I

"

, .

, ,

I I

"

, I

I I

I'

I'

/

~

f~;~~r~)

~~~-9

I I

~

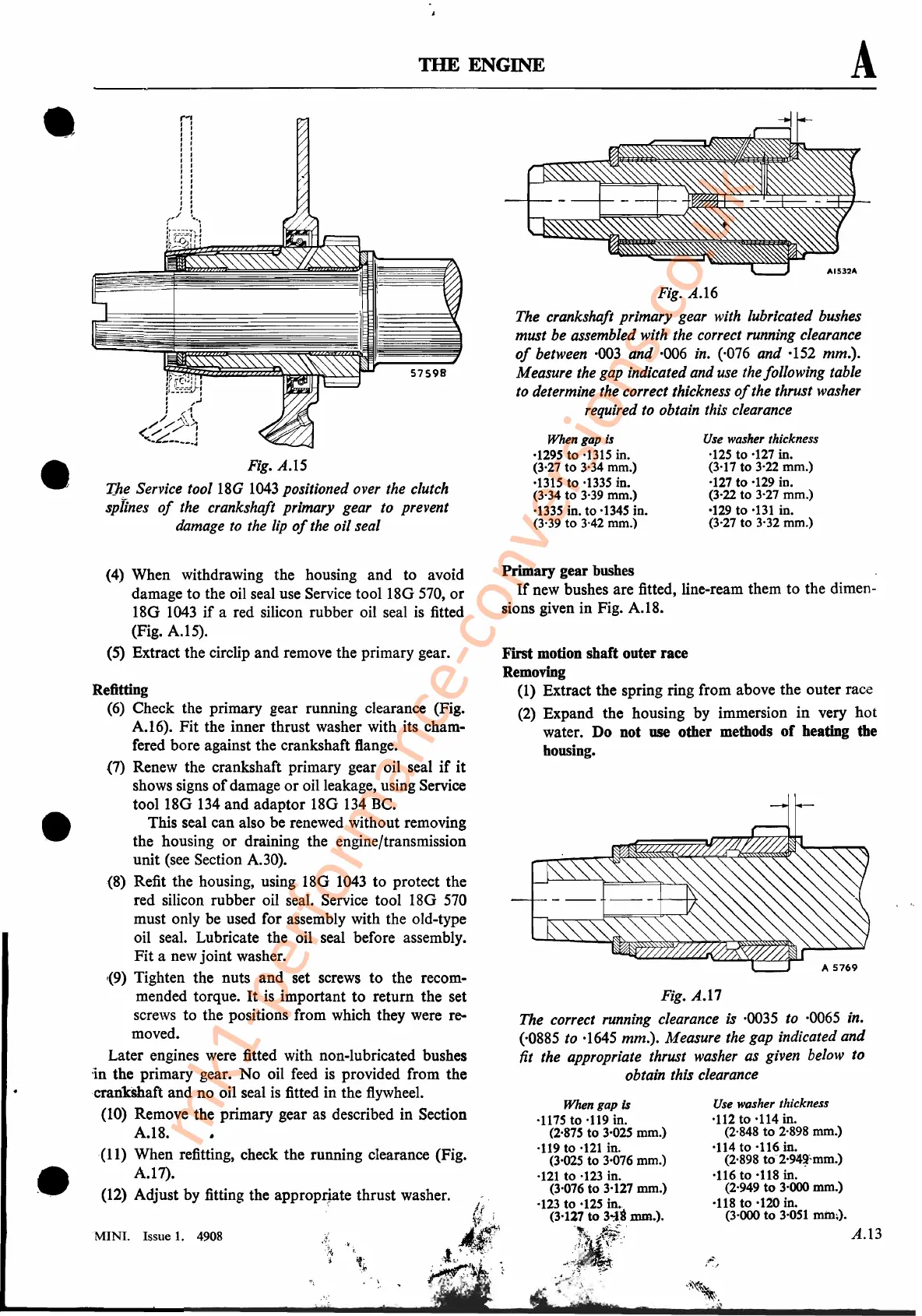

Fig. A.15

Xhe

Service tool

18G

1043 positioned over the clutch

sptines

of

the crankshaft primary gear to prevent

damage

to

the

lip

of

the oil seal

•

•

Primary gear bushes

If

new bushes are fitted, line-ream them

to

the

dimen-

sions given

in

Fig. A.18.

Use

washer thickness

·112

to

·114 in.

(2·848

to

2·898 mm.)

·114

to

·116 in.

(2·898

to2·94~~mm.)

·116

to

·118 in.

(2·949

to

3·000

mm.)

·118

to

·120 in.

(3·000

to

3·051 mm.).

A.I3

When gap is

·1175

to

·119 in.

(2·875

to

3·025 mm.)

·119

to

·121

in.

(3·025

to

3·076 mm.)

·121

to

·123 in.

(3·076

to

3·127 mm.)

·123

to

·125 in.

(3·117

to

3-:1gmm~).

~l'

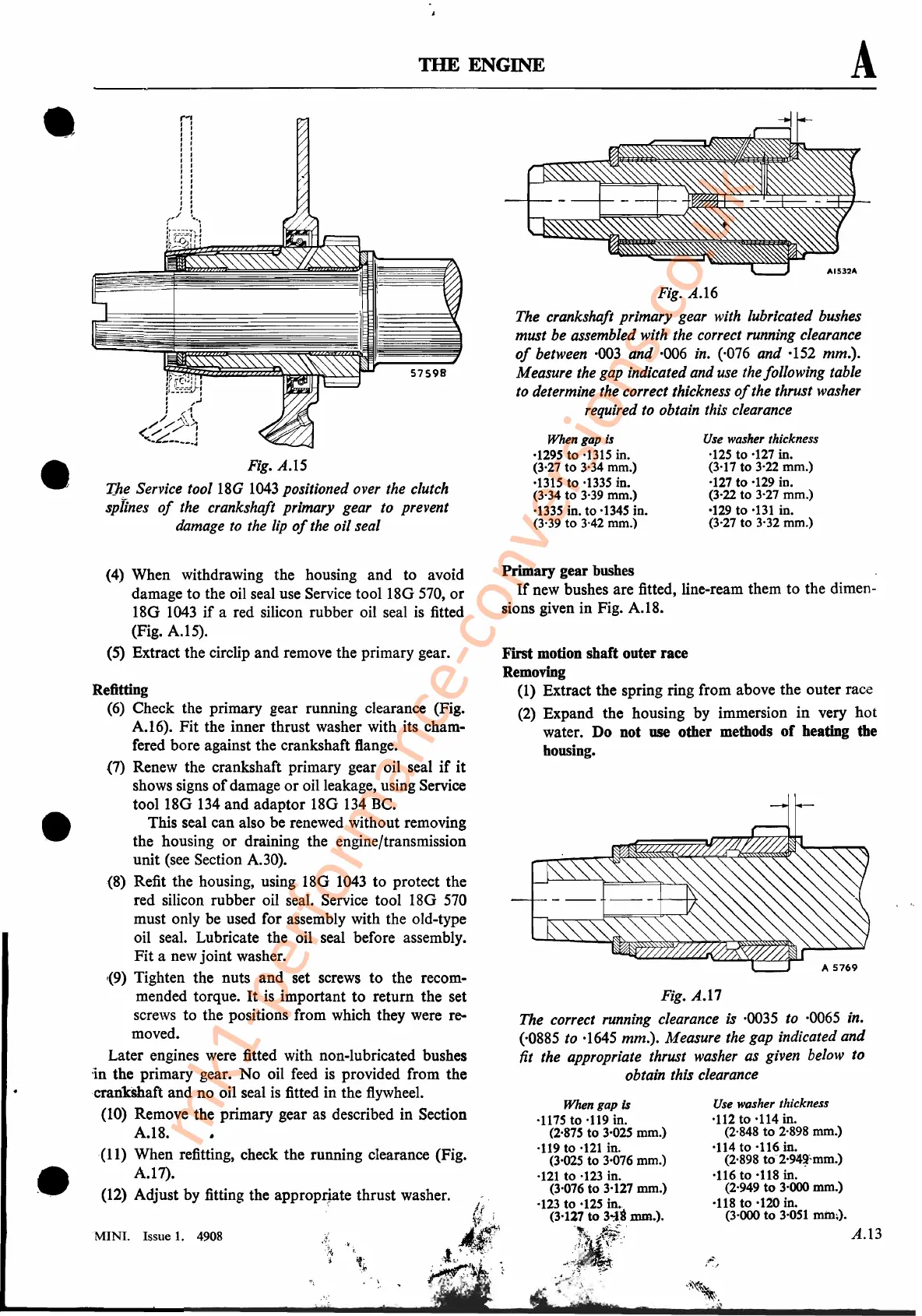

Fig. A.17

The correct running clearance is ·0035 to ·0065 in.

(·0885 to ·1645 mm.). Measure the gap indicated and

fit

the appropriate thrust washer as given below to

obtain this clearance

First motion shaft outer race

Removing

(l)

Extract

the

spring ring from above

the

outer

race

(2) Expand

the

housing

by

immersion

in

very

hot

water.

Do

not use other methods

of

heating the

housing.

(4)

When

withdrawing the housing

and

to avoid

damage

to

the oil seal use Service tool

180

570,

or

180

1043

if

a red silicon

rubber

oil seal is fitted

(Fig. A.15).

(S) Extract the circlip

and

remove the primary gear.

MINI. Issue

1.

4908

Refitting

(6) Check the primary gear running clearance (Fig.

A.16).

Fit

the inner

thrust

washer with its cham-

fered bore against

the

crankshaft flange.

(7) Renew the crankshaft primary gear oil seal

if

it

shows signs

of

damage

or

oil leakage, using Service

tool

180

134

and

adaptor

180

134 BC.

This seal

can

also be renewed without removing

the housing

or

draining the engine/transmission

unit

(see Section A.30).

(8) Refit

the

housing, using

180

1043

to

protect the

red

silicon

rubber

oil seaL Service tool

180

570

must only be used

for

assembly with the old-type

oil seal. Lubricate the oil seal before assembly.

Fit

a new

joint

washer.

{9) Tighten the

nuts

and

set screws

to

the recom-

mended torque.

It

is important

to

return

the

set

screws

to

the positions from which they were re-

moved.

Later engines were fitted with non-lubricated bushes

,in

the

primary gear.

No

oil feed is provided from

the

,crankShaft

and

no

oil seal is fitted in the flywheel.

(10) Remove the primary

gear

as described in Section

A.18.

(11)

When

refitting, check

the

running clearance (Fig.

A.I7).

(12) Adjust by fitting the

appropriate

thrust

washer. .

-

~fj

M

~·~····'·~

t'

.f

,-~,~;

"-

,~~/:~

:r;h~::il'

1',

::<':.

~~

j8;

..

.:

•

•

mk1-performance-conversions.co.uk

Loading...

Loading...