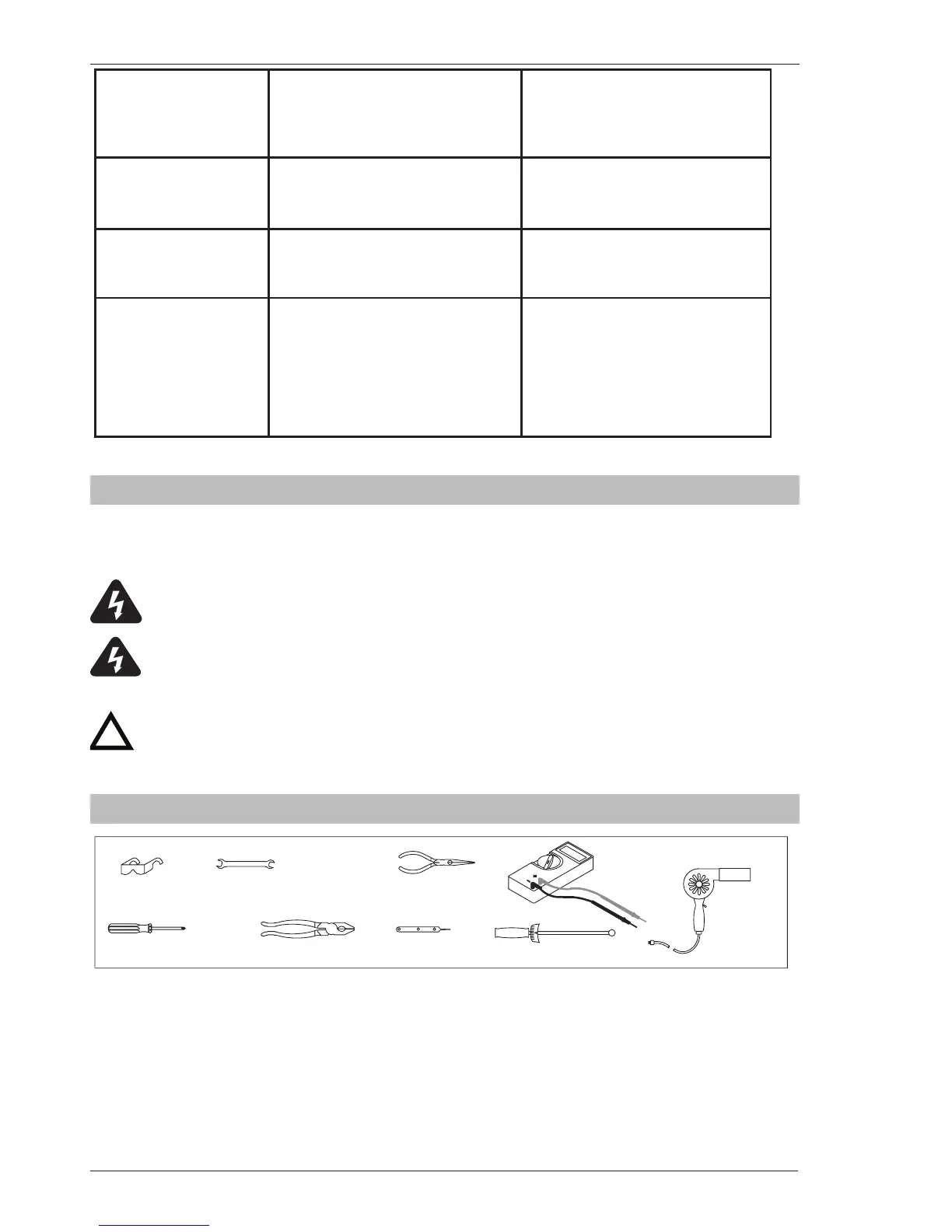

Troubleshooting

6-2 Manual 0-5186

WELDSKILL 250, 350 TROUBLESHOOTING

8 Gas flow continues

after the torch trigger

switch has been

released.

Gas valve has jammed open due

to impurities in the gas or the gas

line.

Have an Accredited CIGWELD

Service Provider repair or replace

gas valve.

9 Wire does not feed

when torch trigger

depressed

A

B

Faulty trigger switch / lead

Circuit breaker tripped

A

B

Repair or replace Torch / trigger

lead

Reset Circuit Breaker(s)

10 Wire continues to

feed when torch

trigger released

A

B

Power Source in 4T (LATCH) mode

Torch trigger leads shorted

A

B

Change to 2T (NORMAL) mode

Repair or replace Torch / trigger

lead

11 Wire feeds when the

torch trigger switch is

depressed but arc can

not be established

and OVERHEAT led is

illuminated

Power Source Overtemperature

Protection circuit has operated

Cease welding and allow Power

Source to Cool for 10 minutes.

Overheat led will extinguish when

the Power Source has cooled

sufficiently.

Table 6-1 Power Source/Wirefeed Faults

6.02 Checking Unit Before Applying Power

Turn SW1 to OFF position, and disconnect unit from primary line voltage before working on unit.

Significant DC voltage can remain on capacitors after unit is Off. Wait until all front panel LED’s are off

before removing case.

Before troubleshooting or applying power to unit, complete the following checks to avoid causing further

damage.

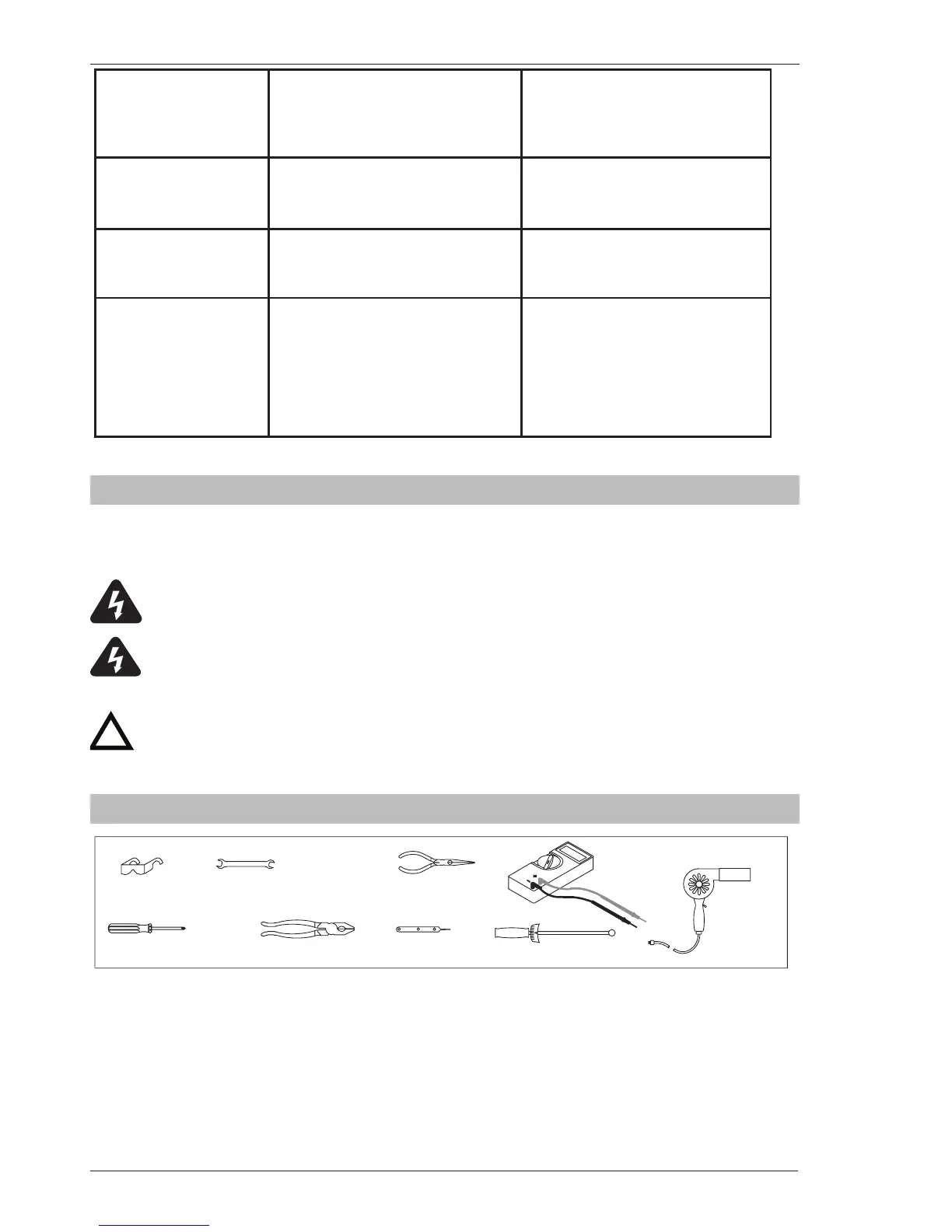

6.03 Tools Needed for Troubleshooting and Servicing

Art # A-09849

Loading...

Loading...