A

THE ENGINE

from the pressure spring housing. When a dia- •

phragm clutch

is

fitted, release the spring retainer '

to detach the thrust plate.

(11)

Bring Nos. 1 and 4 pistons

to

T.D.C. to prevent

the primary gear

'C'

washer from falling and being

wedged behind the flywheel. With the crankshaft

in any other position this could happen and result

in damage as the flywheel

is

withdrawn.

(12)

Tap up the locking washer

and

slacken the flywheel

retaining screw three or four threads. Use Service

tools

l8G

304 and 18G 304 M

to

free the flywheel

from the taper on the crankshaft. Remove the tool

as

soon as the flywheel

is

free.

(13)

Unscrew the flywheel retaining screws and take

off the driving washer.

(14) Withdraw the flywheel and clutch together.

(15)

Dismantle the clutch as described in

S~ction

E.l.

NOTES:

'If

•

(A)

As

the flywheel is pulled from the shaft,

01

rom

the annulus behind the flywheel oil seal may spill

down the face

of

the flywheel onto the clutch driven

plate. Look out for this when dismantling

to

avoid assuming

that

the oil has passed the seal

during normal running.

(B)

In

early engines a rubber plug was fitted into the

rear end

of

the crankshaft as

an

added precaution

against oil leaking past the normal brass taper plug.

An improved brass plug

is

nowfitted

and

the rubber

is

discontinued.

(c)

Later engines have non-lubricated bushes

in

the

crankshaft primary gear and the flywheel oil seal

is

not fitted.

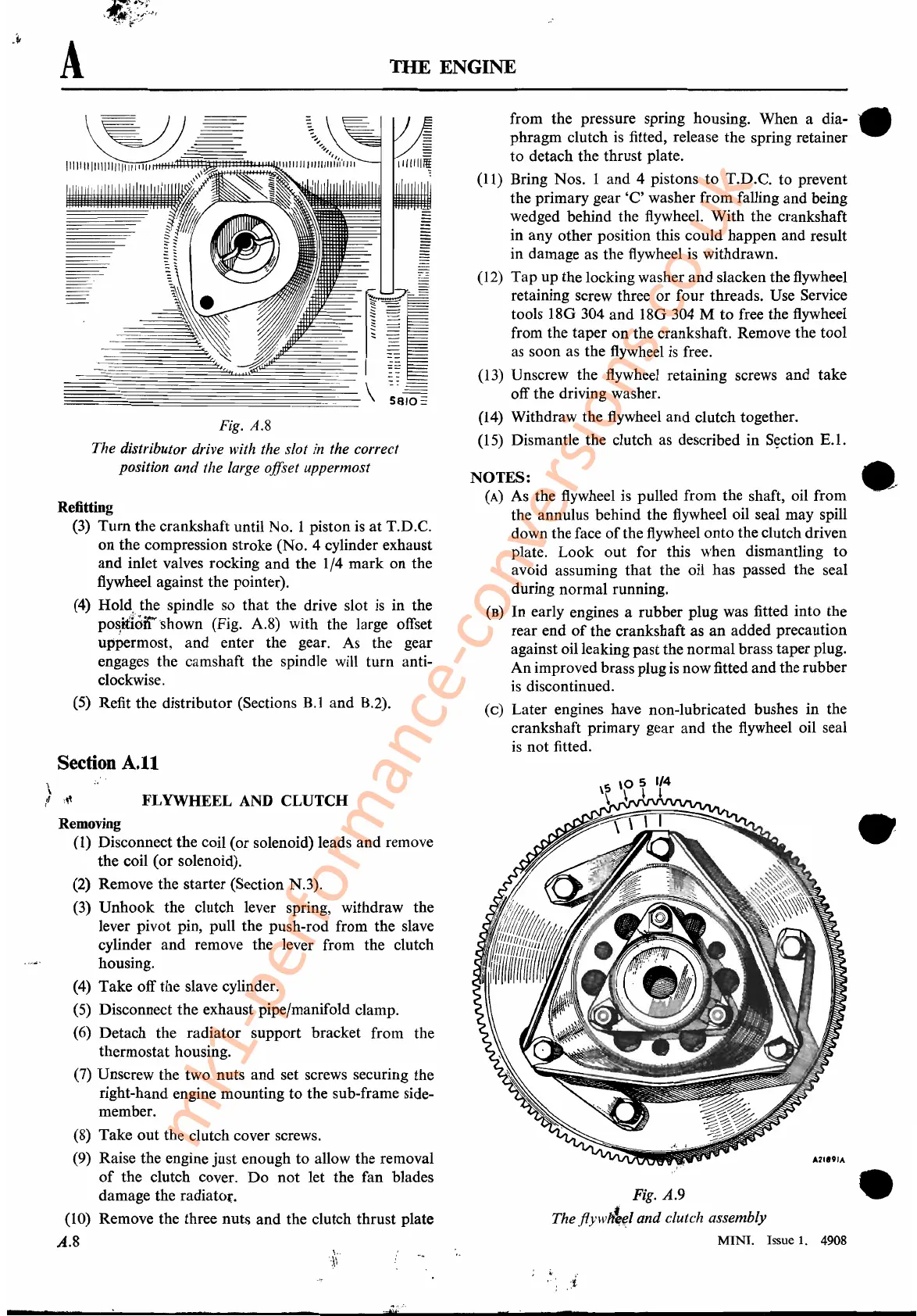

Fig.

A.8

The distributor drive with the slot

in

the correct

position and the large offset uppermost

Refitting

(3)

Turn

the crankshaft until No. 1 piston

is

at T.D.C.

on the compression stroke (No. 4 cylinder exhaust

and inlet valves rocking and the 1/4 mark on the

flywheel against the pointer).

(4)

Hold"

the spindle so that the drive slot

is

in the

po~iti6ii"shown

(Fig. A.8) with the large offset

uppermost, and enter the gear. As the gear

engages the camshaft the spindle will turn anti-

clockwise.

(5)

Refit the distributor (Sections B.l and B.2).

Section

A.tt

\ .,

,.,:~

FLYWHEEL

AND

CLUTCH

Removing

(1)

Disconnect the coil (or solenoid) leads and remove

the coil (or solenoid).

(2)

Remove the starter (Section N.3).

(3)

Unhook the clutch lever spring, withdraw the

lever pivot pin, pull the push-rod from the slave

cylinder and remove the lever from the clutch

....

,...

housing.

(4)

Take off the slave cylinder.

(5)

Disconnect the exhaustpipeJmanifold clamp.

(6) Detach the radiator support bracket from the

thermostat housing.

(7)

Unscrew the two nuts and set screws securing the

right-hand engine mounting to the sub-frame side-

member.

(8)

Take out the clutch cover screws.

(9) Raise the engine just enough to allow the removal

of

the clutch cover.

Do

not let the fan blades

damage the radiatol.'.

(10) Remove the three nuts and the clutch thrust plate

A.8

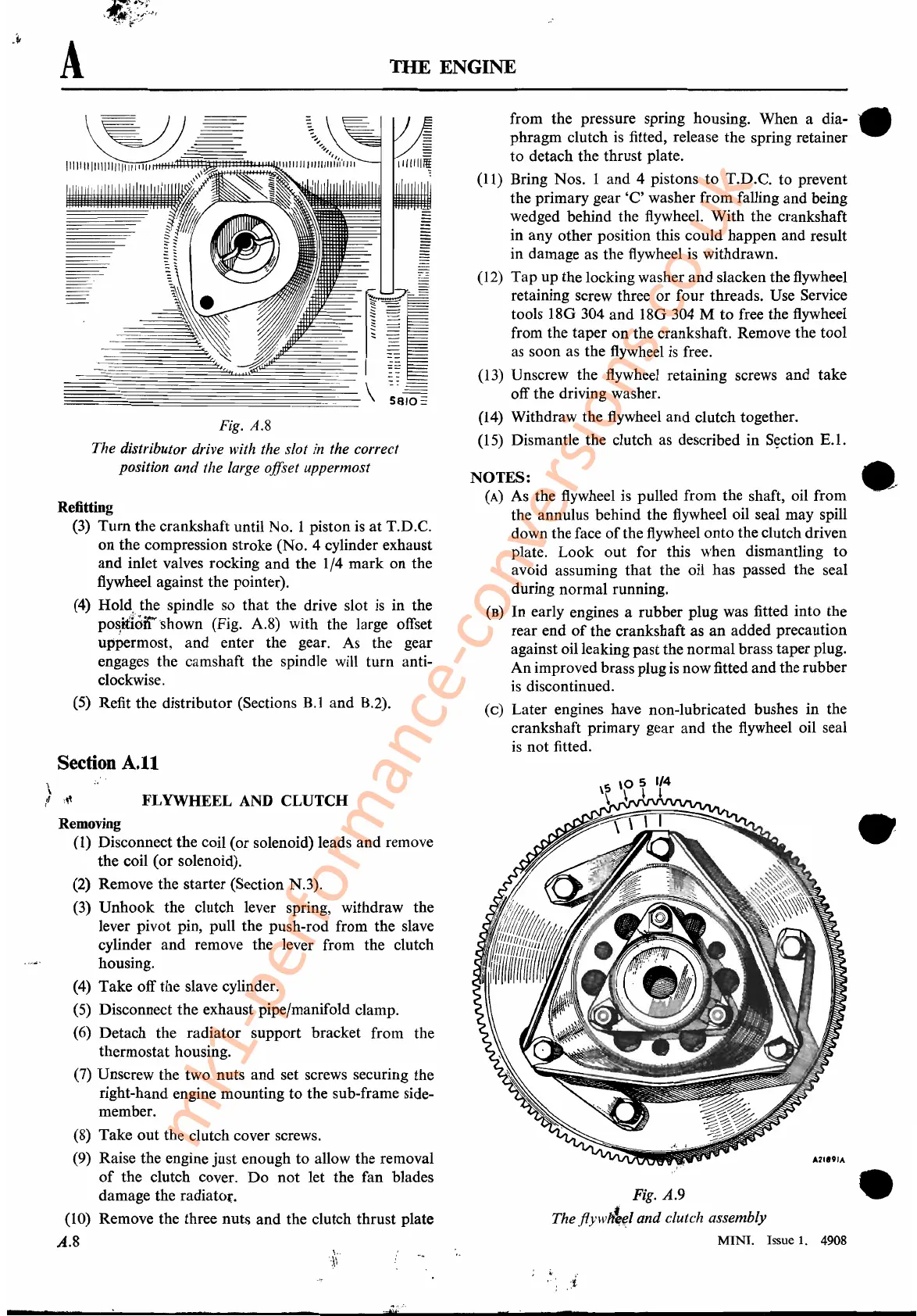

Fig. A.9

,-

The

.flyw~(JJ

and clutch assembly

MINI.

Issue

1.

4908

•

•

mk1-performance-conversions.co.uk

Loading...

Loading...