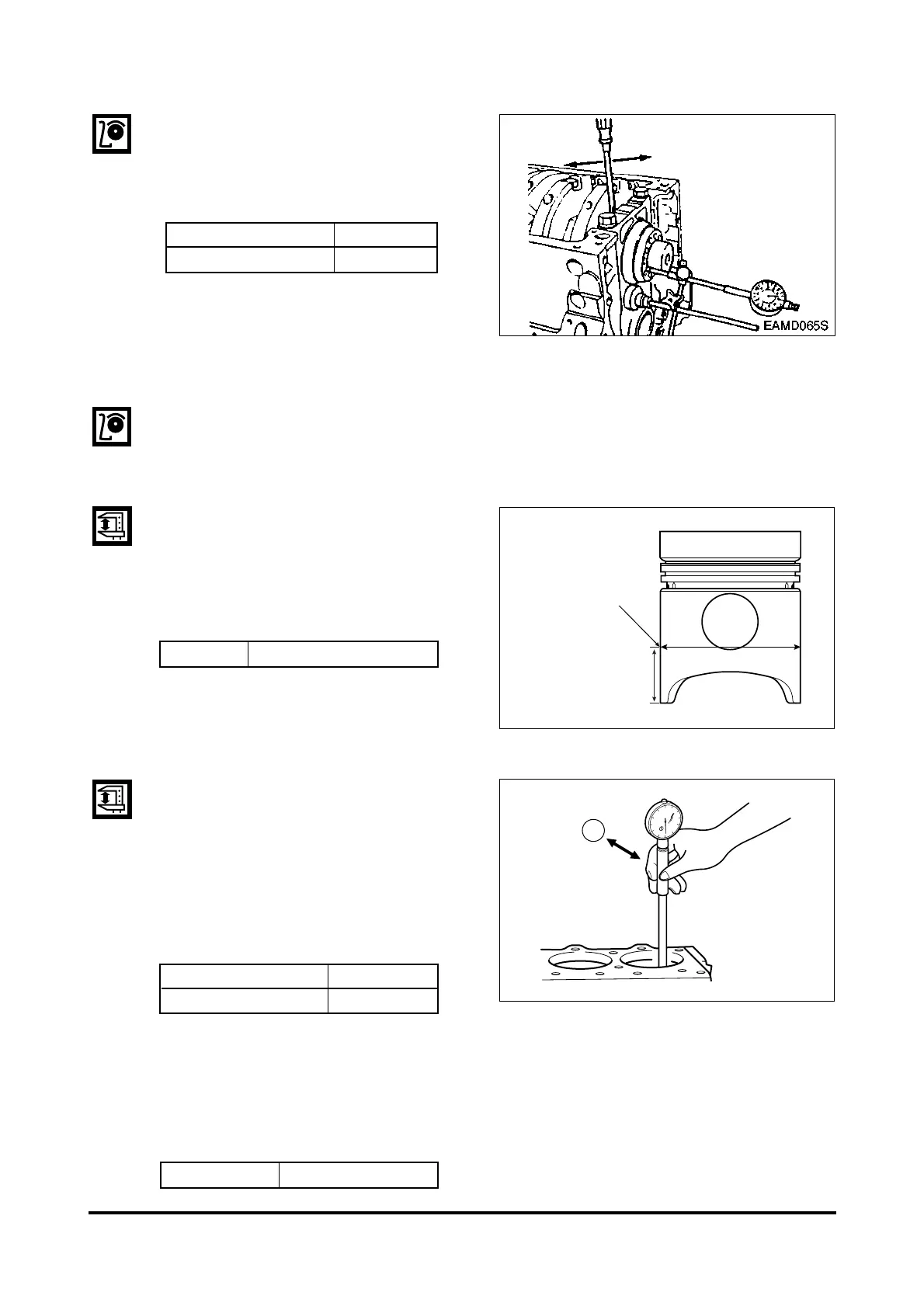

4) Crank shaft end play

•

Assemble the crankshaft to the cylin-

der block.

•

With a dial gauge, measure crank-

shaft end play.

3.2.

8. Piston

1) Visual check

•

Visually check the pistons for cracks, scuff or wear, paying particular attention to the ring

groove.

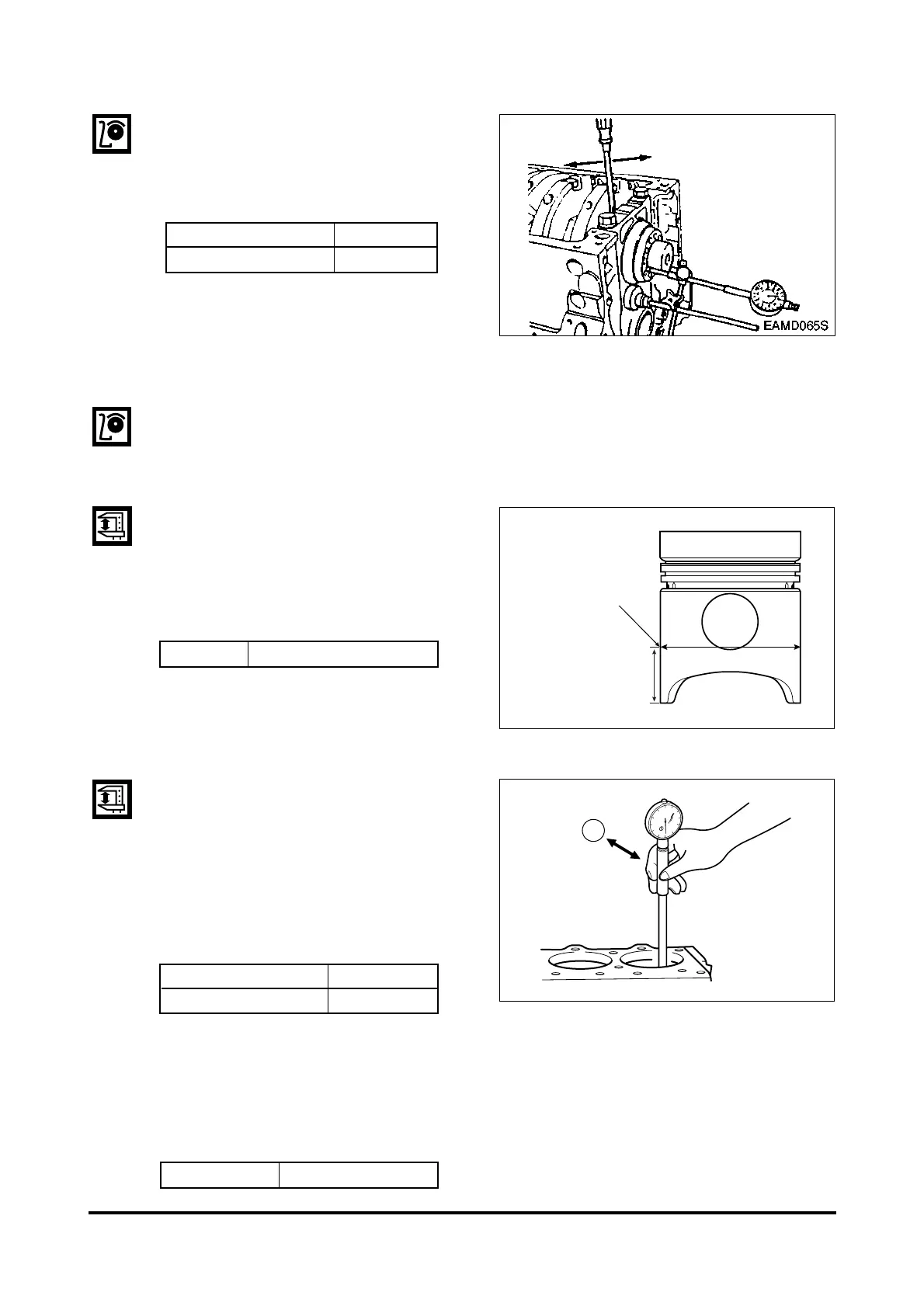

2) Clearance between the piston and cylinder liner

•

With an outside micrometer, measure

the piston outside diameter at a point

18mm away from the lower end of pis-

ton skirt in a direction at a right angle

to the piston pin hole.

•

Using a cylinder bore gauge, measure

cylinder liner inside diameter at 3

points (cylinder top ring contacting

face, middle, and oil ring contacting

face on BDC) in a direction at an angle

of 45˚ Take the mean value with the

largest and smallest values excepted.

•

The clearance is computed by subtracting the piston outside diameter from the cylinder liner

inside diameter. Replace either piston or cylinder liner, whichever damaged more, if the

clearance is beyond the specified limit.

Clearance between piston and liner

- 72 -

INSPECTION AND MEASUREMENT

Standard Limit

0.15 ~ 0.325

mm

0.5

mm

Loading...

Loading...