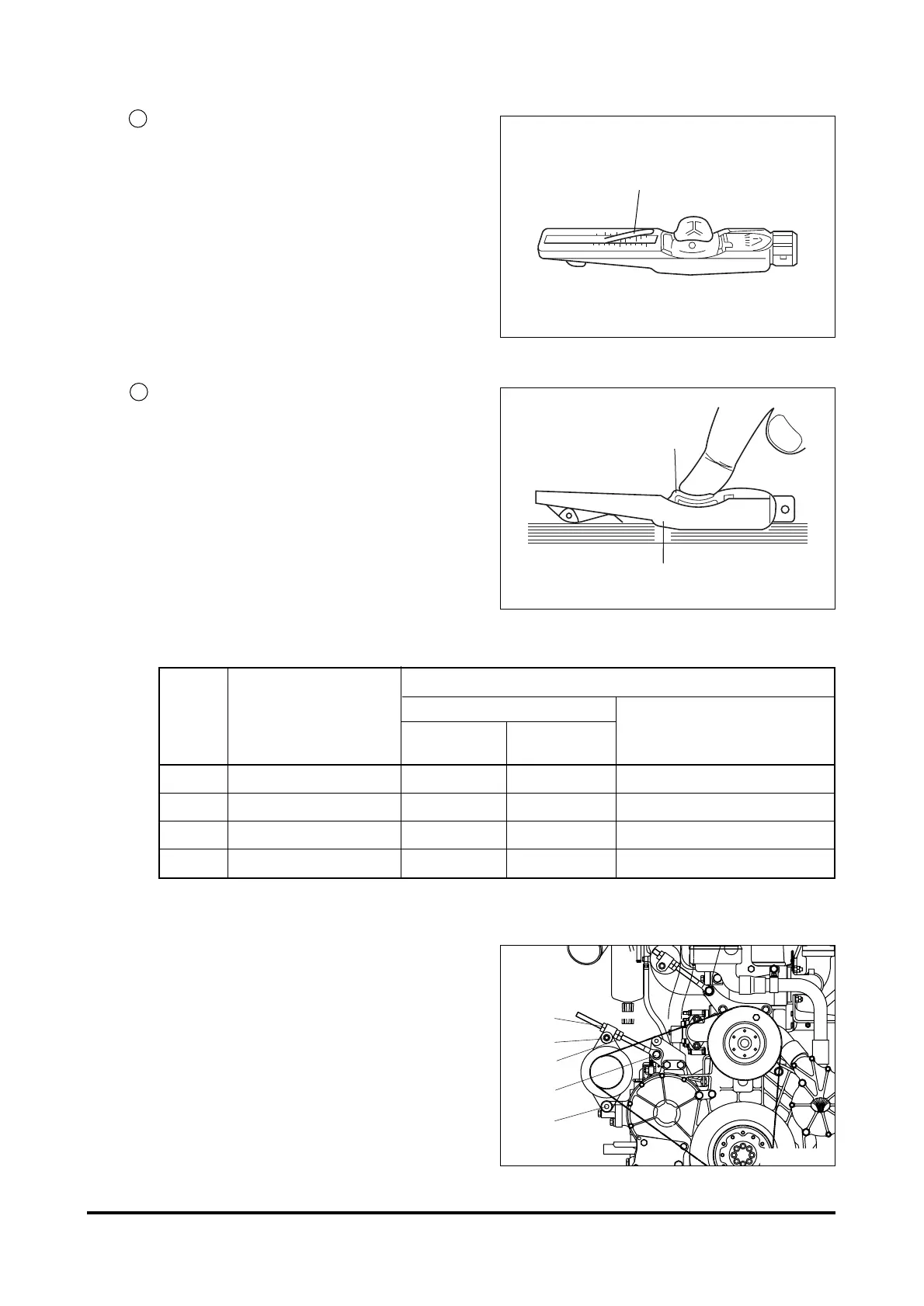

4) Measuring tension

Lower indicator arm (1) into the scale.

•

Apply tester to belt at a point midway

between two pulleys so that edge of

contact surface (2) is flush with the V-

belt.

•

Slowly depress pad (3) until the

spring can be heard to disengage.

This will cause the indicator to move

upwards. If pressure is maintained

after the spring has disengaged a

false reading will be obtained!

Reading of tension

•

Read of the tensioning force of the

belt at the point where the top sur-

face of the indicator arm (1) inter-

sects with the scale.

•

Before taking readings make ensure

that the indicator arm remains in its

position.

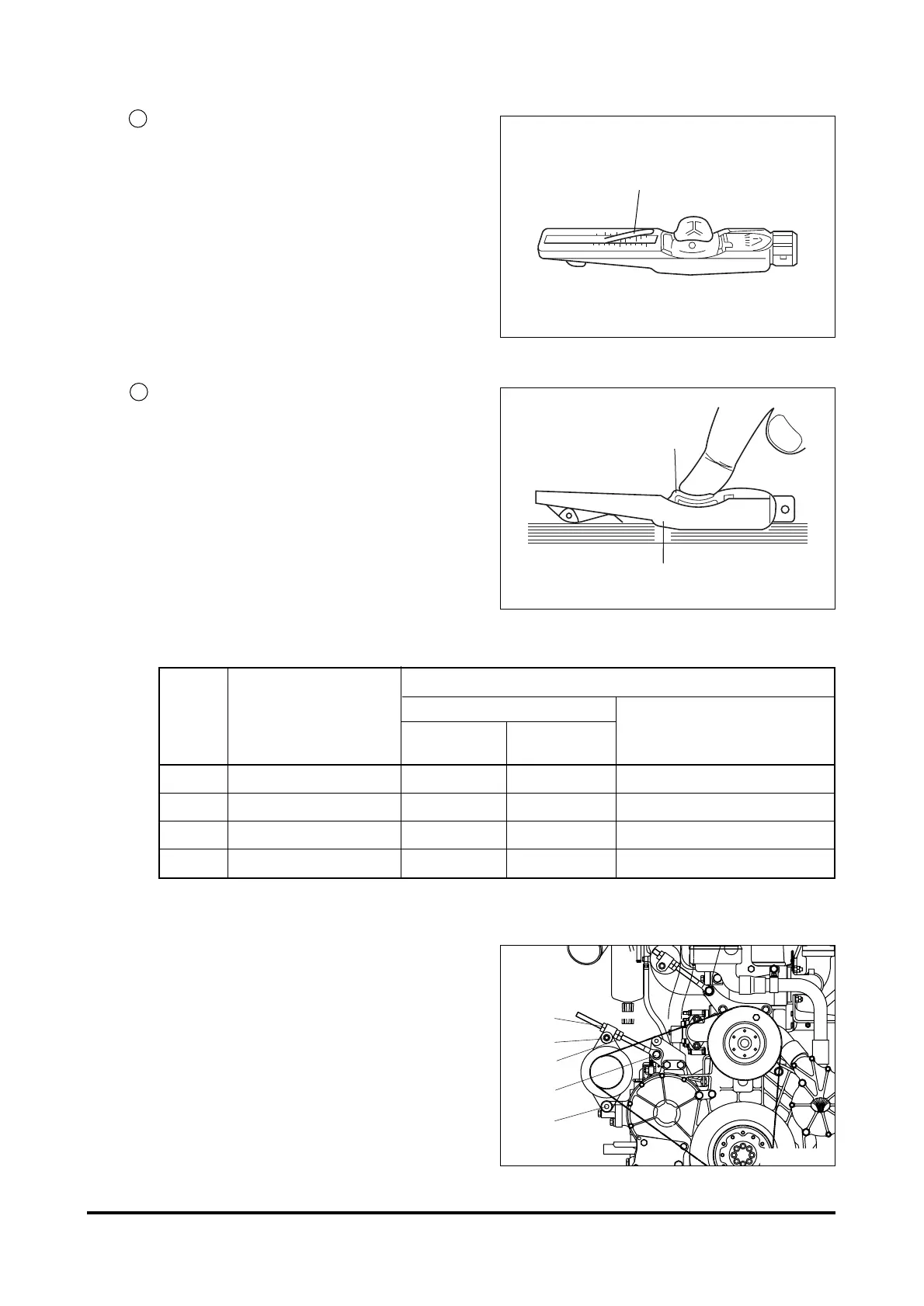

(5) Tensioning and changing V-belt

•

Remove fixing bolts. (1)

•

Remove lock nut. (2)

•

Adjust nut (3) until V-belts have cor-

rect tensions.

•

Retighten lock nut and fixing bolts.

To change the V-belts loosen mounting

bolts (1) and lock nut (2) and push ten-

sion pulley inwards by turning adjust-

ing nut (3).

- 173 -

MAINTENANCE OF MAJOR COMPONENTS

Tensioning forces on the tester

Type Drive belt width

new installation

When servicing after

Installation

After 10 min.

long running time

running time

M 9.5 mm 50 kg 45 kg 40 kg

A 11.8 mm 55 kg 50 kg 45 kg

B 15.5 mm 75 kg 70 kg 60 kg

C 20.2 mm 75 kg 70 kg 60 kg

Loading...

Loading...