6.6. V-belts

(1) Change the V-belts if necessary

If in the case of a multiple belt drive, wear or differing tensions are found, always replace

the complete set of belts.

(2) Checking condition

Check V-belts for cracks, oil, overheating and wear.

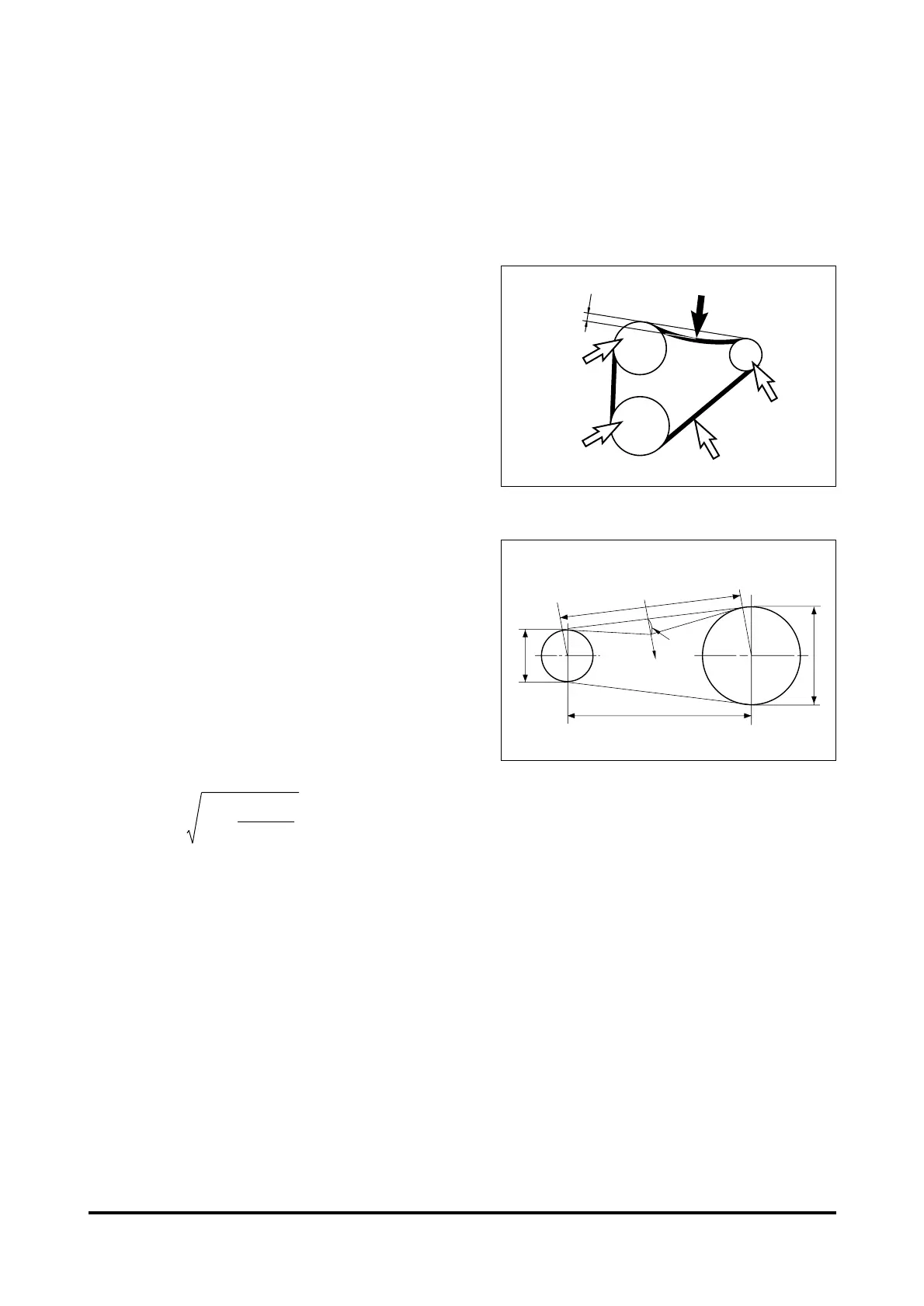

(3) Testing by hand

•

V-belt

The tension is correct if the V-belts can

be pressed in by about the thickness of

the V-belt. (no more midway between

the belt pulleys)

A more precise check of the V-belt

tension is possible only by using a V-

belt tension tester.

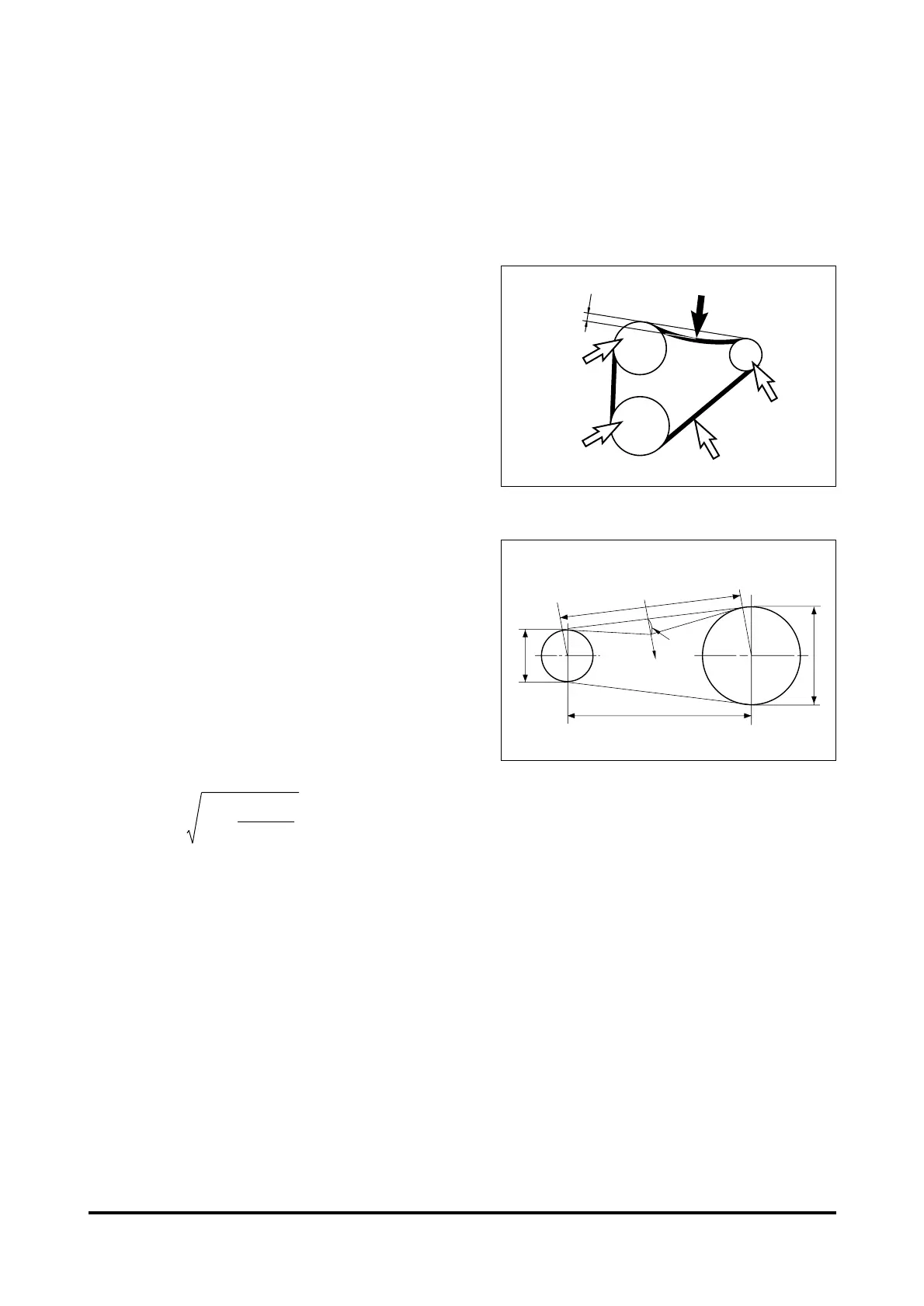

•

Poly belt

Poly belt will be properly tensioned if

the deflection force “F” is applied mid-

way between the belt’s tangent points

with the pulley.

T = 0.015 x S (about 1.5mm per 100mm)

T = 0.015 x *S (mm)

(T : Deflection, S : Span )

*S = C

2

- (mm)

- 172 -

MAINTENANCE OF MAJOR COMPONENTS

(D-d)

2

2

C : Distance of pulleys (mm),

D : Large pulley diameter (mm),

d : Small pulley diameter (mm)

Loading...

Loading...