54

Manual version: 1.10 / Jan. 2011

Manual rev.: 1

Údržba stroje

Wartung /

Machine smaintenance

4.4. Cooling agents and chips disposal

The quality of the cooling

agent will deteriorate due to:

If the solution is too weak: If the solution is too strong:

• use of contaminated water

• impurity

• outside oil contamination

(hydraulics, gears)

• high operating temperatures

• lack of air circulation

• wrong concentration

corrosion protection is

diminished

• lubrication decreases

• microbial attack is more likely

• the cooling ability is decreased

• foam behaviour increases

• emulsions stability deteriorates

• sticky residue develops

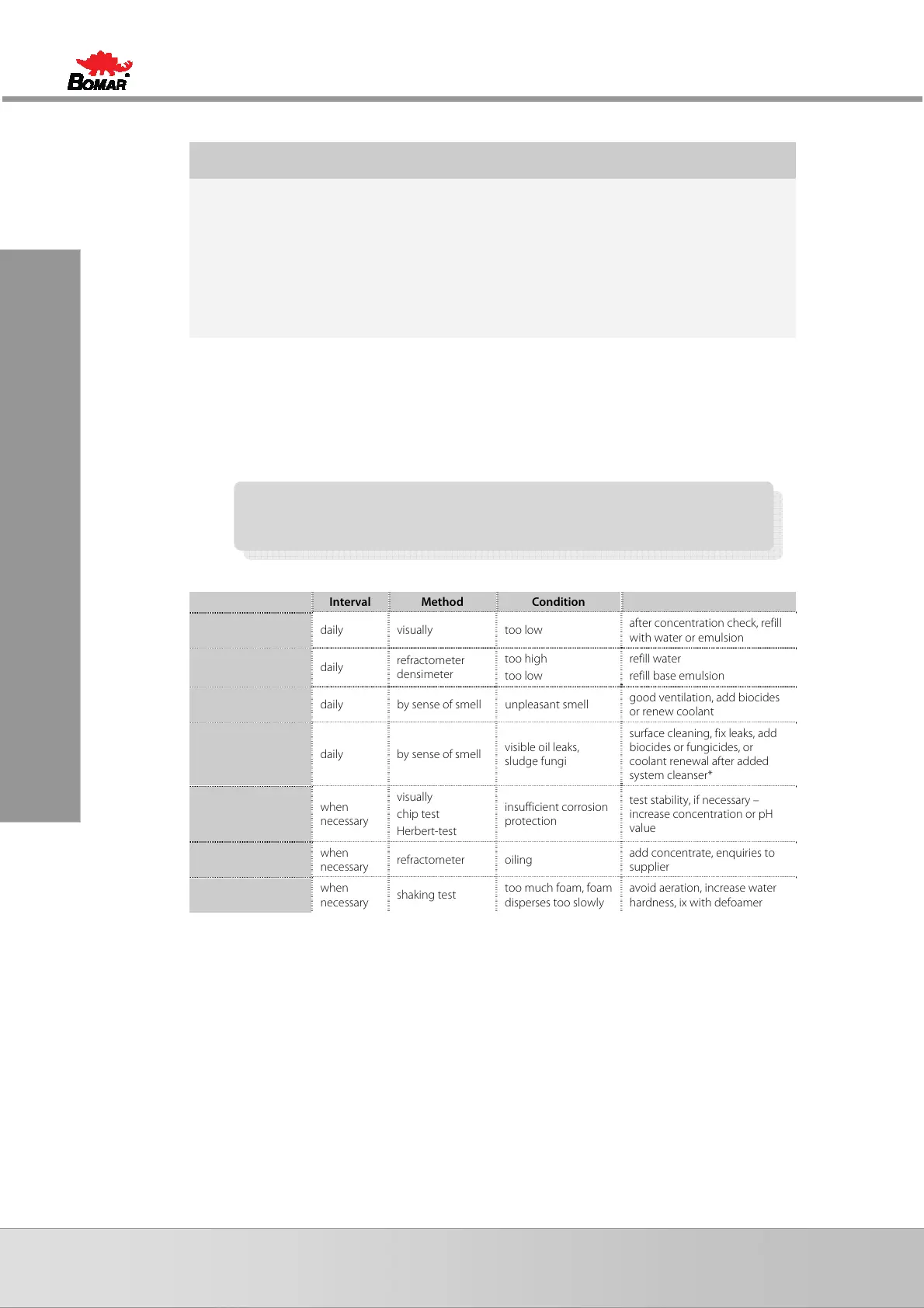

4.4.1. Coolant device inspection

The state of the cooling agent has significant influence on the cutting quality and on

the operational life of the machine. Lifetime of the cooling liquid is 1 year, after this time

we recommend change the cooling liquid. This time is dependent on the degree of

pollution cooling liquid (especially with oils) and on the other factors.

Check level of the cooling liquid and function of the pump periodically!

Check the state of the cooling agent according to the following table:

Testing Interval Method Condition Precaution

Liquid level daily visually too low

after concentration check, refill

with water or emulsion

Concentration daily

refractometer

densimeter

too high

too low

refill water

refill base emulsion

Smell daily by sense of smell unpleasant smell

good ventilation, add biocides

or renew coolant

Contamination

daily by sense of smell

visible oil leaks,

sludge fungi

surface cleaning, fix leaks, add

biocides or fungicides, or

coolant renewal after added

system cleanser*

Corrosion-

protection

when

necessary

visually

chip test

Herbert-test

insufficient corrosion

protection

test stability, if necessary –

increase concentration or pH

value

Stability

when

necessary

refractometer oiling

add concentrate, enquiries to

supplier

Foam reaction

when

necessary

shaking test

too much foam, foam

disperses too slowly

avoid aeration, increase water

hardness, ix with defoamer

* According to manufacturers’ instructions

4.4.2. Chips disposal

Chips resulting from cutting operations must be disposed of in accordance with the

relevant regulations.

• Let the chips drip excess fluid!.

• Fill a watertight container with the chips! Be careful that the container does not

leak, because even after a long dripping time, they still contain coolant residue.

• Place the container into the care of a disposal company equipped for the disposal of

chips contaminated with cooling liquid. In case the machine is equipped with micro-

spray installation, the chips must also be handed over to a disposal company.

Note:

If the state of the cooling liquid is not satisfactory, the cooling

liquid must be changed.

Loading...

Loading...