20

GeneralInformationENGINE–SUBARUEX40

524

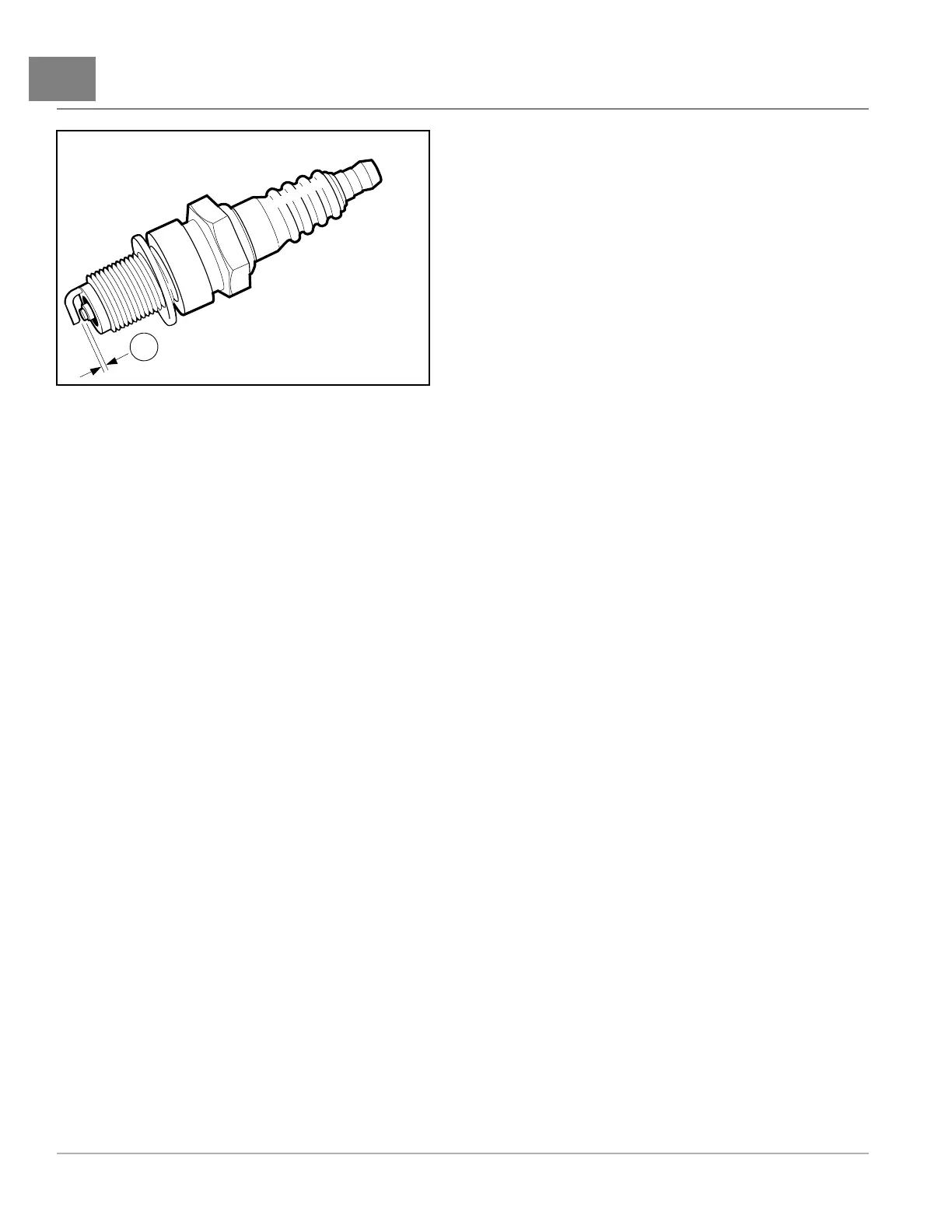

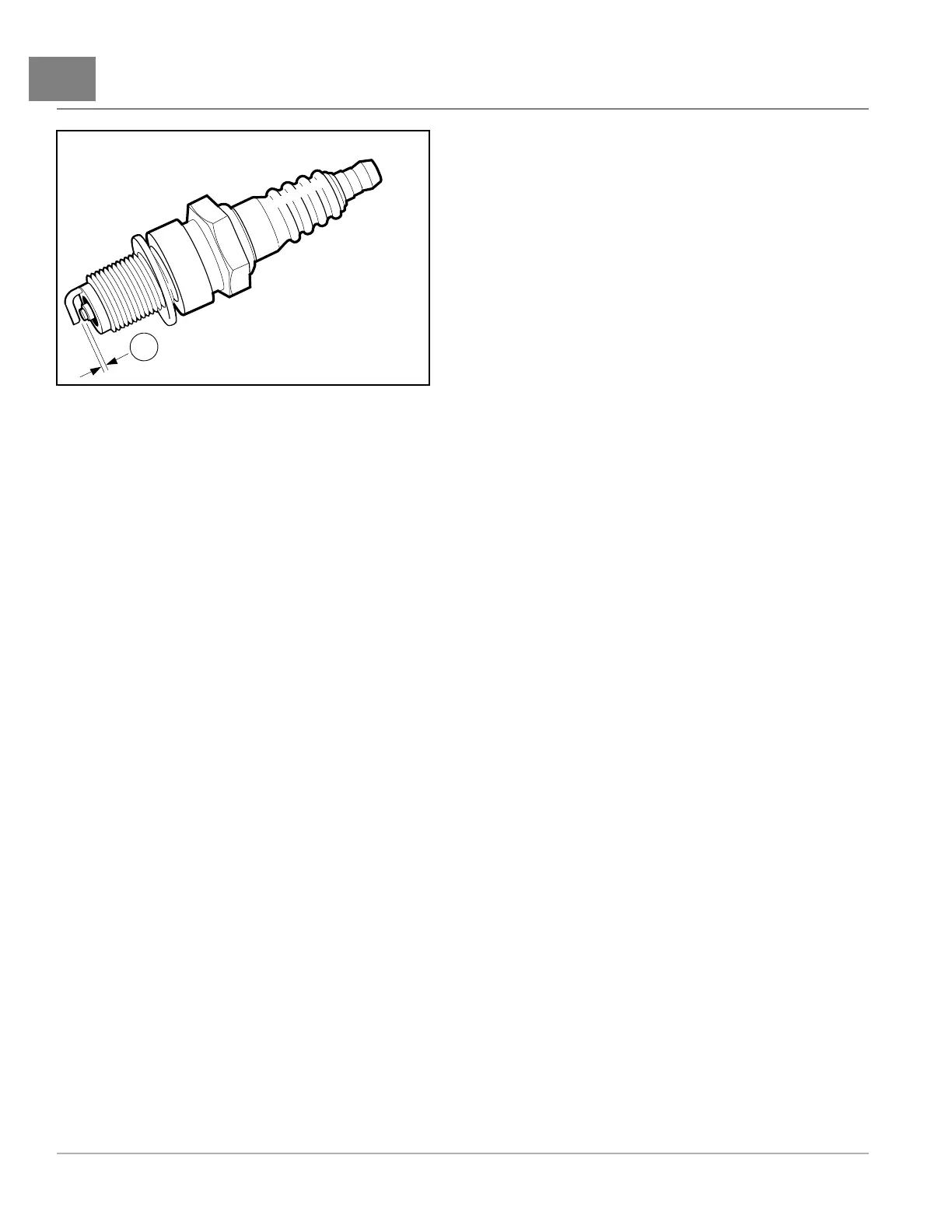

Figure20-4SparkPlug

TestingtheSparkPlug

Checkthesparkingabilityofacleanedandproperlygappedplugonasparkingcomparatorifpossible.Sparkshould

beblueandstrongandabletojumpa5/16-in.(8mm)gap.

SettingtheSparkGap

1.Passacontactpointlebetweentheelectrodestoproduceat,parallelsurfacestofacilitateaccurategauging.

2.Useawiretypegauge.Bendtheoutsideorgroundelectrodesoonlyaslightdragonthegaugeisfeltwhen

passingitbetweentheelectrode.Nevermakeanadjustmentbybendingthecenterelectrode.Setgap(A)from

0.024to0.028in.(0.6to0.7mm)(Figure20-4,Page20-6).

SparkPlugInstallation

NOTE:Beforeinstallingtheplug,checktheconditionofthethreadsinthecylinderhead.Softendepositsincylinder

headthreadswithpenetratingoilandcleanthethreadswithatapifnecessary.

Useahightemperature,anti-seizelubricantonthethreadsofthesparkplugtoreducefrictionwheninstalling

anewplug,andreduce“gauling”andthreadseizingforfuturereplacements.

Installthesparkplugbythreadingitinuntilngertight,thentightenthesparkplugtothefollowingtorque:

•New:120lb·in(13.5N·m).

•Re-tightening:216lb·in(24.5N·m).

BREATHER

Thefunctionofthebreatheristocreateavacuuminthecrankcasewhichpreventsoilfrombeingforcedoutofthe

enginethroughthepistonrings,oilsealsorgaskets.Thebreatherhasareedvalvewhichlimitsthedirectionofairow

causedbythepistonmovingupanddown.Aircanowoutofthecrankcase,buttheone-wayreedvalveblocksreturn

owandthereforemaintainsavacuuminthecrankcase.

Oilladenairinthecrankcasepassesthroughthereedvalveandexpandsintotherockercamber.Intherocker

cambermostoilseparatesfromtheairanddrainsbacktothecrankcase.Theairpassesthroughatubeandventsto

theintakemanifold.

Page20-62018OnwardMaintenanceandServiceManual

Loading...

Loading...