67

Závady

Troubleshooting

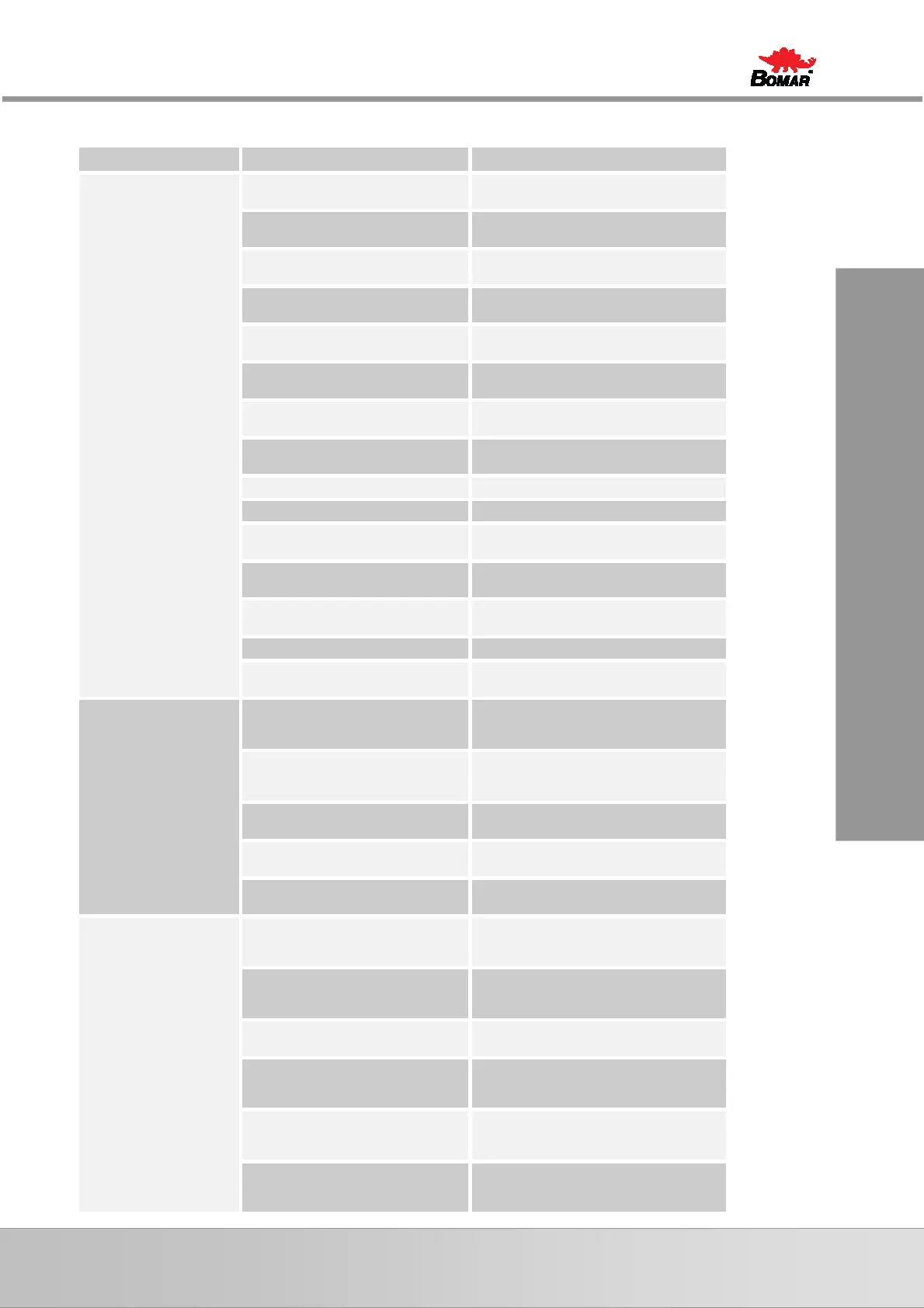

5.1. Mechanical problems

Problem Possible causes Repair

1. Slanting cut

- Wrongly adjusted hard metal guides. Set according to the chapter „Servicing and

adjustment“

- Worn hard metal guides. Replace to the chapter „Worn pieces

replacement“

- Wrongly adjusted cubes of the saw

band guiding.

Set according to the chapter „Servicing and

adjustment“

- Worn bearings of the saw band guiding. Replace according to the chapter „Worn pieces

replacement“

- Wrongly adjusted swarf brush. Set according to the chapter „Servicing and

adjustment“

- Worn swarf brush. Replace according to the chapter „Worn pieces

replacement“

- Insufficient saw band stretching. Rise the saw band stretching and set the limit

switch.

- Wrongly chosen tooth system of the

saw band.

Replace the saw band and keep the instructions

of manufacturer on new saw band choice.

- Worn saw band. Replace the saw band.

- Wrongly balanced roller conveyor. Set the roller conveyor.

- Dirty feeding board. Cleanse the feeding board from debris, chip and

residue material.

- Guiding arm and guiding cube are

loosened.

Clamp the guiding arm.

- Guiding arm and cube are too far from

the material.

Set the guiding cube to the material.

- Too fast cutting rate. Lower the material feeding speed.

- Unexpected oscillation in material

quality.

Set the cut and feeding speed to the relevant

material.

2. The cut is not cut

upon desired angle

- Securing lever is loosened. Check the securing lever efficiency and carry out

its adjustment according to chapter „Servicing

and adjustment“.

- Set angle does not match the cut angle. Check the angle adjustment with a protractor

and possibly set it according to chapter „Servicing

and adjustment“.

- Insufficient saw band stretching. Stretch the saw band and set the limit switch

according to chapter „Servicing and adjustment“.

- Guiding arm and guiding cube are

loosened.

Fasten the guiding arm and the cube.

- Dirt between material and clamping

jaw.

Cleanse the material and mating jaw.

3. Short lifetime of the

saw band

- Insufficient saw band stretching. Raise the tightening of the saw band set the

scanner of saw band tightening according to

chapter „Servicing and adjustment“.

- Worn swarf brush. Check the swarf brush condition and replace it in

case of excessive use as described in chapter

„Worn pieces replacement“

- Wrongly adjusted swarf brush. Check swarf brush adjustment, set it according to

chapter „Servicing and adjustment“

- Over stretched saw band Lower stretching of the saw band and set the

limit switch of the saw band stretching according

to chapter „Servicing and adjustment“

- Wrongly adjusted hard metal guides. Check the adjustment of the hard metal guides

and carry out adjustment as described in chapter

„Servicing and adjustment“

- Worn hard metal guides of the saw

band.

Check the condition of the hard metal guide and

if it is too worn, replace hard metal guides

according to chapter „Worn pieces replacement“

Loading...

Loading...