TROUBLESHOOTING WELDSKILL 250, 350

Manual 0-5186 6-1

Troubleshooting

SECTION 6:

TROUBLESHOOTING

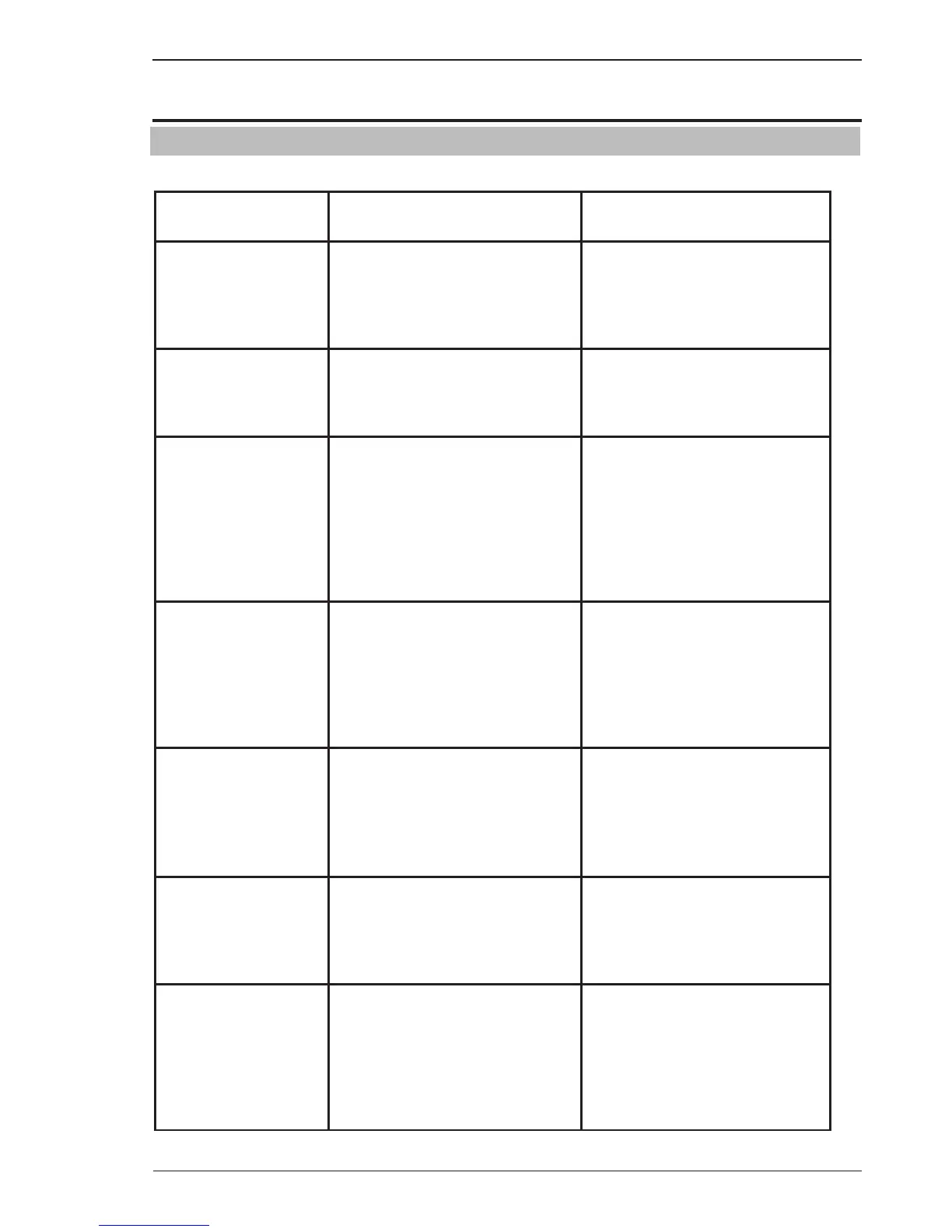

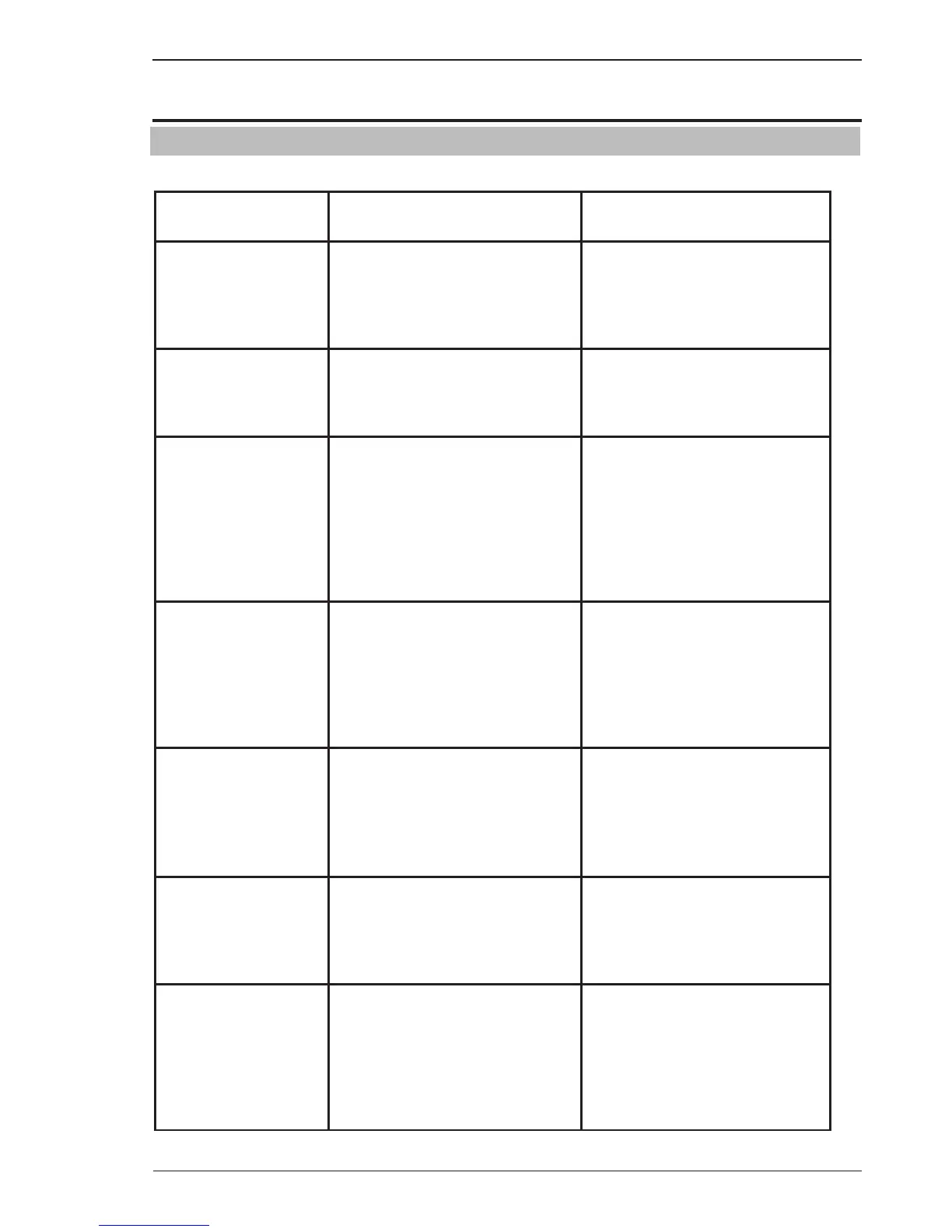

6.01 Power Source / Wirefeeder Faults

The following table is a guide for analysing problems and making repairs to the Power Source/Wirefeeder.

FAULT CAUSE REMEDY

1 Mains supply voltage

is ON. Indicator light

is not lit and welding

arc can not be

established.

A

B

Primary fuse is blown.

Broken connection in primary

circuit.

A

B

Replace primary fuse.

Have an Accredited CIGWELD

Service Provider check primary

circuit.

2 Mains indicator

light is not lit but

welding arc can be

established.

Burnt out Indicator light. Have an Accredited CIGWELD

Service Provider replace Indicator

light.

3 Mains supply

voltage is ON and

power Indicator

is lit however unit

will not commence

welding when the

torch trigger switch is

depressed.

A

B

Faulty torch trigger

Circuit breaker tripped

A

B

Repair or replace torch trigger

switch/leads

Reset Circuit Breaker(s)

4 Mains supply voltage

is ON, no wire feed

but gas flows from

the MIG Torch when

the torch trigger

switch is depressed.

A

B

Electrode wire stuck in conduit

liner or contact tip (burn-back

jam).

Faulty control PCB

A

B

Check for clogged / kinked MIG

Torch conduit liner or worn

contract tip. Replace faulty

components.

Have an Accredited CIGWELD

Service Provider investigate the

fault.

5 Wire feeds when

the torch trigger

switch is depressed

but arc cannot be

established.

A

B

Mig torch polarity lead is not

connected into a welding output

terminal.

Poor or no work lead contact.

A

B

Connect the MIG torch polarity

lead to either the positive welding

output terminal or negative output

terminal as required.

Clean work clamp area and ensure

good electrical contact.

6 Inconsistent wire feed A

B

C

D

Worn or dirty contact tip

Worn feed roll.

Excessive back tension from wire

reel hub.

Worn, kinked or dirty conduit liner

A

B

C

D

Replace if necessary.

Replace if necessary.

Reduce brake tension on spool

hub

Clean or replace conduit liner

7 No gas flow A

B

C

D

Gas hose is cut.

Gas passage contains impurities.

Gas regulator turned off.

Empty Cylinder

A

B

C

D

Replace or repair.

Disconnect gas hose from the rear

of Power Source or wirefeeder

then raise gas pressure and blow

out impurities.

Turn on.

Replace cylinder.

Loading...

Loading...