69

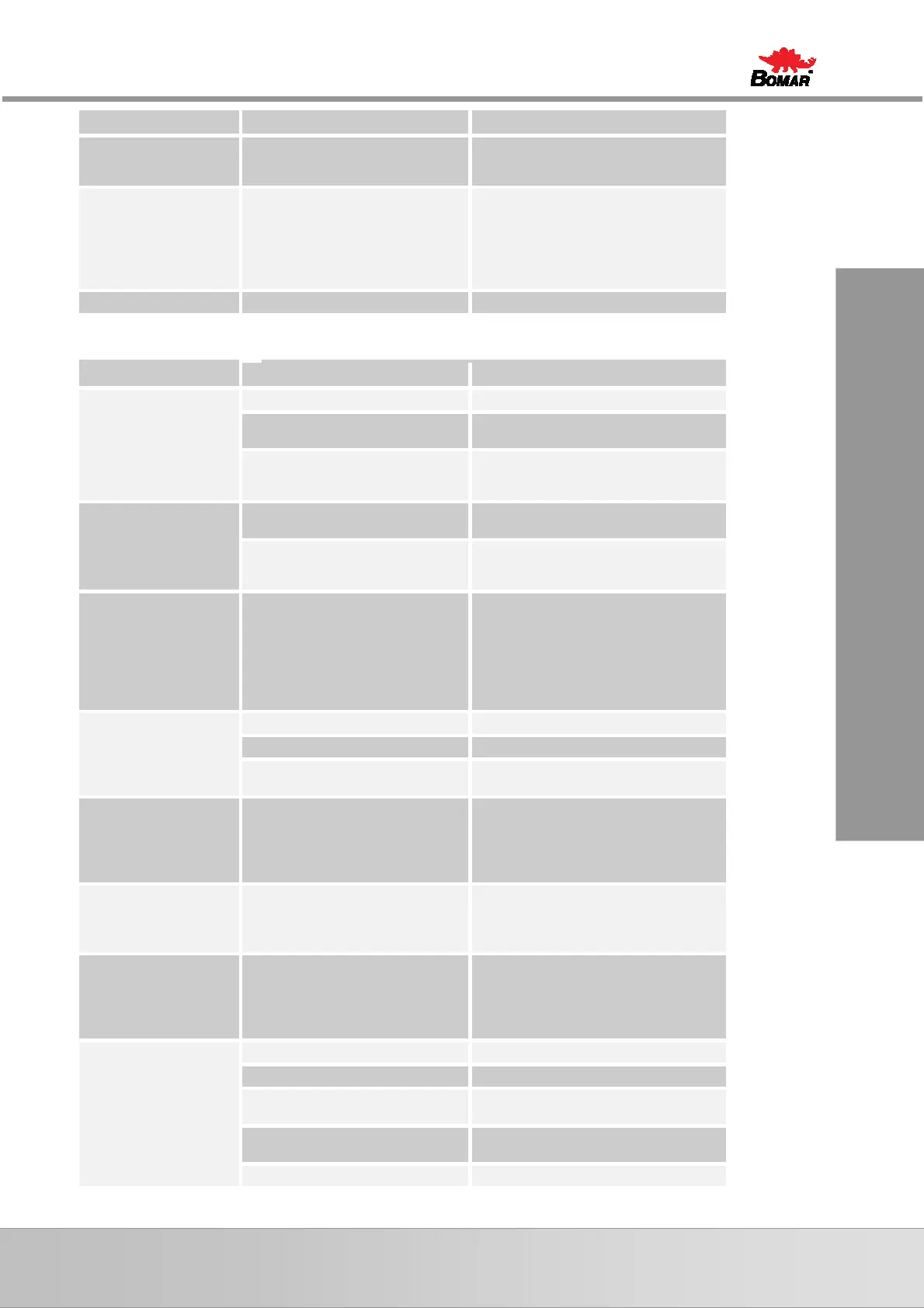

Závady

Troubleshooting

Problem Possible causes Repair

- The brush position and the brush cover

is adjusted wrong – with the brush

cannot be turned.

The brush cover must be posed, in order to the

brush can be turned.

12. The saw arm

periodically rise and

fall during the cut; this

cause short lifetime of

the saw band.

- Backslash in driving wheel lodgement

on the shaft.

Change the driving shaft for a long one, new

bearings, distance ring, new driving wheel, spring,

two covers on the forehead of the shaft + screws.

- Worn channel for spring.

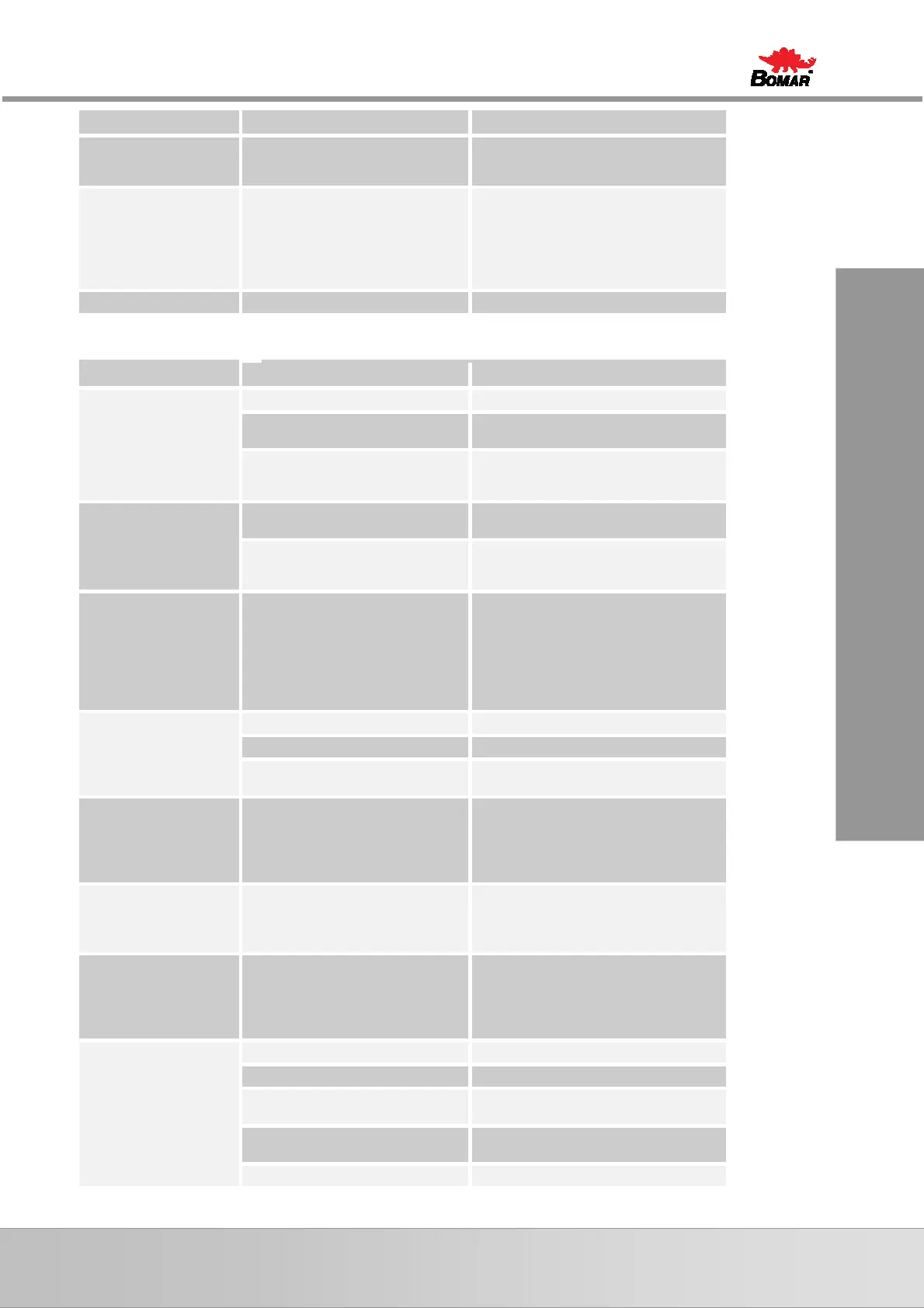

5.2. Electric and hydraulic problems

Problem Possible causes Repair

1. Machine is not

possible start.

-

In socket is not voltage Line voltage must be checked.

-

Transfer relay is closed (thermal

protector)

Each FA relay must be checked.

-

Limit switch of saw band stretching,

cover of frame or cover of saw band is

not started.

Check of saw band stretching and covers closing.

2. When cut is finished,

the frame is not

raising.

- Bottom limit switch is adjusted wrong. Bottom limit switch must be adjusted according

to chapter ADJUSTING.

- In hydraulic (pneumatic) ring is error.

HYTOS (BOSCH) is not acting to frame

uplift.

Function of magnetic valve must be checked,

valve must be closed, voltage of clamps and

inductor must be checked.

3. Electric motor and

pump are without

voltage. Between

contactor and

thermal protector is

not voltage.

- Wrong contactor. Replace contactor of engine.

4. The indicator of speed

saw band is not

functional.

- Sensor of speed is not adjusted. Sensor of speed must be adjusted.

- Defective display The display must be changed.

- Wrong sensor – diode of indicator

speed is not light.

Sensor must be changed and adjusted.

5. Protector is switched

off from engine

hydraulic aggregate

MA3 sometimes.

- Into hydraulic system is high working

pressure.

Service engineer must reduce the pressure in

hydraulic system.

6. The hydraulic

aggregate cannot be

started

Auxiliary contact on thermo-relay FA1 is

defective.

Replace the defective contact on motor starter

FA1.

7. Hydraulic aggregate is

switched on but the

saw arm or the main

vice is not functional

- Wrong connection of electrical supply.

The electrical phases are connected

conversely.

The phases must be switched. Only service

engineer can do this.

8. Cooling is not active

Lack of cooling agent. Fill the tank with cooling agent.

- Thermal relay is defective Change the thermal relay

- Input hosepipe is broken or obstructed. Check the cooling circuit and perhaps cleanse

cooling system.

- Cooling pump protection is defective Check the protection of cooling pump if need

change it.

- Cooling pump is defective. Replace the cooling pump.

Loading...

Loading...