BRP-Rotax

MAINTENANCE MANUAL LINE

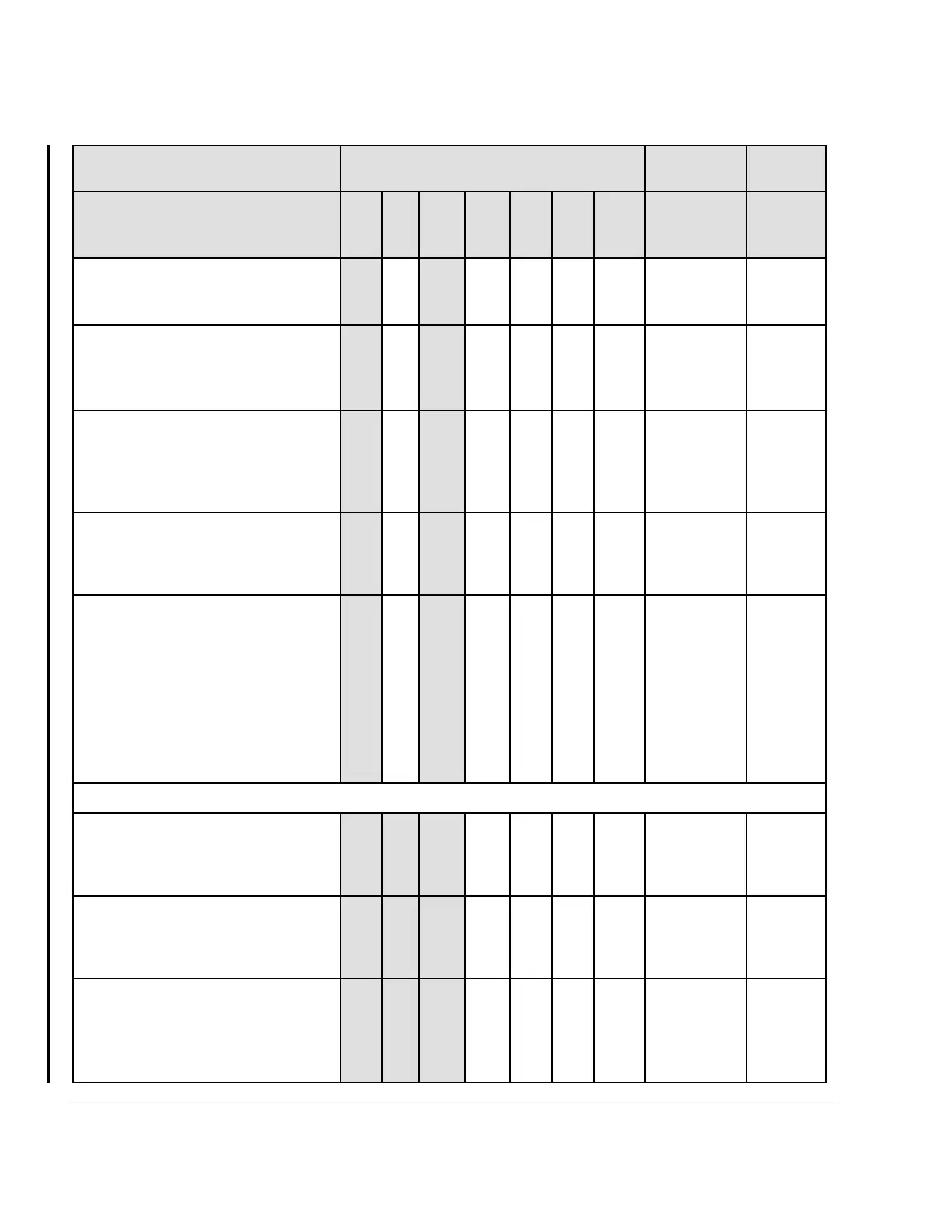

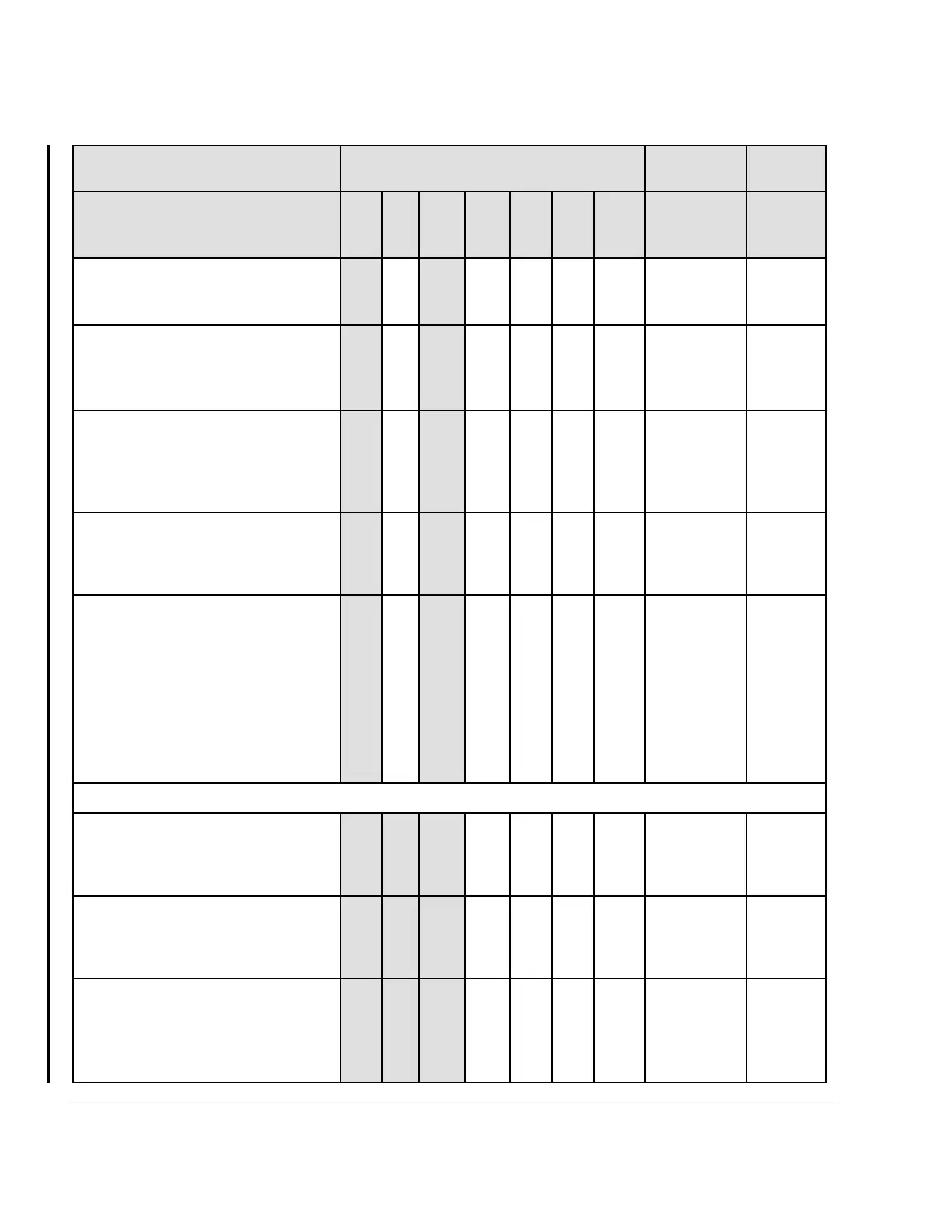

Points of Inspection

Interval Operating hours Chapter

Reference

Signa-

ture

* no periodic maintenance (re-

quirement after the first 25 hours

of operation)

25* 50 100 200 400 600 1000

Inspect the wiring and its connec-

tions for secure fit, damage and

signs of wear.

X X 12–20–00

Check of

wiring

Inspect engine suspension and fas-

teners (GENUINE ROTAX® ) for se-

cure fit, including damage from heat,

deformation, cracks.

X X 12–20–00

Checking

the engine

suspension

Check the airbox (GENUINE RO-

TAX® ) incl. air flap actuation. In-

spect sensors for tight fit, damage

from heat, damage and signs of

wear.

X X

Checking the air filter.

X X 12–20–00

Cleaning

the dry air

filter

Inspect of the GENUINE ROTAX®

exhaust system included in the

standard delivery.

NOTE

If there is no standard/genuine

exhaust system in use, the speci-

fications of the manufacturer

must be observed.

X X

7) Oil change

Drain oil from oil tank.

X X

(5

X 12–20–00

Oil change,

Flushing the

oil circuit

Check the oil tank and clean the oil

tank if contaminated.

X X

(5

X 12–20–00

Oil change,

Cleaning

the oil tank

Refill oil tank with approx. 3 litres of

oil. For oil quality, see Operators

Manual latest edition.

X X

(5

X 12–20–00

Flushing the

oil circuit,

Purging the

oil system

05–20–00

Page 12

January 01 2020

Effectivity: 912 Series

Rev. 0

Loading...

Loading...