Software update

CryoProbe User Manual BRUKER 67 (107)

Software update 6.3

0

See "Load firmware" on page 37

and "Load additional Xwin-nmr software"

on page 52 in the CryoProbe System Installation Manual.

Cleaning 6.4

0

Cleaning the sample cavity 6.4.1

The CryoProbe sample cavity is extremely fragile. Even a tiny scratch inside can

spoil the CryoProbe performance and entail a major repair action. Preventive

cleaning is not recommended - clean only in case of problems.

If dirt or liquid must be removed from the sample cavity, follow the procedure giv-

en in Table 6.4.

below.

b.6 Put the protective cap onto the He steel-cylinder.

b.7 Replace the He steel-cylinder.

CAUTION: When moving the steel-cylinders, keep them as far as possi-

ble from the magnet but always outside the 0.5 mT range.

b.8 Attach the new He steel-cylinder securely to a wall, mount the He Reg-

ulator, and fix the safety cable of the He Hose at the He steel-cylinder.

b.9 Open the valve on the He steel-cylinder. The primary pressure should

read about 200 bar and the secondary pressure 22-25 bar as before.

b.10 He leakage test

:

Close the He steel-cylinder main valve again and wait for about ½ h

until the pressure has equilibrated across the line. Read the secondary

pressure, wait for about 2 h, and read again. If the pressure has

dropped, search for leaks with a He detector or an appropriate liquid

(see "He leakage" on page 81

).

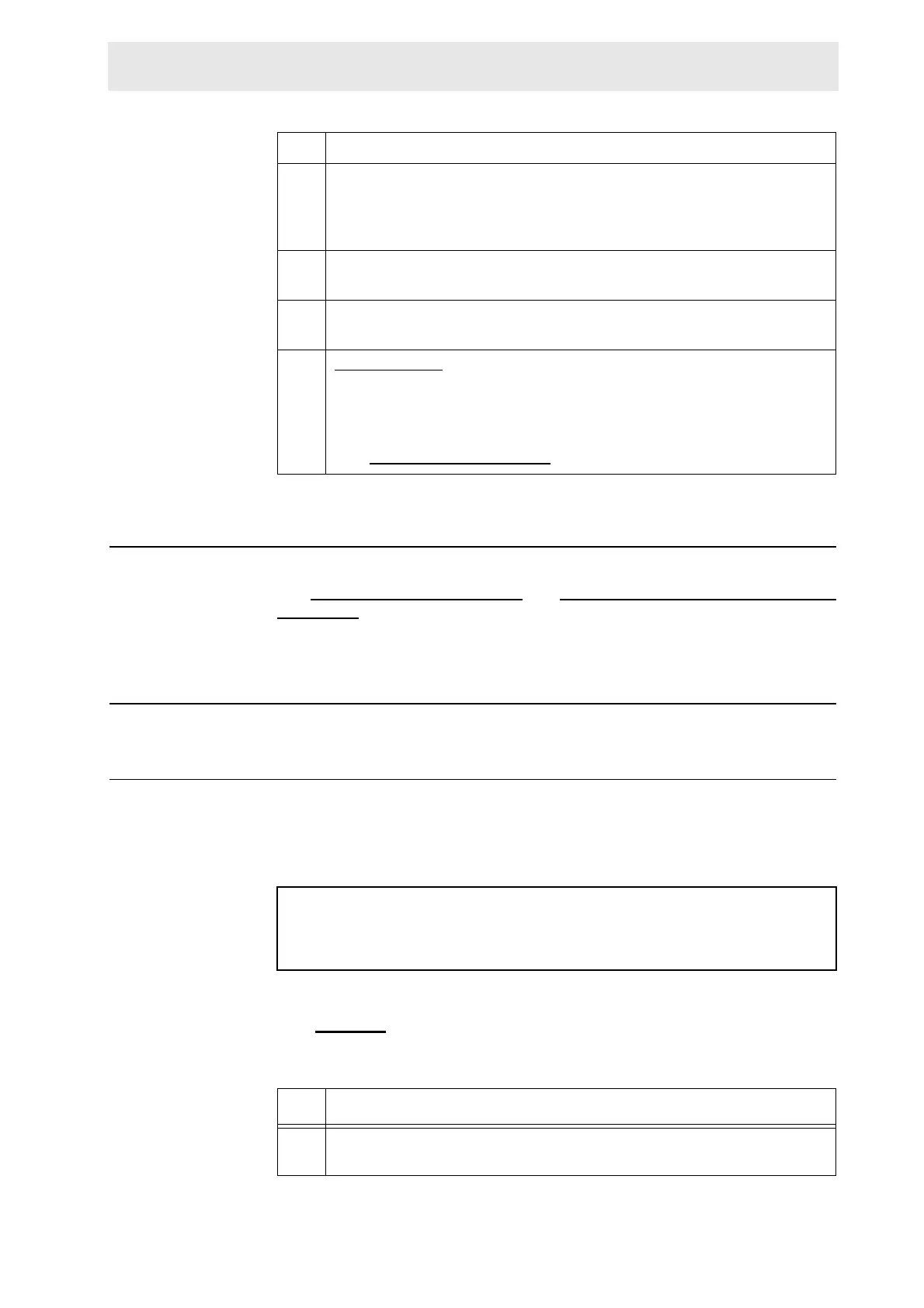

Table 6.4. Clean the CryoProbe sample cavity

step action

k.1 Remove the CryoProbe from the magnet and observe all handling pre-

cautions.

CAUTION: Do not put any objects or cleaning devices into the sample

cavity! In particular, soft cotton buds must not be introduced

under any circumstances - the CryoProbe cavity would al-

most inevitably be damaged!

Loading...

Loading...