•

Clamp the feed pump with a vise and disassemble the plugs (30, 32), strainer (31) and gaskets

(35, 36).

•

Take off the priming pump (25), plug (16), both gaskets (18), spring (15), and check valve (14).

•

Take off the prig (7), gasket (8), spring (6), and piston (5) on the piston side.

•

Pull out the snap ring (20) holding the tappet (10).

•

Disassemble the snap ring, then take off the tappet (10) and push rod (1).

3) Inspection

•

If the check valve is damaged or scored on its seat face, replace it with a new one.

•

Inspect the piston and tappet for damage.

•

Replace the push rod if excessively worn, and replace together with the pump housing if

required. The inspection for wear should be performed in the same procedure as for suction

pressure test described below.

4) Reassembly

Reassembly operation is performed in reverse order of disassembly. All the gaskets must be

replaced with new ones at reassembly.

NOTE :

Check the item no. 30 before assembling it whether it is the fuel strainer bolt.

Clean it when fuel filter cartridge is replaced.

5) Testing

(1) Suction capacity test

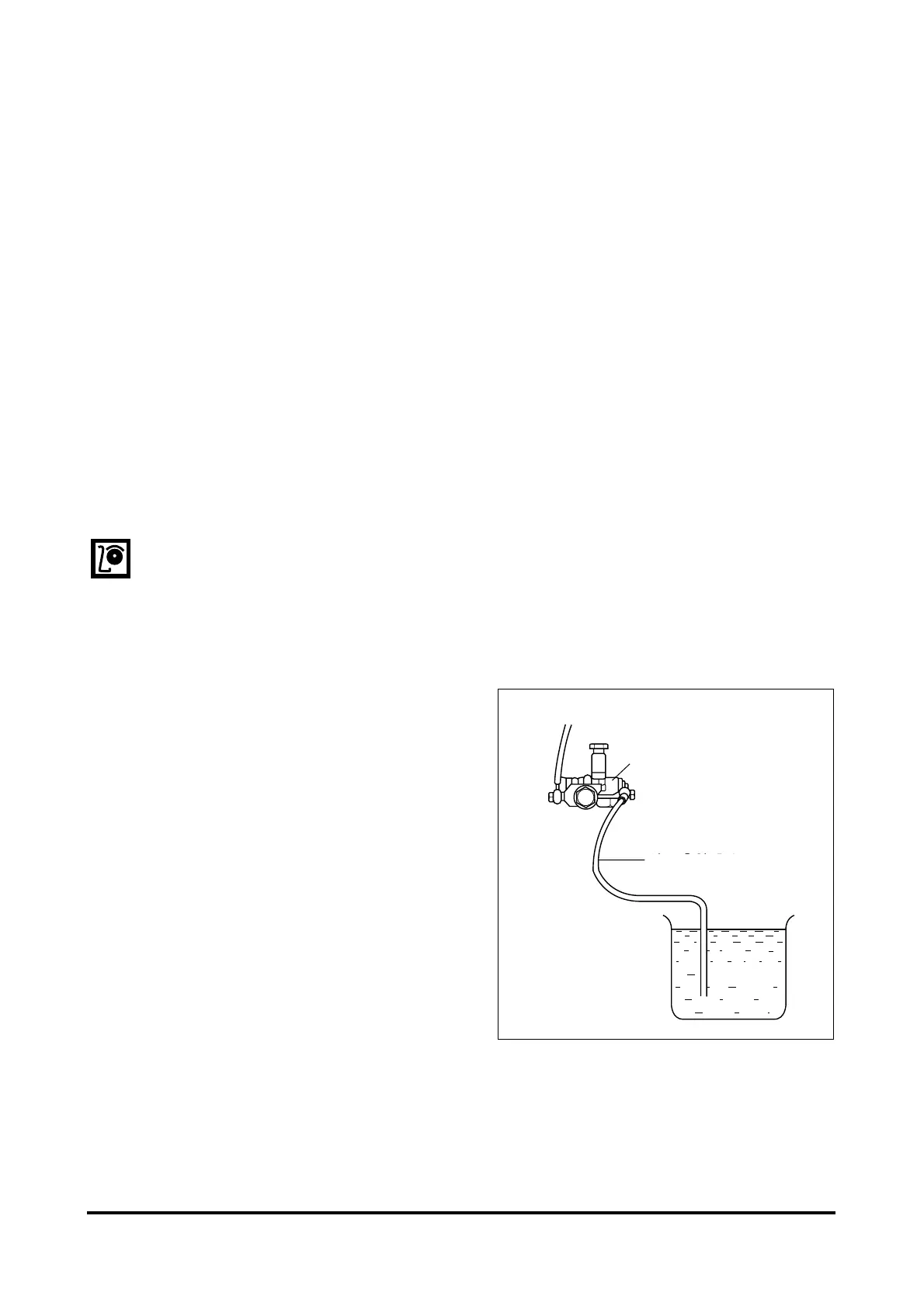

Connect one end of a hose to the inlet

side of the feed pump and immerse the

other end of it into the fuel tank as illus-

trated.

Hold the feed pump in position about 1 m

above the level of fuel in the fuel tank.

Operate the tappet at the rate of 100 rpm

and check to see if fuel is drawn in and

delivered for 40 seconds or so.

- 137 -

MAINTENANCE OF MAJOR COMPONENTS

Loading...

Loading...