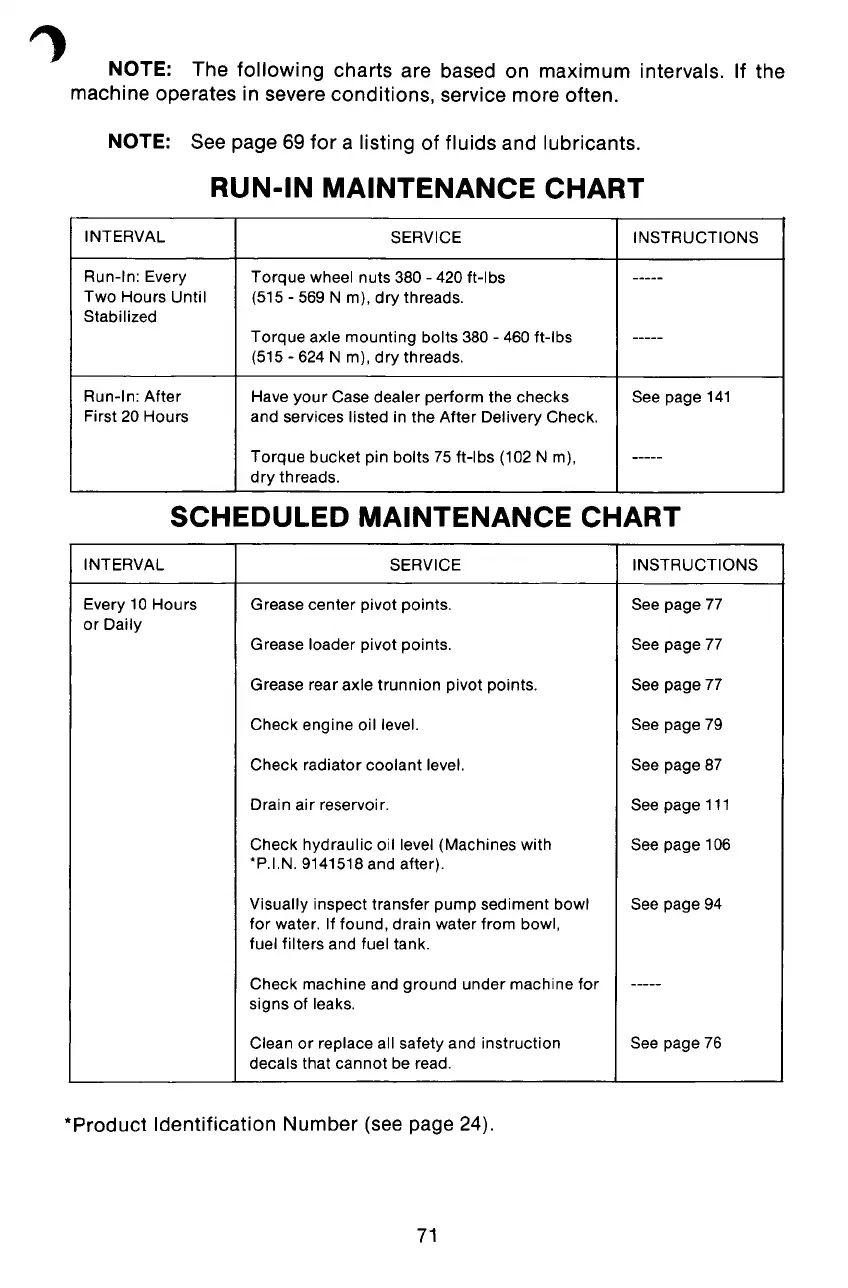

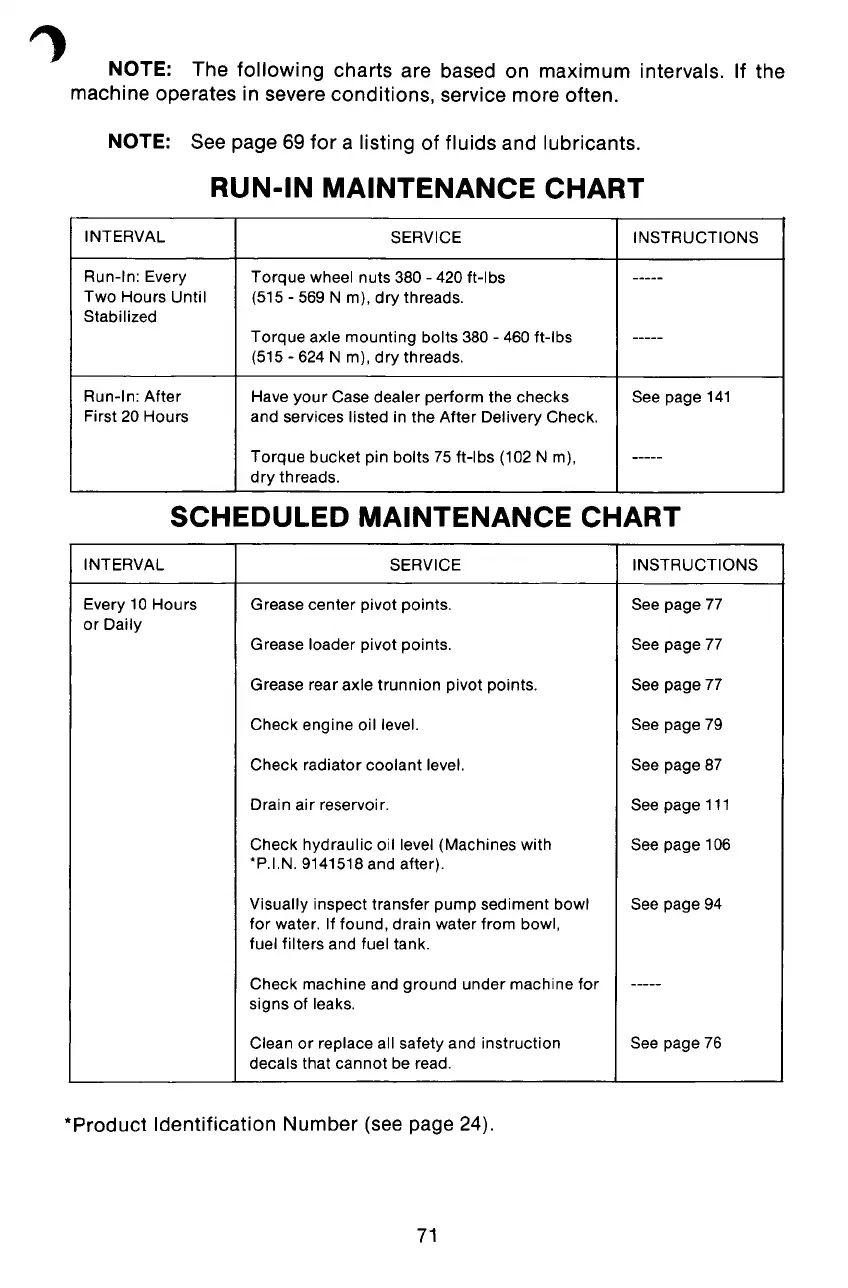

NOTE: The following charts are based on maximum intervals. If the

machine operates in severe conditions, service more often.

NOTE: See page 69 for a listing of fluids and lubricants.

RUN-IN MAINTENANCE CHART

INTERVAL

SERVICE INSTRUCTIONS

Run-In: Every

Torque wheel nuts 380 - 420 tt-lbs

-----

Two Hours Until

(515 - 569 N rn), dry threads.

Stabilized

Torque axle mounting bolts 380 - 460 ft-Ibs

-----

(515 - 624 N rn), dry threads.

Run-In: After

Have your Case dealer perform the checks See page 141

First 20 Hours

and services listed in the After Delivery Check.

Torque bucket pin bolts 75 ft-Ibs (102 N m),

-----

dry threads.

SCHEDULED MAINTENANCE CHART

INTERVAL

SERVICE INSTRUCTIONS

Every 10 Hours

Grease center pivot points.

See page 77

or Daily

Grease loader pivot points.

See page 77

Grease rear axle trunnion pivot points. See page 77

Check engine oil level. See page 79

Check radiator coolant level.

See page 87

Drain air reservoir. See page 111

Check hydraulic oil level (Machines with See page 106

*P.I.N. 9141518 and after).

Visually inspect transfer pump sediment bowl See page 94

for water. If found, drain water from bowl,

fuel filters and fuel tank.

Check machine and ground under machine for

-----

signs of leaks.

Clean or replace all safety and instruction See page 76

decals that cannot be read.

*Product Identification Number (see page 24).

71

Loading...

Loading...